Waste water purifying agent, and its preparing method and use

A purifying agent and wastewater technology, which is applied in chemical instruments and methods, water/sewage treatment, adsorbed water/sewage treatment, etc. It can improve the ability of removing oil pollution and various harmful impurities, improve the separation rate of free water, and improve the lipophilicity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Cationic attapulgite A1 Preparation of:

[0059]a. Sodium treatment: crush the attapulgite into finer than 150 mesh, and fully mix it with a sodium chloride (NaCl) solution with a concentration of 150 g / l. The weight ratio of NaCl to attapulgite is preferably 3:1. After fully stirring for 8 hours, solid-liquid separation was carried out, and the precipitate was washed, dried at 110°C, and crushed through a 200-mesh sieve.

[0060] b. Electrical property modification treatment: fully mix the sodium-treated attapulgite with an aluminum chloride (AlCl3) solution with a concentration of 0.5 mol / l. The weight ratio of AlCl3 to attapulgite is preferably 1:1. After fully stirring for 24 hours, solid-liquid separation was carried out, and the precipitate was washed, dried at 110°C, and crushed through a 200-mesh sieve.

[0061] c. Pore-forming treatment: mix paper scraps passed through a 60-mesh sieve with polyvinyl alcohol in a weight ratio of 2:1 as a porogen, and add the...

Embodiment 2

[0064] Preparation of activated alumina B1:

[0065] a. Wash and dry the glass and ceramics separately.

[0066] b. The above-mentioned glass and ceramics are respectively pulverized through a 200-mesh sieve.

[0067] c. Mix ceramic powder and glass powder in a ratio of 3:1 to obtain the activated alumina B2 .

Embodiment 3

[0069] activated silicate B2 Preparation of:

[0070] a. Take commercially available water glass (Na 2 SiO 3 or K 2 SiO 3 ), namely Na 2 O nSiO 2 or K 2 O nSiO 2 , where n is greater than or equal to 3. Press Al +3 : SiO 2 The water glass and the aluminum hydroxide solution are thoroughly mixed in a molar ratio of 1:1.

[0071] b. Add 15% sulfuric acid dropwise to the above mixture to adjust the pH to 3.6, and keep stirring for 8 hours. Solid-liquid separation is then performed. The acid is 15% sulfuric acid.

[0072] c. Dry the solid phase obtained in step b at 300°C for 2 hours, then cool and pulverize to obtain the activated silicate B2 .

