Preparation method of biomimetic cartilage doped ordered magnetic nano-short fibers spliced double-layer hydrogel

A magnetic nano and short fiber technology, applied in the field of biomedical engineering, can solve problems such as poor mechanical properties, achieve low cost, excellent compression resistance, and promote cell proliferation and differentiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

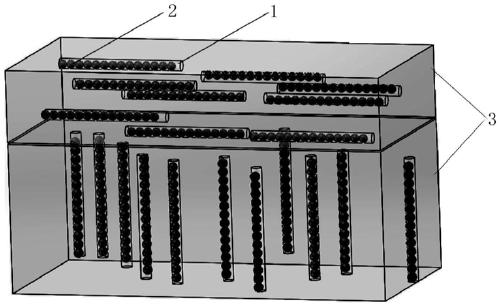

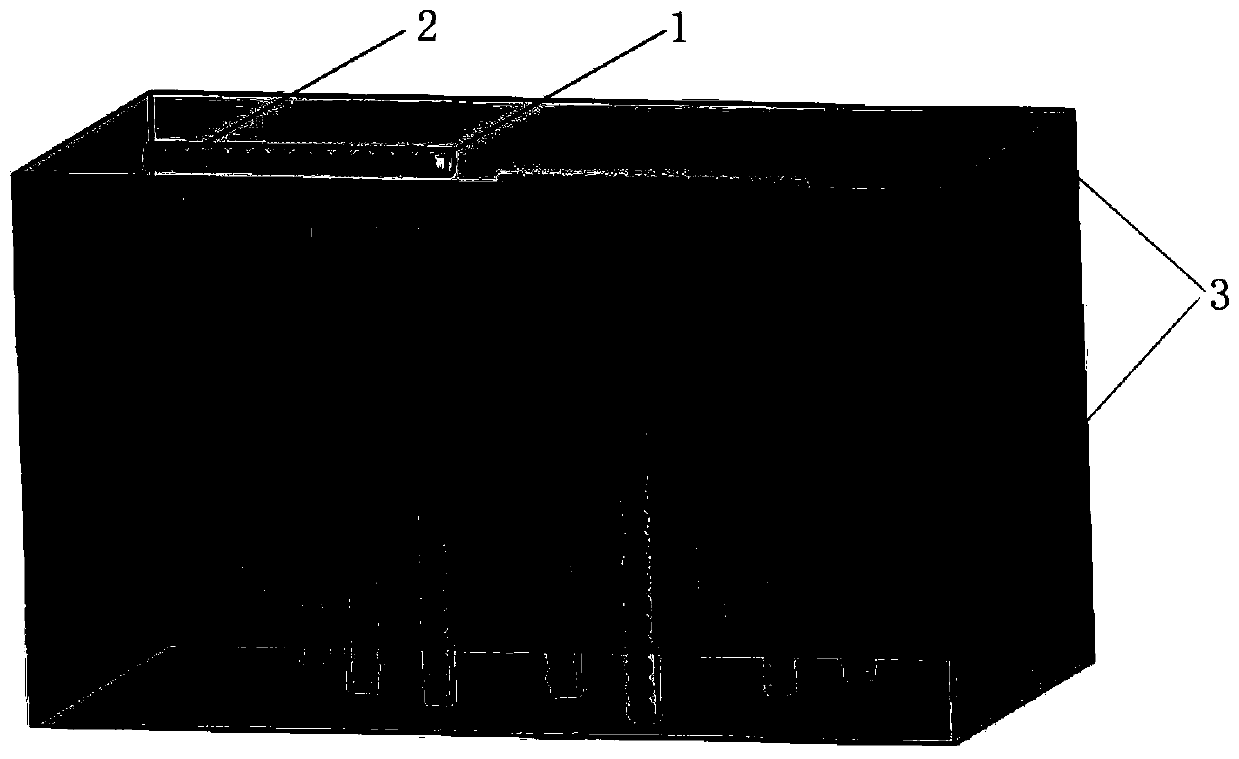

[0038] Example 1: Preparation of poly(lactic-co-glycolic acid) / polyacrylamide / sodium alginate biomimetic cartilage doped with ordered magnetic nano-short fibers spliced bilayer hydrogel

[0039] Prepare 24% (mass / volume) poly(lactic-co-glycolic acid) copolymer (molecular weight is 100,000) spinning solution, solvent is the mixed solution of N,N-dimethylformamide and dichloromethane (4 / 3, volume / volume ), mixed the ferroferric oxide magnetic particles with the spinning solution (magnetic particles: macromolecule = 1:5, mass: mass), stirred at room temperature for 5 hours, then ultrasonically dispersed for half an hour, and obtained magnetic nano Fiber membrane, where the solution flow rate is 0.2mL / h, the applied voltage is 12-14kV, and the needle-to-receiver distance is 12cm. Cut the magnetic nanofiber membrane into 1 × 1 cm 2of small pieces. Mix 1 g of cut short fiber film with ethanol solution, and stir for 5 minutes with a high-speed shear homogenizer with a rotating sp...

Embodiment 2

[0040] Example 2: Preparation of Polycaprolactone / Polyacrylamide Grafted Chitosan / Sodium Alginate Biomimetic Cartilage Doped with Ordered Magnetic Nano Short Fibers Splicing Bilayer Hydrogel

[0041] Prepare 14% (mass / volume) polycaprolactone spinning solution, solvent is the mixed solution (1 / 5, volume / volume) of methanol and chloroform, ferromagnetic particle is mixed with spinning solution (magnetic particle: Polymer=1:5, mass:mass), stirred at room temperature for 5 hours, then ultrasonically dispersed for half an hour, and obtained magnetic nanofibrous membrane by electrospinning technology, wherein the solution flow rate was 0.4mL / h, and the applied voltage was 15-19kV , the needle-to-receiver distance is 15 cm. Cut the magnetic nanofiber membrane into 1 × 1 cm 2 Mix 1 g of cut short fiber film with ethylene glycol solution, and stir for 5 minutes with a high-speed shear homogenizer with a rotation speed of 15,000 rpm, and the length of the short fiber obtained is less ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com