Lithiated vulcanized polyacrylonitrile, preparation method thereof, positive pole plate and lithium-sulfur secondary battery

A technology for vulcanizing polyacrylonitrile and polyacrylonitrile molecular structure, which is applied in the direction of secondary batteries, battery electrodes, non-aqueous electrolyte battery electrodes, etc., and can solve the problems of unfavorable high energy density lithium-sulfur secondary batteries, low active material loading, etc. problems, to achieve the effect of increasing sulfur loading and capacity per unit area, and optimizing preparation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of sulfur active material S1#:

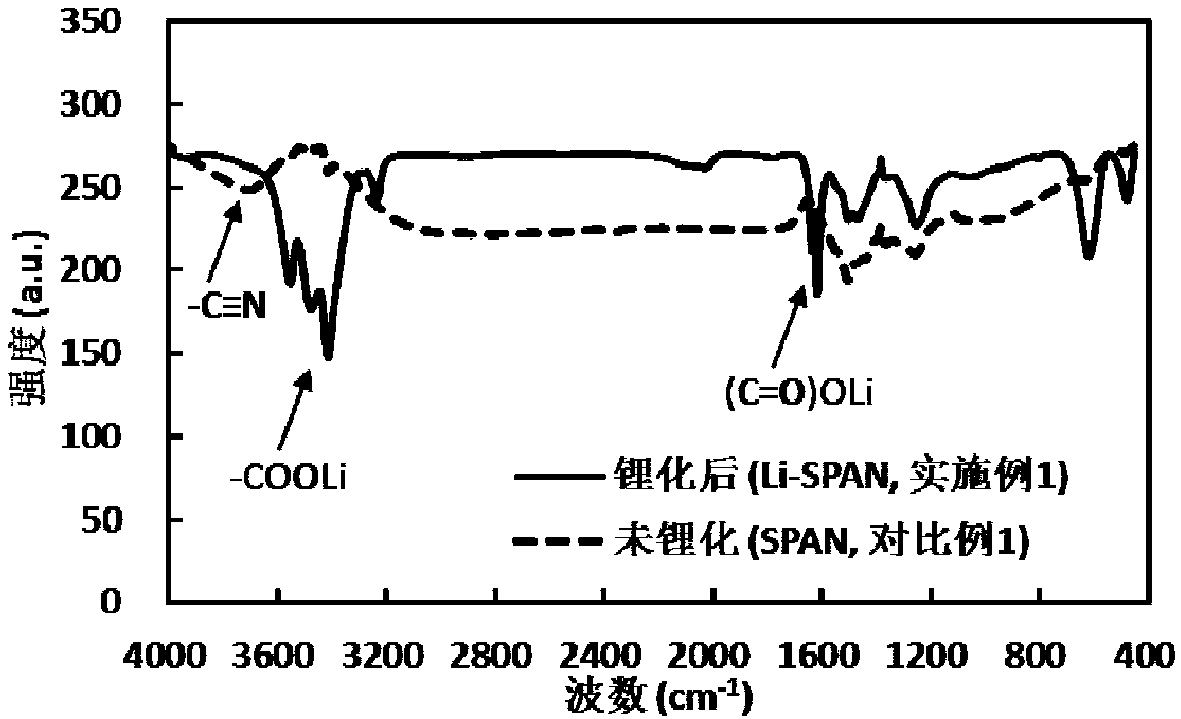

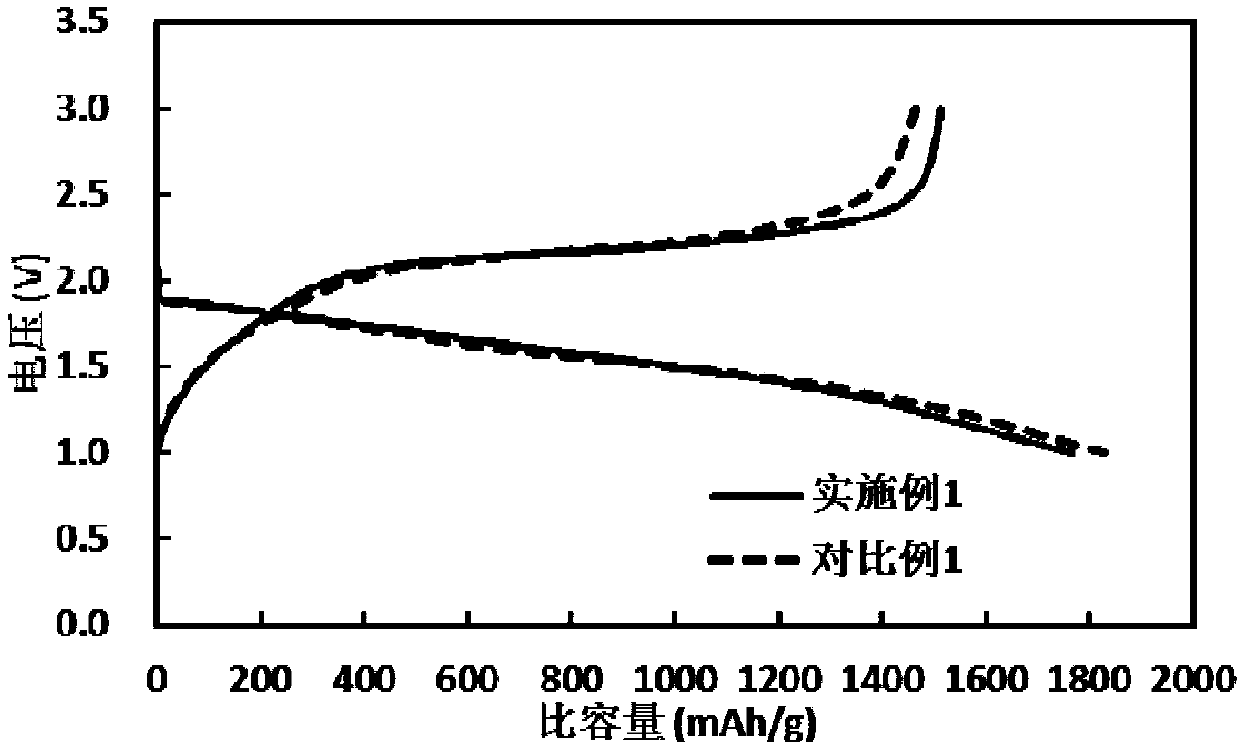

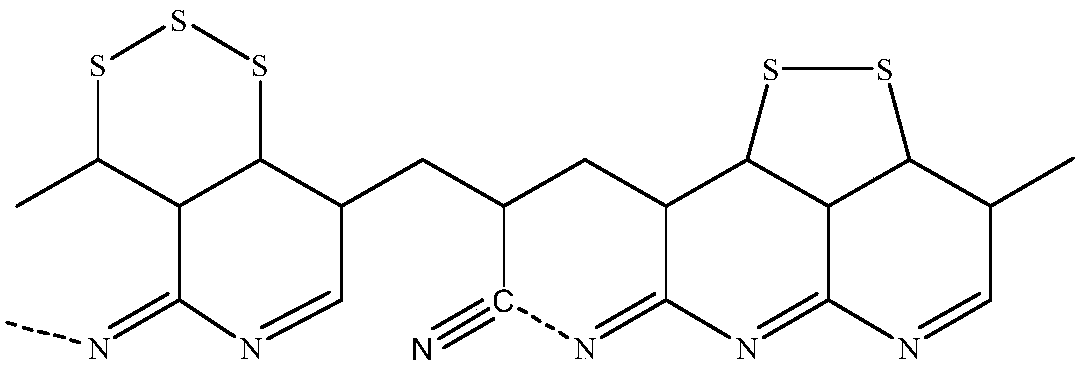

[0045] (1) Evenly mix elemental sulfur and polyacrylonitrile (molecular weight: 150,000) in a mortar at a mass ratio of 8:1, mix with an appropriate amount of ethanol, and ball mill for two hours. After the material is dried in a blast oven at 60°C, it is calcined at 300°C for 10 hours under the protection of nitrogen atmosphere, so that the main chain of the acrylonitrile polymer undergoes dehydrogenation reaction to form a matrix, and the elemental sulfur melts and polymerizes with the dehydrogenated acrylonitrile Sulfurized polyacrylonitrile material (SPAN) was obtained by compounding the material matrix, and the elemental