High-strength viscose fiber and production method thereof

A viscose fiber, production method technology, applied in the direction of cellulose/protein conjugated rayon, rayon made of viscose, etc., can solve the problems of affecting the appearance of the fabric, difficulty in recycling, inability to scrub strongly, etc. Excellent hygroscopicity and wearing comfort, controllable operation process, simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

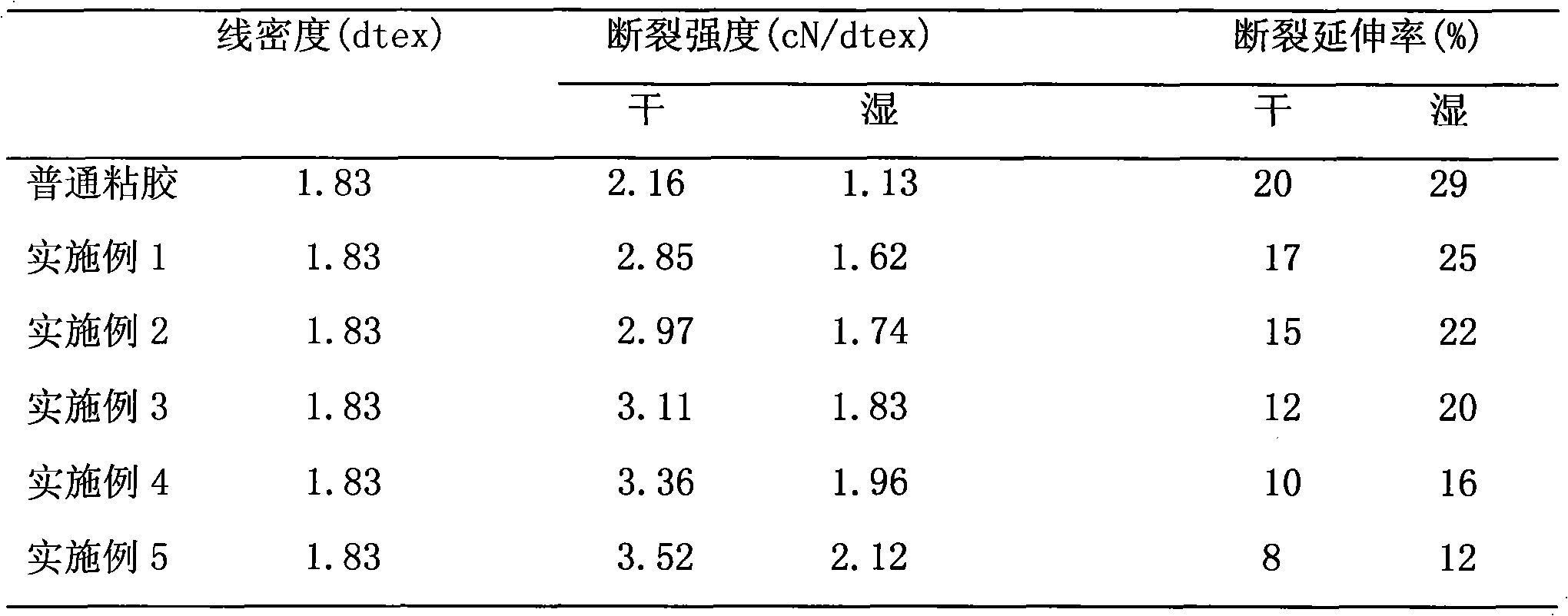

Embodiment 1

[0036] A kind of production method of high-strength viscose fiber, the bacterial cellulose of flake is placed in the vacuum oven of 100 ℃, bakes to constant weight; Then add the concentration and be 5% ethylenediamine solution After being mechanically stirred at room temperature for 2 hours, wash with distilled water first, then soak in ethanol for 3 times, each time for 30 minutes, and then bake in a vacuum oven at 100°C to constant weight; use the ball milling method to pulverize the above-mentioned sheet-shaped bacterial cellulose to obtain micro Nano-scale bacterial cellulose powder, under the action of ultrasonic waves, gradually add 2 grams of bacterial cellulose powder to 1000 grams of viscose spinning solution with a concentration of 10%, to obtain a mixed solution of the two, and then continue to Disperse for 50 minutes under the action of ultrasonic waves to obtain a uniformly dispersed mixed solution, vacuum defoam the mixed solution for 14 hours, and then use ordina...

Embodiment 2

[0038] A kind of production method of high-strength viscose fiber, place bacterial cellulose sheet in the vacuum oven of 80 ℃, dry to constant weight; Then add concentration and be in the ethylenediamine solution of 6%, the room temperature mechanical stirring process 1.5 After h, wash with distilled water first, then soak in ethanol for 3 times, each time for 30 minutes, filter and bake in a vacuum oven at 80°C to constant weight; use ball milling method to crush the above-mentioned flake bacterial cellulose to obtain micronano-scale bacterial fibers Plain powder, under the action of ultrasound, gradually add 4 grams of bacterial cellulose powder to 1000 grams of viscose solution with a concentration of 10%, to obtain a mixed solution of the two, and then continue to disperse for 60 minutes under the action of ultrasound to obtain Disperse the mixed solution evenly, vacuum defoam the mixed solution for 14 hours, and then adopt the production equipment and process of ordinary v...

Embodiment 3

[0040] A kind of production method of high-strength viscose fiber, place bacterial cellulose sheet in the vacuum oven of 90 ℃, dry to constant weight; Then add concentration and be 7% in the ethylenediamine solution, room temperature mechanical stirring process 1.2 After h, first wash with distilled water, then soak in ethanol for 3 times, each time for 30 minutes, filter and bake in a vacuum oven at 90°C to constant weight; use ball milling to pulverize the above-mentioned flake bacterial cellulose to obtain micronano-scale bacterial fibers Plain powder, under the action of ultrasound, gradually add 6 grams of bacterial cellulose powder to 1000 grams of viscose solution with a concentration of 10%, to obtain a mixed solution of the two, and then continue to disperse for 70 minutes under the action of ultrasound to obtain Disperse the mixed solution evenly, vacuum defoam the mixed solution for 14 hours, and then use ordinary viscose fiber production equipment and technology to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com