Stirring equipment with premixing function for battery production

A mixing equipment and premixing technology, which is applied in the direction of mixer accessories, mixers, electrode manufacturing, etc., can solve the problems of inconvenient mixing, affecting efficiency, prolonging processing time, etc., achieve novel structure, improve work efficiency, shorten mixing and mixing The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

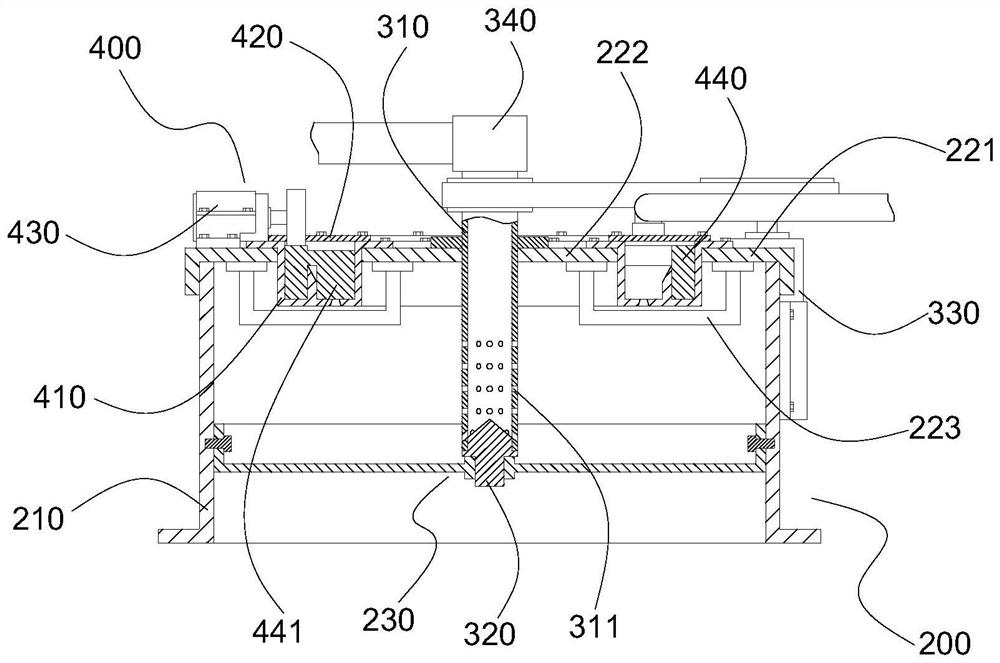

[0025] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

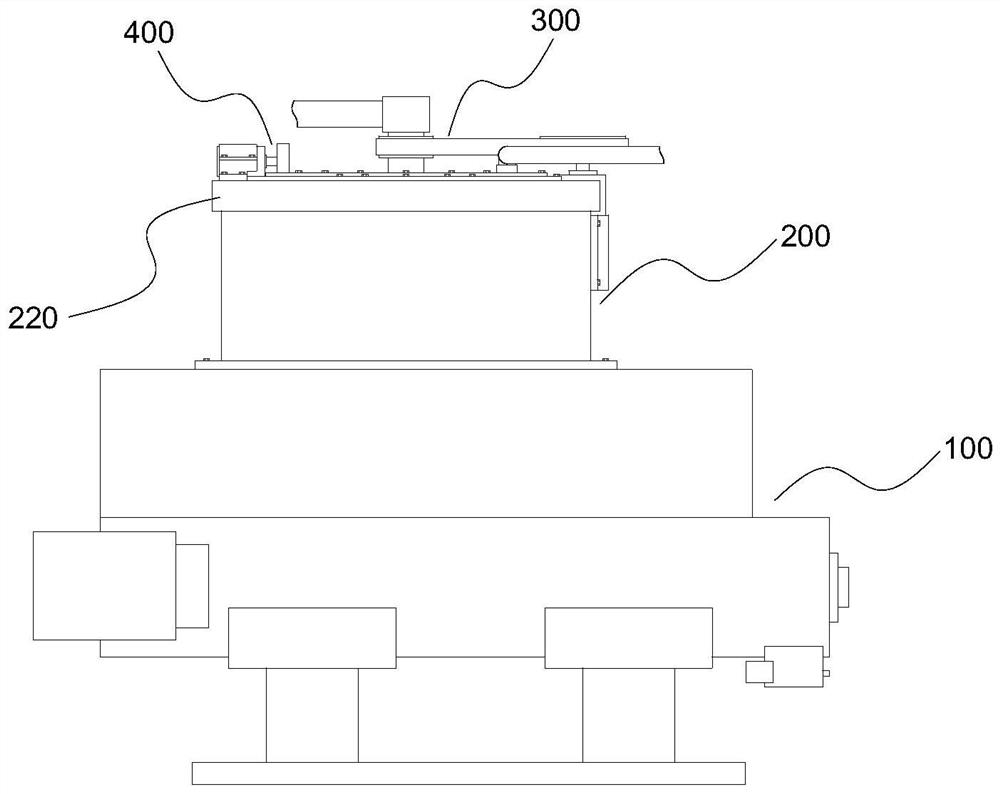

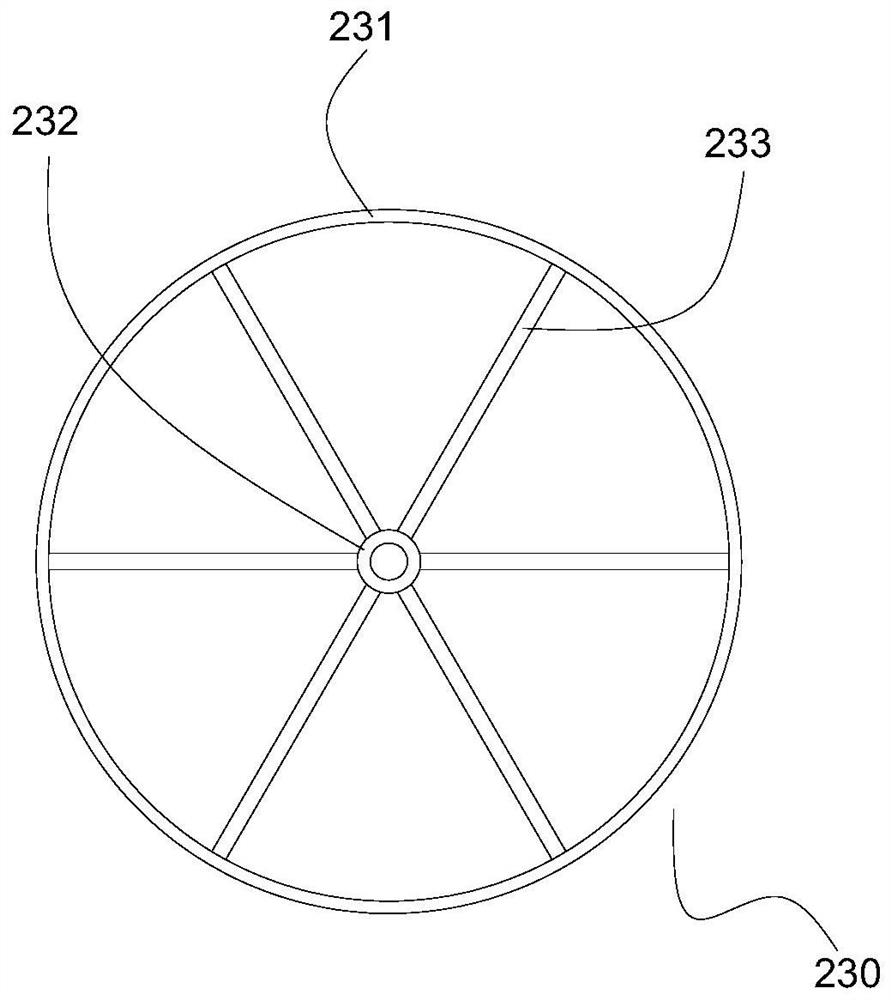

[0026] like figure 1 , figure 2 As shown, a specific embodiment of the present invention discloses a mixing device for battery production with a premixing function, including a screw mixer body 100, a premixing device 200 installed on the top of the screw mixer body 100, and the premixing device 200 includes The liquid feeding mechanism 300 and the powder feeding mechanism 400; the liquid feeding mechanism 300 includes a liquid spraying pipe 310, the liquid spraying pipe 310 is penetrated in the middle of the powder feeding mechanism 400, and the liquid spraying pipe 310 can spray liquid around the outside of the bottom; the powder feeding The mechanism 400 can feed downward, and the feeding area has a circular outline, and the dropped powder is contacted and premixed with the liquid that spreads around.

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com