analyzer (EA, Perkin Elmer PE2400II) was used to test that the mass content of sulfur (S) element was 45%, and the total mass content of nitrogen (N) element was 11%. X-ray photoelectron spectroscopy (XPS, AXIS ULTRA DLD) was used to analyze the change of the nitrogen content of the cyano group in the vu...

Embodiment 2

[0051] Preparation of sulfur active material S2#: the same process as described in Example 1.

[0052] Preparation of the positive electrode sheet P2#: the same as the positive electrode sheet preparation method described in Example 1, the difference is that the mass ratio of the binder PAA / P (HEA-co-DMA) and graphene in the conductive adhesive is replaced by 1:1 It is 1:3, and the positive plate is recorded as P2#.

[0053] Preparation of lithium-sulfur secondary battery C2#: the same process as described in Example 1.

Embodiment 3

[0055] Preparation of sulfur active material S3#: the same process as described in Example 1.

[0056] Preparation of the positive electrode sheet P3#: same as the method for preparing the positive electrode sheet described in Example 1, the difference is that the mass ratio of the binder PAA / P (HEA-co-DMA) to graphene in the conductive adhesive is replaced by 1:1 It is 3:1, and the positive plate is recorded as P2#.

[0057] Preparation of lithium-sulfur secondary battery C3#: the same process as described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com