Fluororubber-metal laminate

A fluororubber and metal layer technology, applied in the field of fluororubber metal laminates, can solve problems such as unfavorable cost and large environmental load, and achieve the effects of reducing processing cost, prolonging service life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

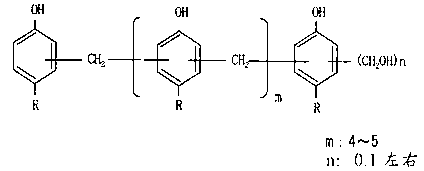

Method used

Image

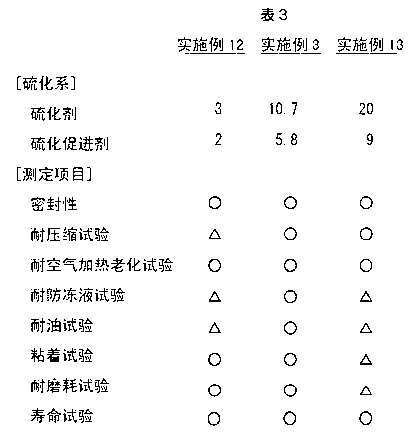

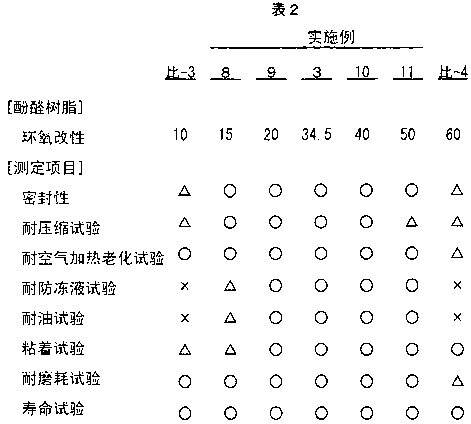

Examples

Embodiment 1~5

[0095] In Comparative Example 1, the amount of the epoxy group-containing silane coupling agent (SH-6040) was changed to 2, 3, 4.6, 7 or 9 parts by weight, respectively.

Embodiment 6

[0097] In Comparative Example 1, 5 parts by weight of a methacryloxy group-containing silane coupling agent (Toray Dow Corning product APZ6030) was used instead of the epoxy group-containing silane coupling agent.

Embodiment 7

[0099] In Comparative Example 1, instead of the epoxy group-containing silane coupling agent, 5 parts by weight of an acryloxy group-containing silane coupling agent (the product of the same company, KBM5103) was used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com