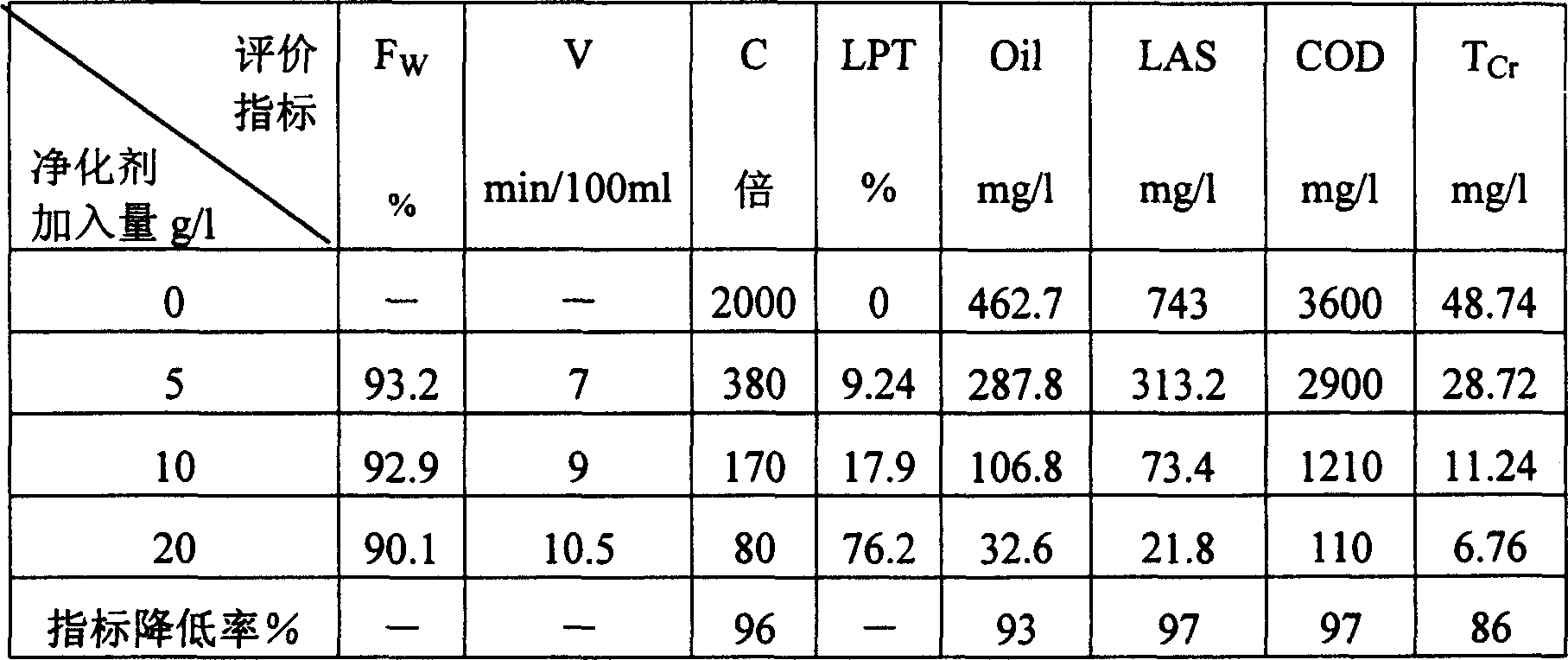

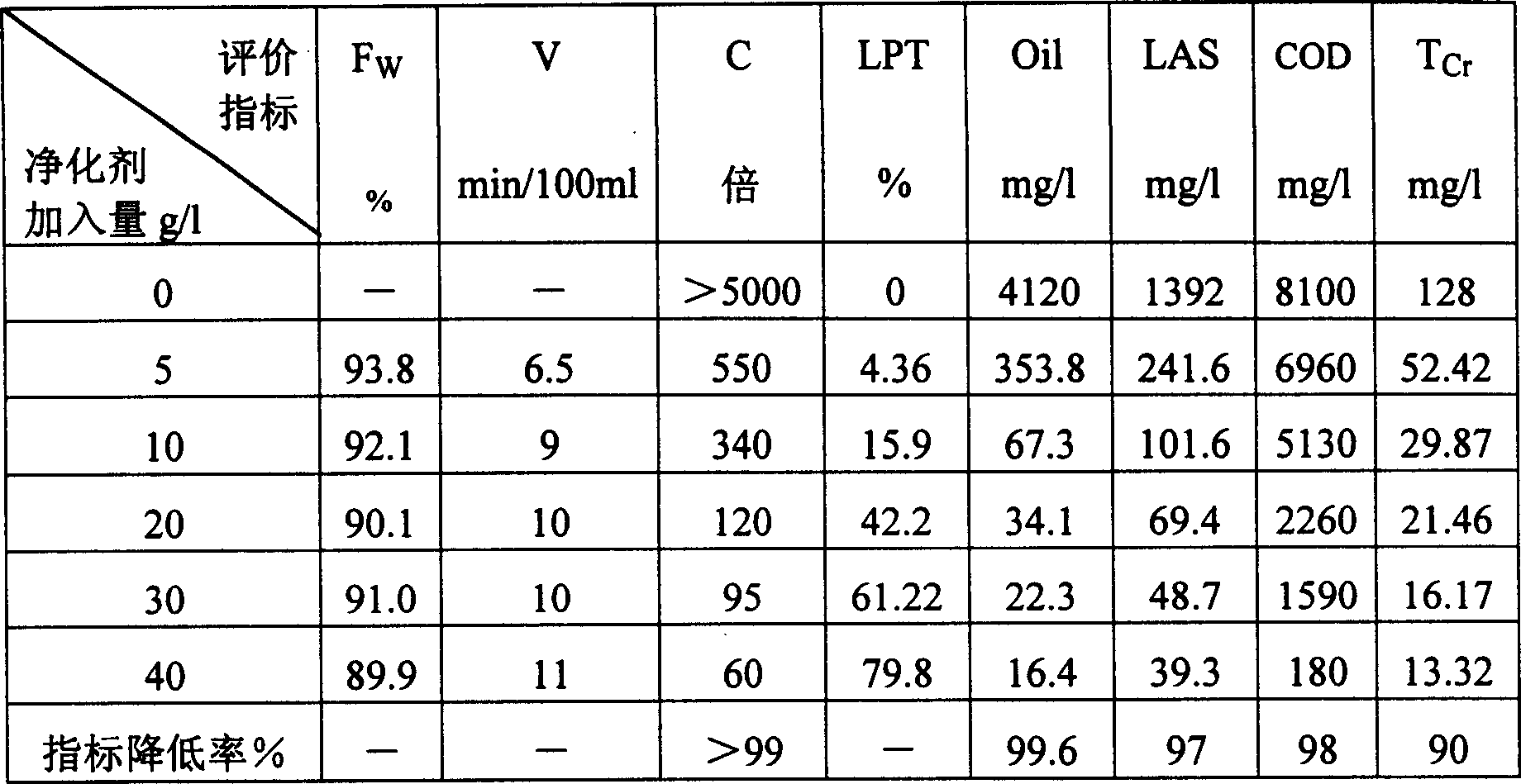

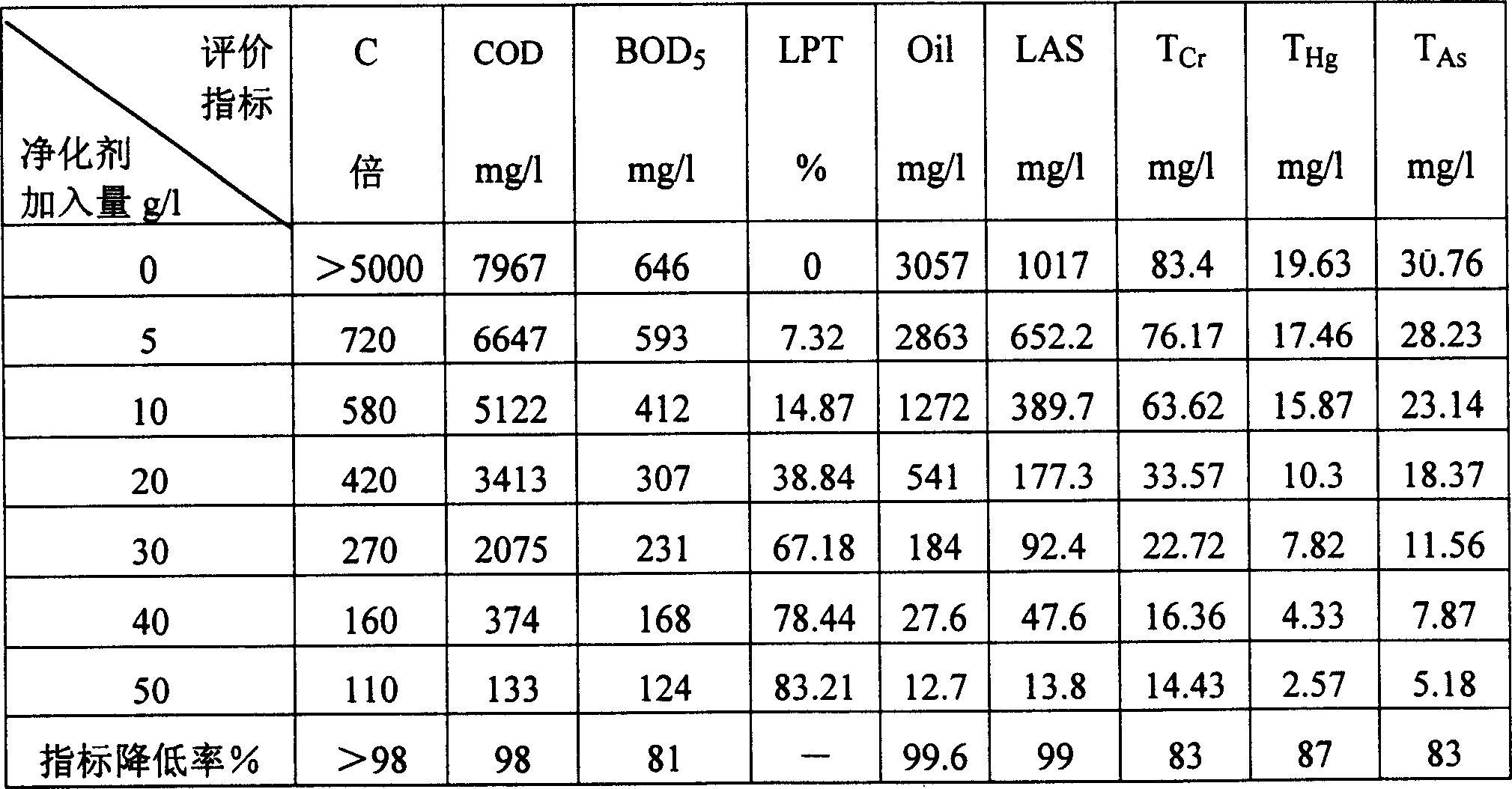

[0073] 2. Preparation of waste water purification agent and water treatment experiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com