Polyolefin microporous film

A microporous film and polyolefin technology, applied in structural parts, battery pack parts, electrochemical generators, etc., can solve the problems of lower battery productivity, short circuit, drop, etc., and achieve excellent self-discharge characteristics and compression resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12

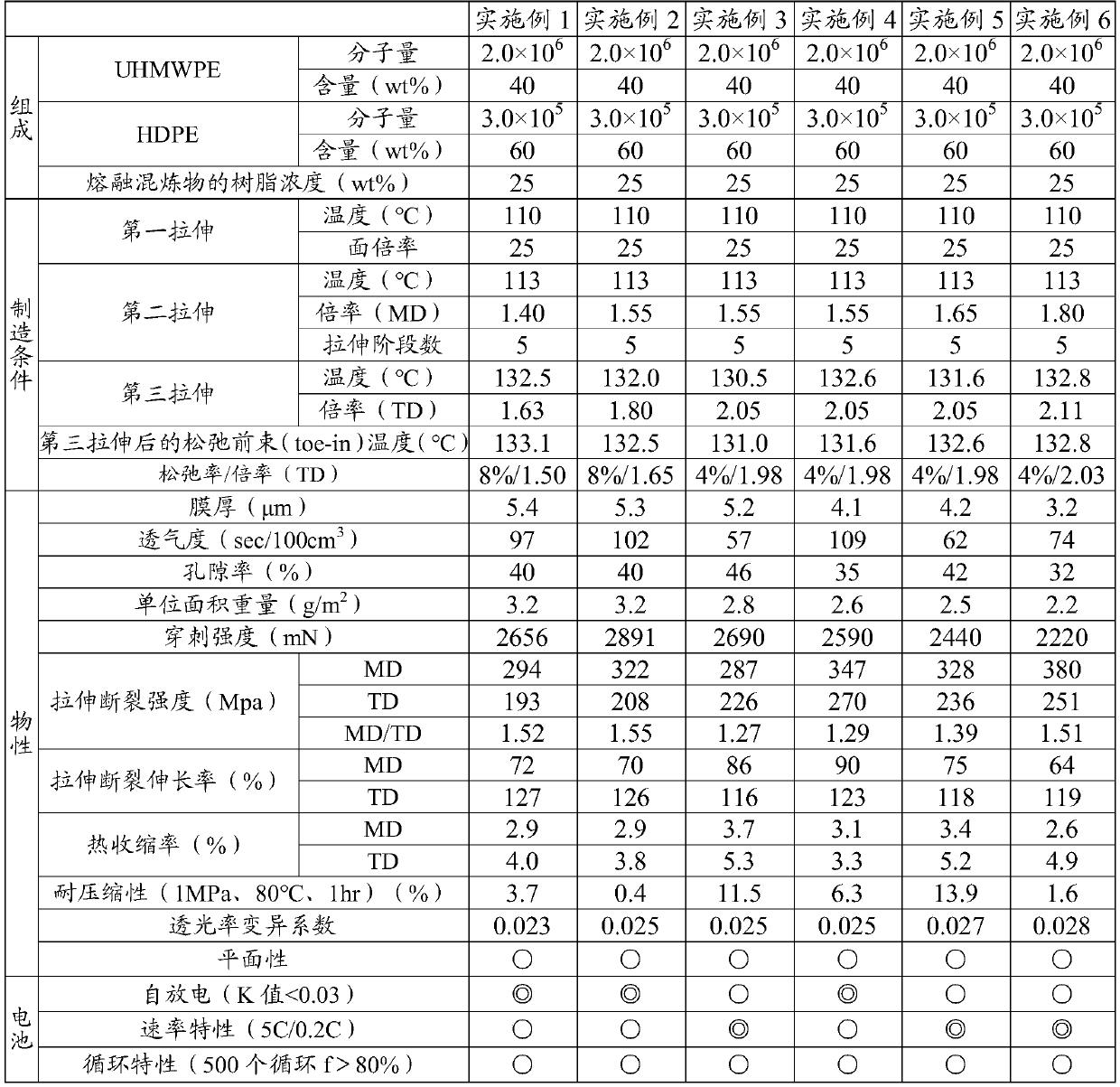

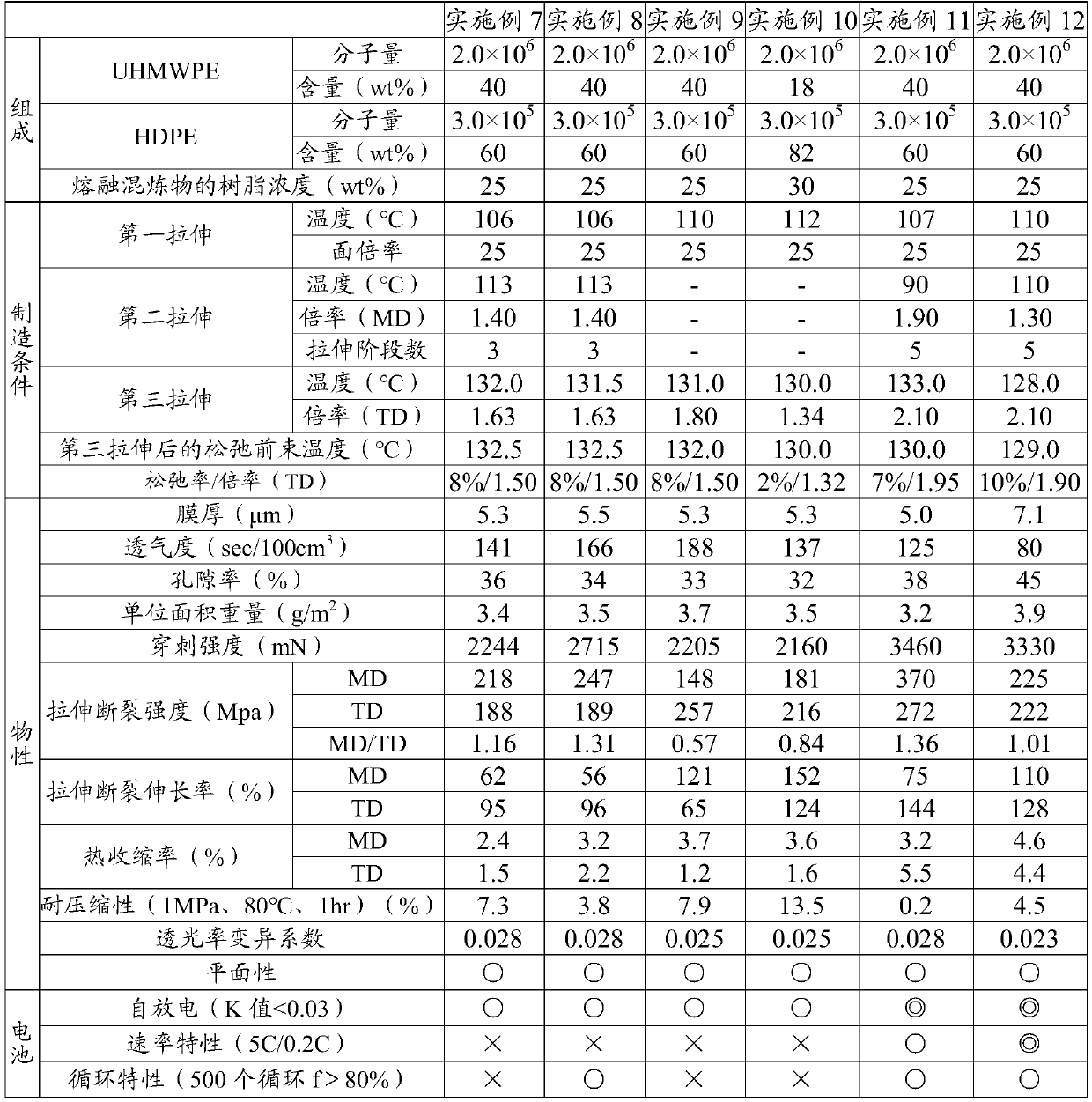

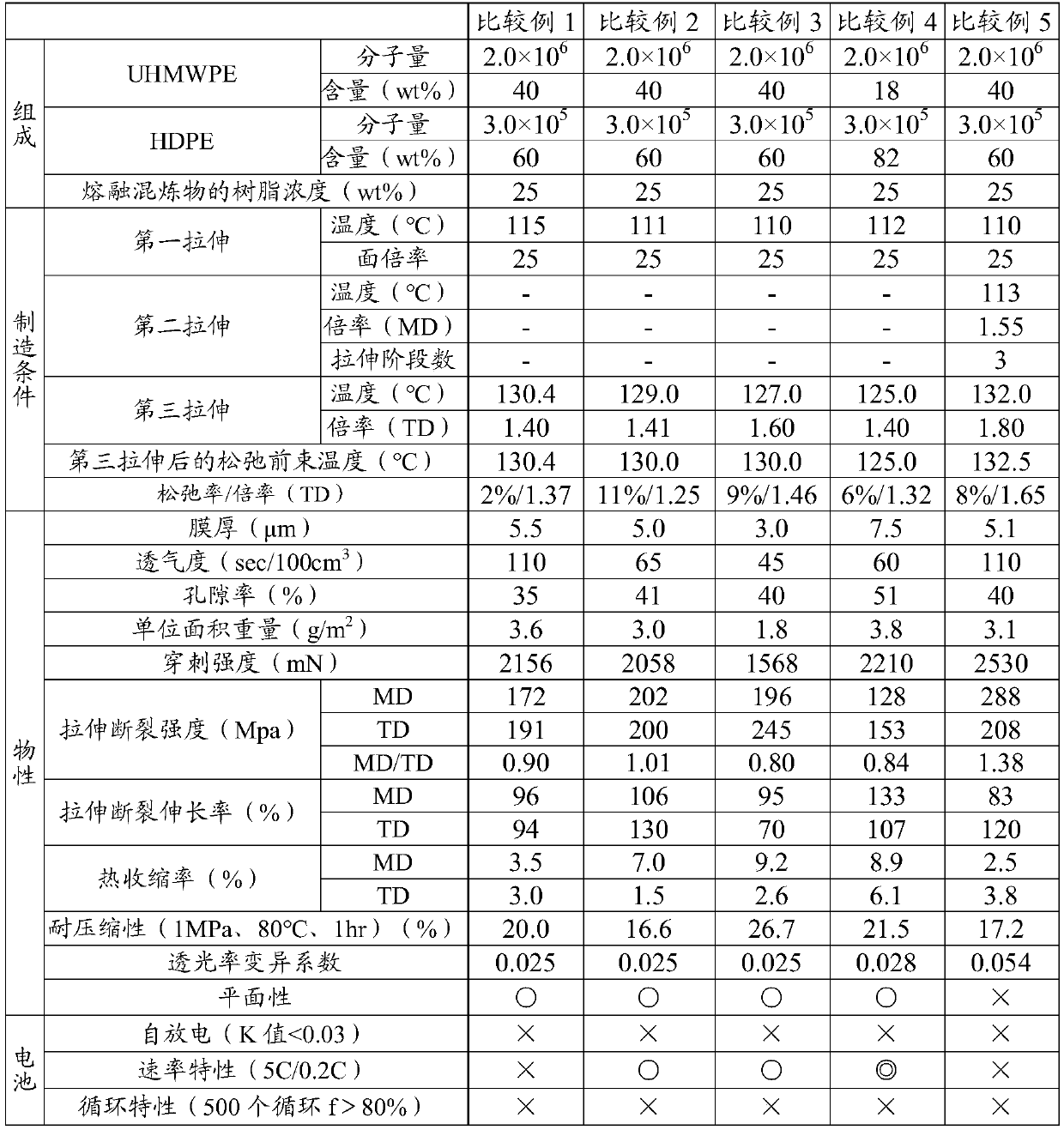

[0173] A polyolefin solution was prepared by melt-kneading the polyolefin resin and the liquid paraffin with the compositions shown in Tables 1 and 2 using a twin-screw extruder. The polyolefin solution was supplied to a T-die from a twin-screw extruder and extruded. The extruded body was cooled while being pulled with a cooling roll to form a gel-like sheet. Simultaneous biaxial stretching or sequential biaxial stretching (first stretching) by a tenter stretching machine at a temperature of 106° C. or higher and 112° C. or lower in both the MD and TD directions of the gel-like sheet is carried out by 5 times. . The stretched gel-like sheet was immersed in a dichloromethane bath, and the liquid paraffin was removed, followed by drying to obtain a dry film. The dry film is stretched 1.40 times or more and 1.90 times or less in the MD direction at a temperature of 90° C. or more and 113° C. or less by a roll stretching method using a batch stretching machine (second stretching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com