Carbon nanofiber aerogel as well as preparation method and application thereof

A carbon nanofiber and aerogel technology, which is applied in the field of nanomaterials to achieve the effects of good lipophilicity, cheap and easy-to-obtain raw materials, and convenient storage and transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention discloses a preparation method of carbon nanofiber airgel, comprising the following steps:

[0035] Step a) soaking the bacterial cellulose block in deionized water to remove acid to obtain a neutral bacterial cellulose block. The function of this step is to remove the acid liquid in the bacterial cellulose block, so as to prevent the acidic substance from reacting with the bacterial cellulose airgel in the subsequent high-temperature pyrolysis step. Since bacterial cellulose has a three-dimensional network structure and can be produced on a large scale, it is an ideal precursor for preparing carbon nanofiber aerogels. In order to make the pH value of the bacterial cellulose block close to neutral, the bacterial cellulose block may preferably be soaked in deionized water which is replaced every day for 3-7 days, more preferably for 5-6 days. Those skilled in the art can easily imagine that for the convenience of subsequent operations, the bacterial cellul...

Embodiment 1

[0043] Take a commercially purchased 320×240×12mm 3 Large pieces of bacterial cellulose were soaked in deionized water for 5 days, and the deionized water was replaced every day. Cut the large piece of neutral bacterial cellulose after deacidification into 50×20×12mm 3 The small pieces are ready to use.

[0044] The small pieces of neutral bacterial cellulose were frozen with liquid nitrogen for 25 minutes, and then transferred to a freeze dryer for 4 days to dry.

[0045] The BC airgel obtained by freeze-drying was placed in a ceramic boat and then transferred to a tube furnace. Pyrolysis under argon atmosphere, starting from room temperature at 20°C, heating at a rate of 2°C / min, reaching 500°C after 4 hours, keeping at 500°C for 1 hour, and then heating at a rate of 5°C / min to 1300°C, at Keep at 1300°C for 2 hours to fully pyrolyze. Then cool down to 500°C at 5°C / min, and finally cool down naturally to obtain black carbon nanofiber airgel.

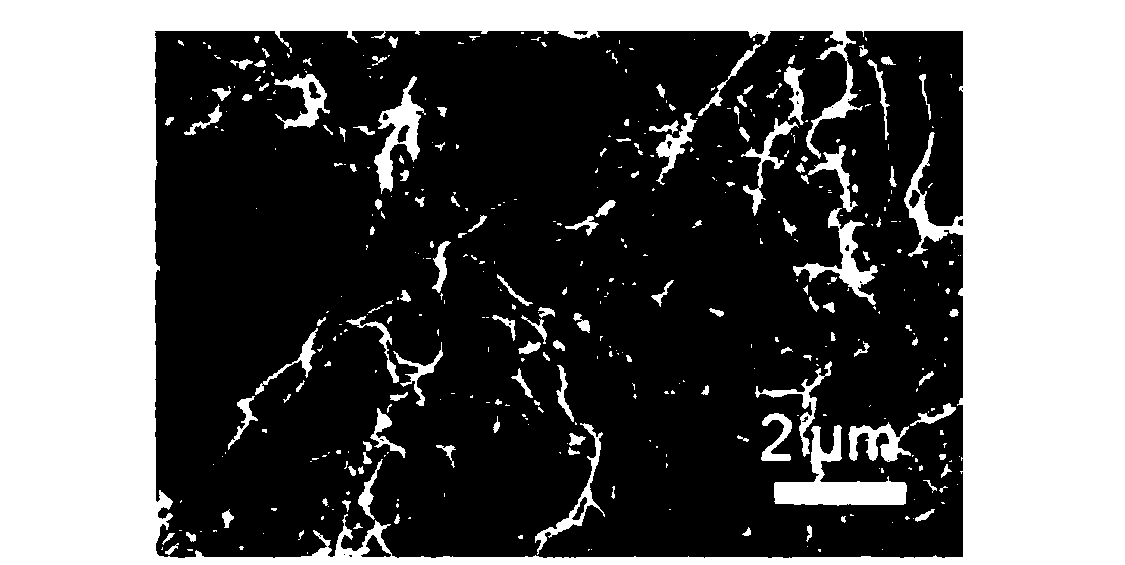

[0046] The density of the p...

Embodiment 2

[0049] Take a commercially purchased 320×240×12mm 3 Large pieces of bacterial cellulose were soaked in deionized water for 4 days, and the deionized water was changed every day. Cut the large piece of neutral bacterial cellulose after deacidification into 50×20×12mm 3 The small pieces are ready to use.

[0050] The small pieces of neutral bacterial cellulose were frozen with liquid nitrogen for 20 minutes, and then transferred to a freeze dryer to dry for 5 days.

[0051] The BC airgel obtained by freeze-drying was placed in a ceramic boat and then transferred to a tube furnace. Pyrolysis under nitrogen atmosphere, starting from room temperature 20°C, heating up to 400°C at a rate of 1°C / min, keeping at 400°C for 2 hours, then raising the temperature to 1000°C at a rate of 4°C / min, and keeping at 1000°C for 3 hours to fully decompose. Then cool down to 500°C at 4°C / min, and finally cool down naturally to obtain black carbon nanofiber airgel.

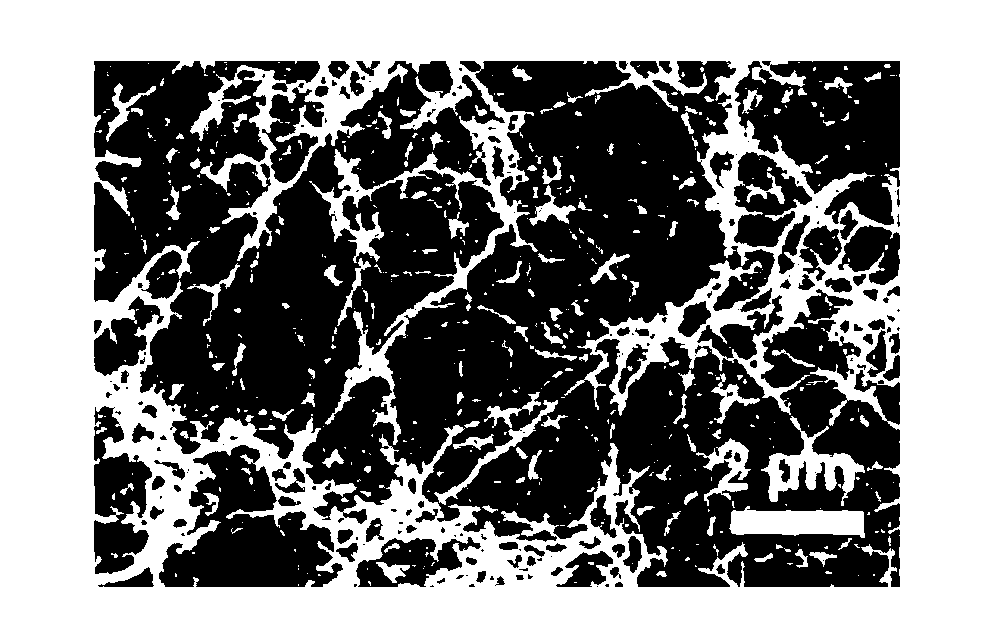

[0052] Such as image 3 As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com