Activated plant fiber, preparation method thereof and application of activated plant fiber in polylactic acid composite material

A plant fiber and composite material technology, applied in plant fibers, fiber processing, textiles and papermaking, etc., can solve the problem of difficult to coordinate the interface bonding between hydrophilic plant fibers and hydrophobic polylactic acid matrix, and achieve excellent activation effect, increase Triggers active, small range of motion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of the activated sisal fiber is as follows: the sisal fiber is cut into short fibers of 1mm, and dried to a moisture content of 0.9wt%, and then soaked in the lithium chloride / DMAc system at 80°C for 3h to dissolve the surface The activated sisal fiber is obtained by keeping the lithium chloride / DMAc system, wherein the lithium chloride content in the lithium chloride / DMAc system is 5 wt%.

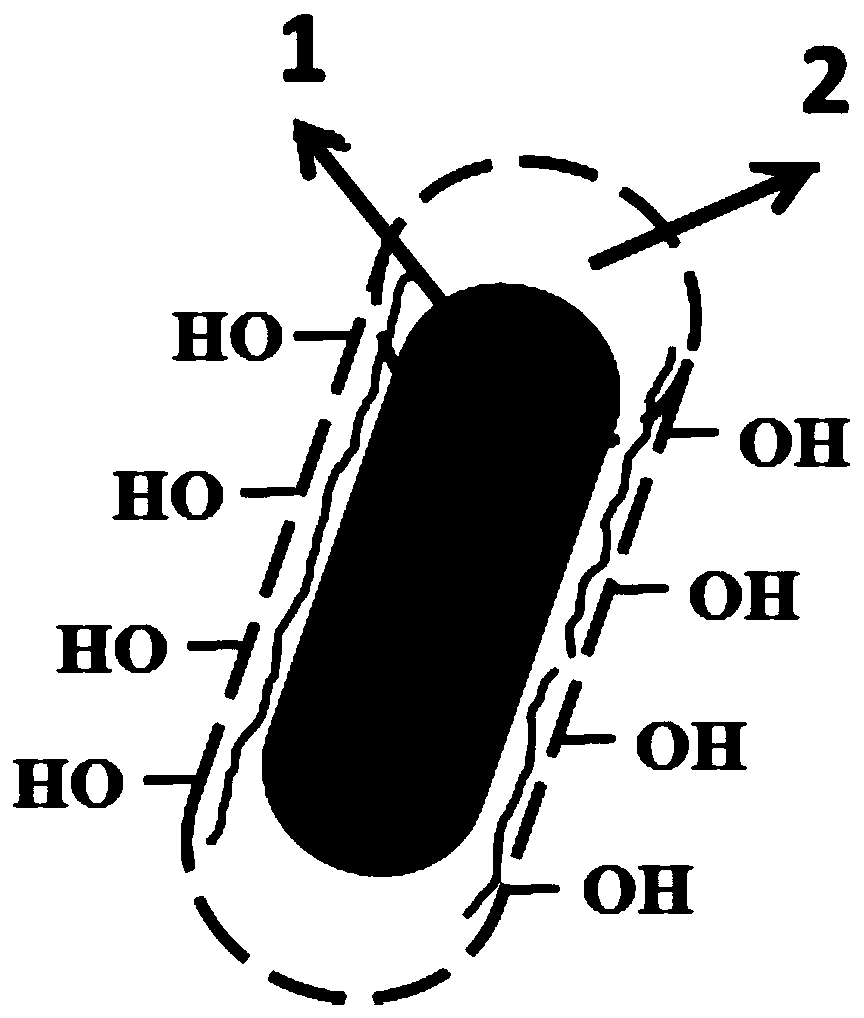

[0045] The final activated sisal fiber is as figure 1 As shown, it is mainly composed of undissolved sisal fiber body 1 and a coating layer 2 attached to the surface of the sisal fiber body after being dissolved by a solvent. Molecular solution, which is connected with the sisal fiber body through physical and chemical bonds.

Embodiment 2

[0047] The preparation method of the activated bamboo fiber is as follows: the bamboo fiber is cut into short fibers of 2mm, and dried to a moisture content of 0.8wt%, and then soaked in a lithium chloride / DMAc system at 100°C for 2 hours to dissolve the surface and retain chlorine. Lithium chloride / DMAc system was used to obtain activated bamboo fibrils, wherein the content of lithium chloride in the lithium chloride / DMAc system was 12 wt%.

[0048] The final activated bamboo fiber is mainly composed of the bamboo fiber body and the wrapping layer wrapped on the surface of the bamboo fiber body. The wrapping layer is a polymer solution that dissolves bamboo cellulose, lignin and hemicellulose. connected by physical and chemical bonds.

Embodiment 3

[0050] The preparation method of the activated straw fiber is as follows: cutting the straw fiber into short fibers of 5 mm, drying to a moisture content of 0.8 wt%, and then soaking in 1-butyl-3-methylimidazolium chloride salt at 120°C for 0.5 h After the surface is dissolved, the 1-butyl-3-methylimidazolium chloride salt is retained to obtain the activated straw fiber.

[0051] The final activated straw fiber is mainly composed of the straw fiber body and the coating layer wrapped on the surface of the straw fiber body. The coating layer is a polymer solution in which straw cellulose, lignin and hemicellulose are dissolved. connected by physical and chemical bonds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com