A kind of environmental protection aerated brick short-cycle production line and its production process

A production process and technology of aerated bricks, applied in the field of green building materials, can solve problems such as lengthening stirring time, insufficient mixing of auxiliary materials and slurry, and reducing production efficiency, so as to increase feeding efficiency, improve production continuity, and improve production efficiency. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following is attached Figure 1-5 The application is described in further detail.

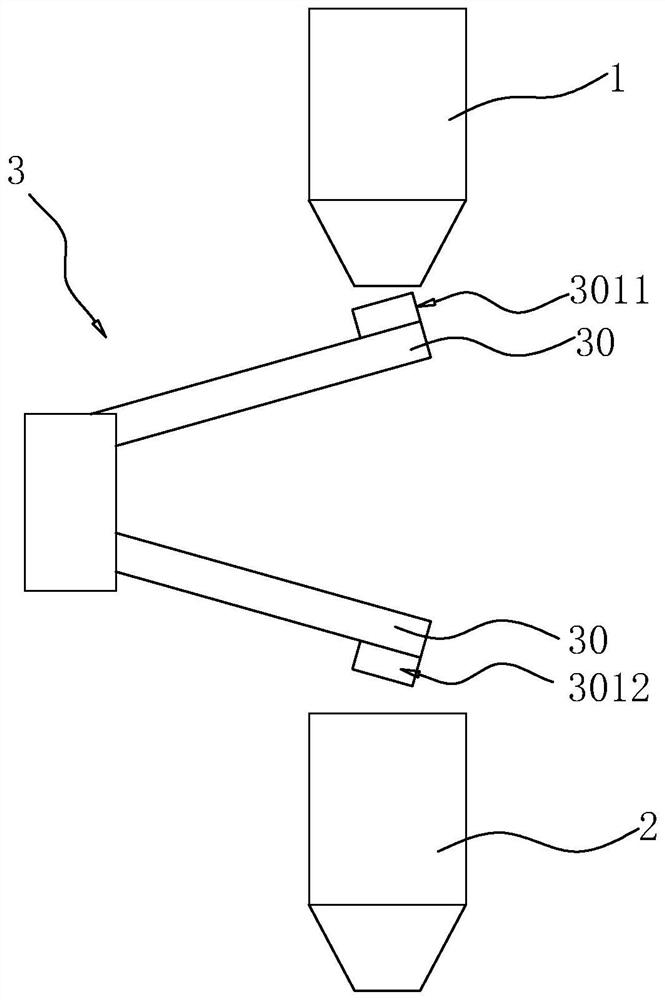

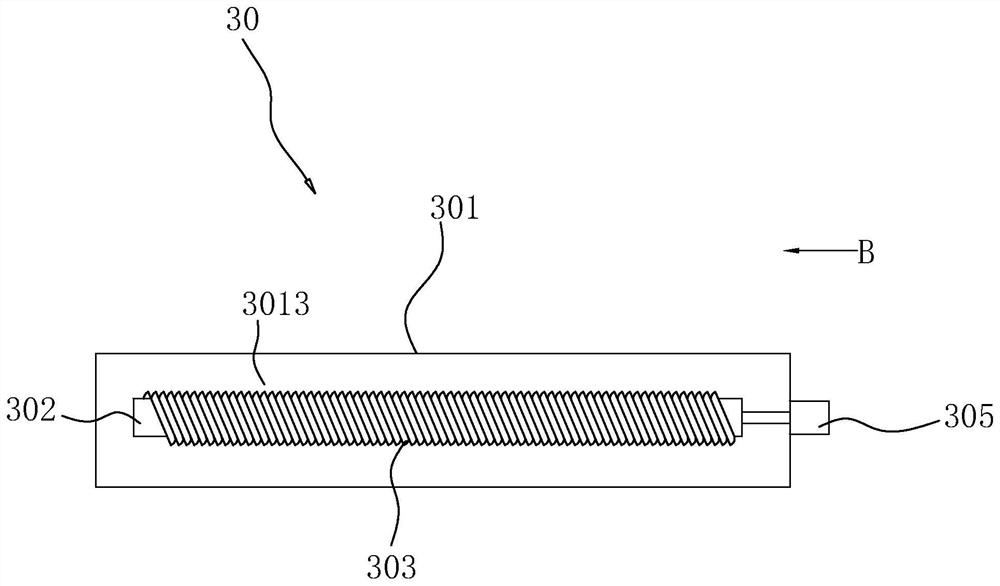

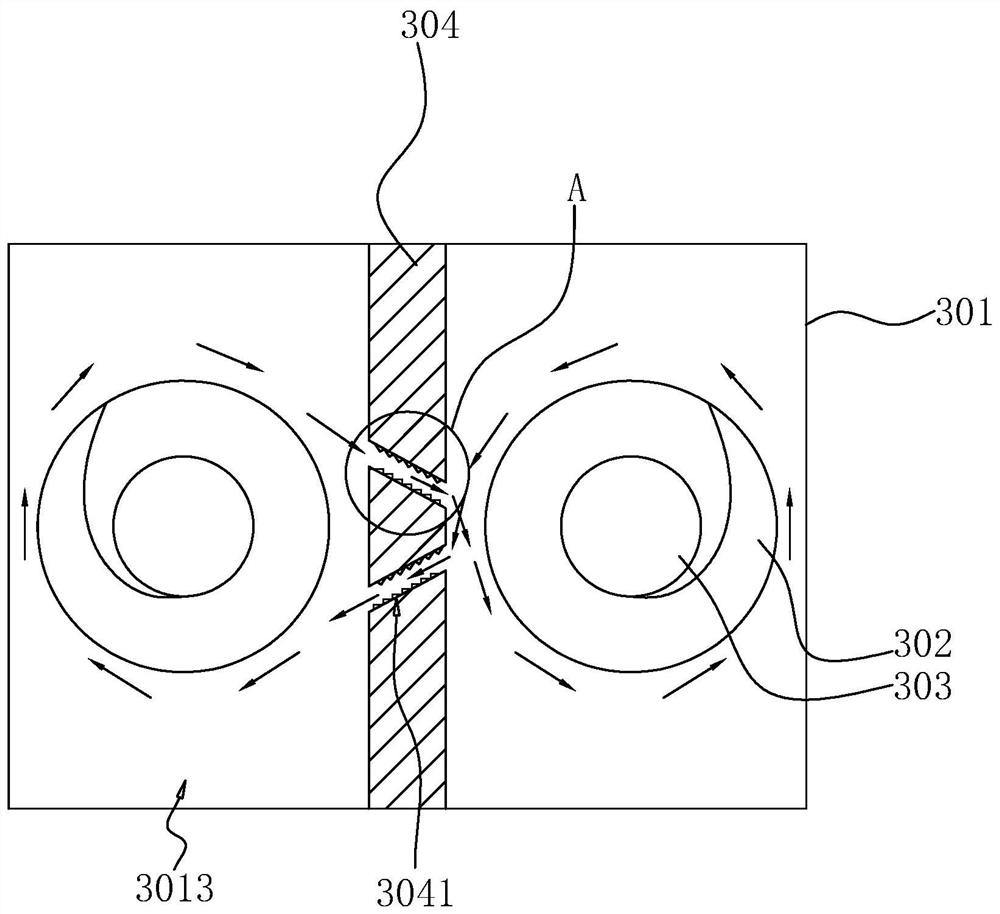

[0053] The embodiment of the present application discloses a short-cycle production line for environment-friendly aerated bricks. refer to figure 1 , a short-cycle production line of environmentally friendly aerated bricks, a first mixing zone 1, a second mixing zone 2 and a transfer zone 3. Wherein, the first stirring zone 1 is used to stir the slurry for the first time; the second stirring zone 2 is used to stir the slurry for the second time; the transfer zone 3 is used to transfer the slurry from the first stirring zone 1 to Second stirring zone 2. The first stirring zone 1 and the second stirring zone 2 can be selected as stirring tanks, and the stirring tanks are in the prior art, and will not be repeated here.

[0054]In actual production, the first stirring zone 1 is placed on three or more floors, the second stirring zone 2 is placed one floor below the first stirring zo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com