Shaft spring of railway vehicle

A railway vehicle and shaft spring technology, which is applied in the field of railway vehicle shaft springs, can solve problems such as torsional deformation, impact, easy deterioration of durability, etc., and achieve the effects of reducing elastic force weakening, improving durability, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

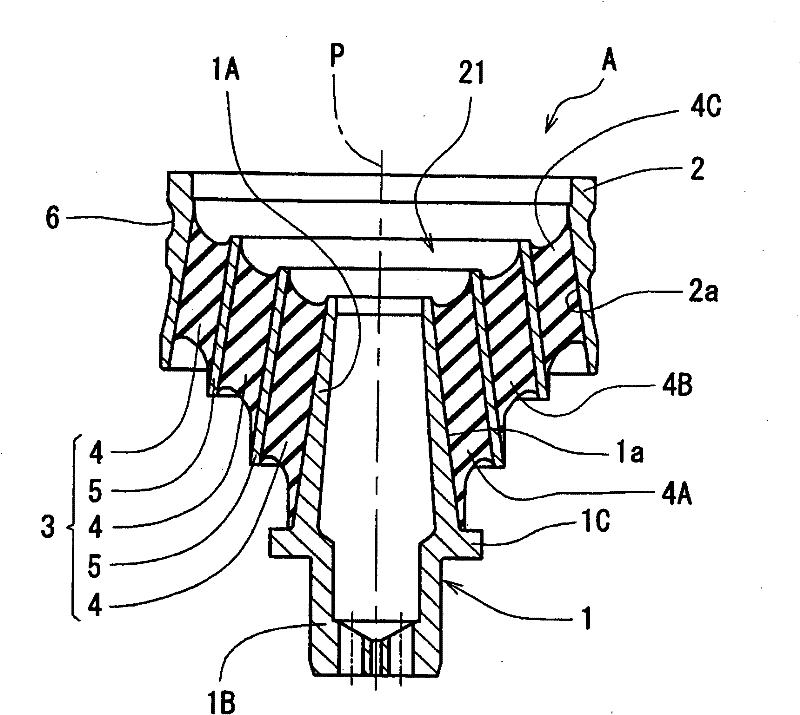

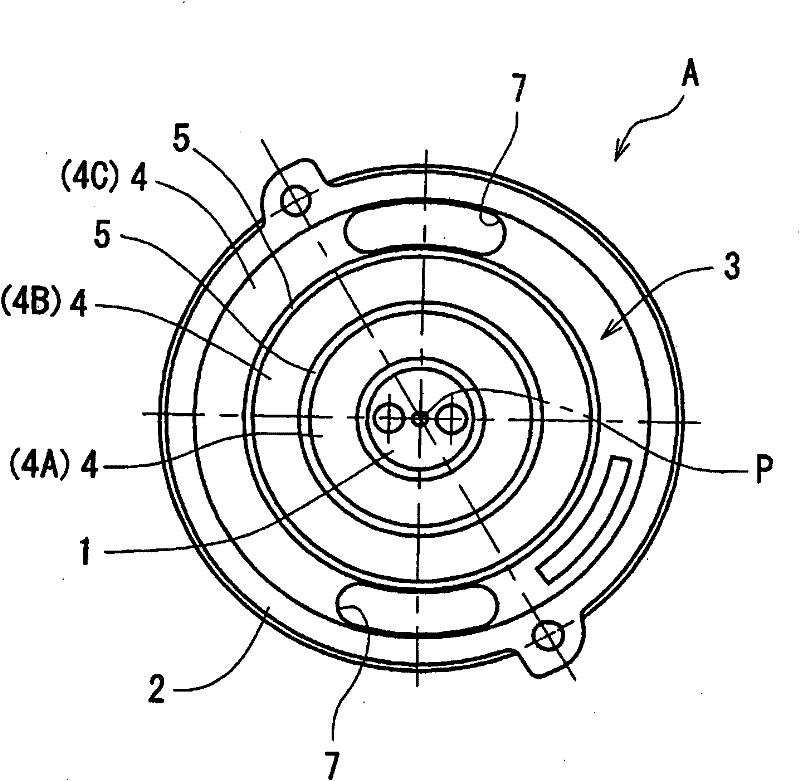

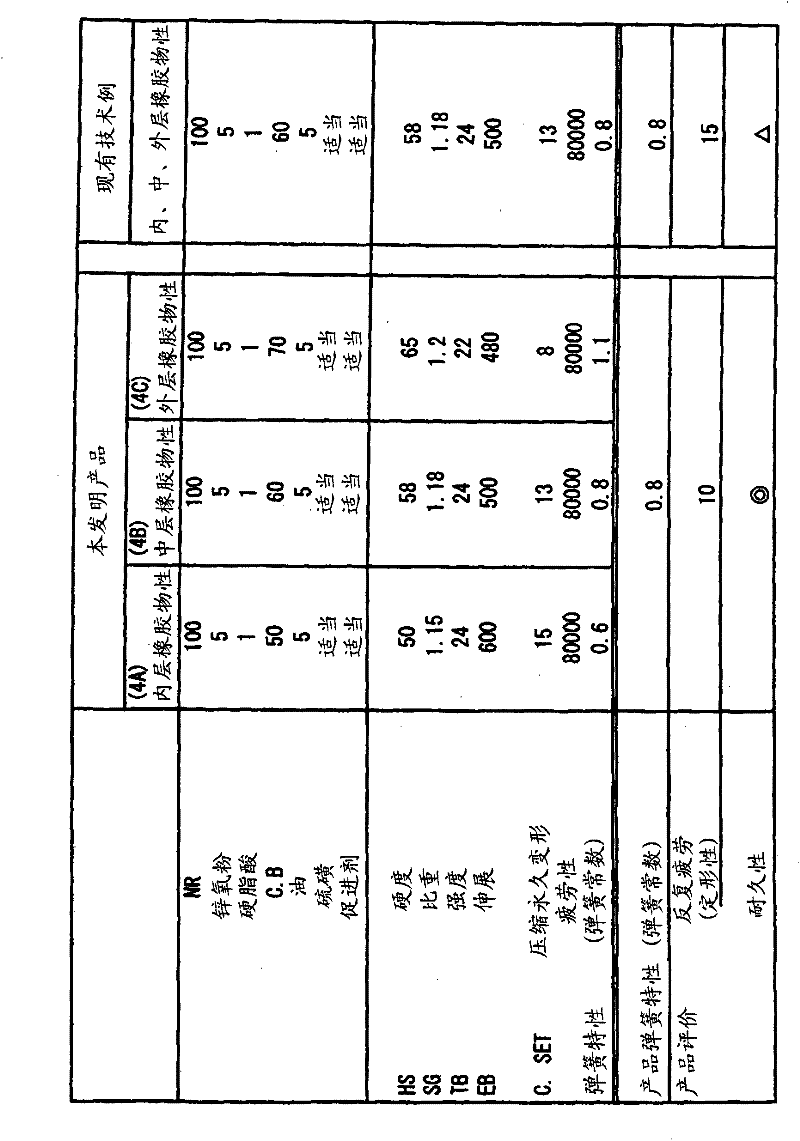

[0024] Such as figure 1 , figure 2 As shown, the railway vehicle axle spring A is configured to have: a main shaft 1, an outer cylinder 2 having the same (or substantially the same) longitudinal axis P as the main shaft 1, and formed to be concentric (or substantially concentric) with the longitudinal axis P. ) in the state of radially inwardly and outwardly laminating the laminated rubber structure of three layers of rubber layers 4 and two layers of hard partition walls (metal rings) 5, and the elastic part 3 sandwiched between the main shaft 1 and the outer cylinder 2. In the case where the radially inner and outer elastic portions 3 adopt a laminated rubber structure, the number of hard partition walls 5 is a value obtained by subtracting one from the number of rubber layers 4 .

[0025] The main shaft 1 is made of metal, and has a conical cylindrical shaft upper part 1A with an enlarged lower part, a cylindrical lower shaft part 1B with a solid circular cross-section wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com