Magnetic rubber seal composite material with high pressure resistance and preparation method of magnetic rubber seal composite material

A magnetic rubber and composite material technology, applied in the field of functional magnetic sealing composite materials, can solve the problems of difficulty in meeting high pressure change, not involving pressure change performance, and magnetic seals that cannot meet the needs of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

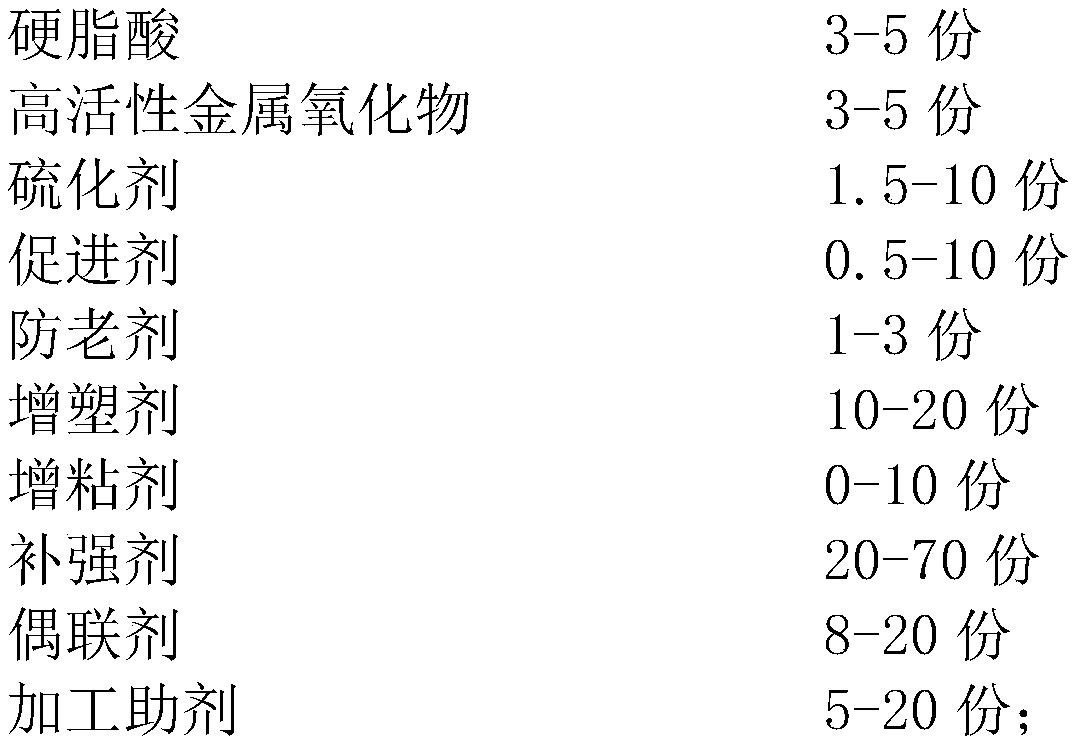

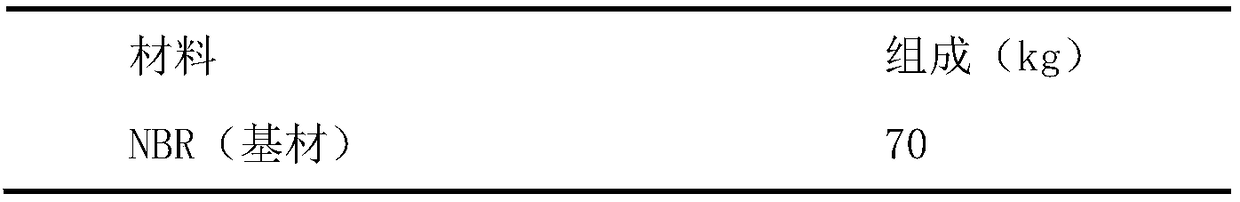

[0027] A high pressure change resistant magnetic rubber seal composite material, the main components of the composite material are as follows:

[0028]

[0029]

[0030] Processing method I is:

[0031] Prepare each raw material according to the formula, set the starting temperature of banburying to 50-60°C, and the speed to 40-60r / min. First, add stearic acid, anti-aging agent, reinforcing agent, processing aid and 1 / 3 of the formula amount of magnetic powder into the internal mixer. After mixing evenly, add nitrile rubber and mix for 2-4 minutes, then add neoprene rubber for internal mixing 2 -4min, then add tackifier, plasticizer and 2 / 3 of the formula amount of magnetic powder and coupling agent, knead for 5-8min to remove glue, the temperature of glue removal should be less than 140℃; After rolling, add highly active metal oxides, vulcanizing agents and accelerators to prepare the rubber mixture; after the rubber mixture is placed for 12-24 hours, it will be vulcan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com