Fiber-reinforced rubber elastomer composite material and preparation method thereof

A rubber elastic body and composite material technology, applied in the field of composite materials, can solve problems such as high viscosity, fiber interruption, and limited material compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

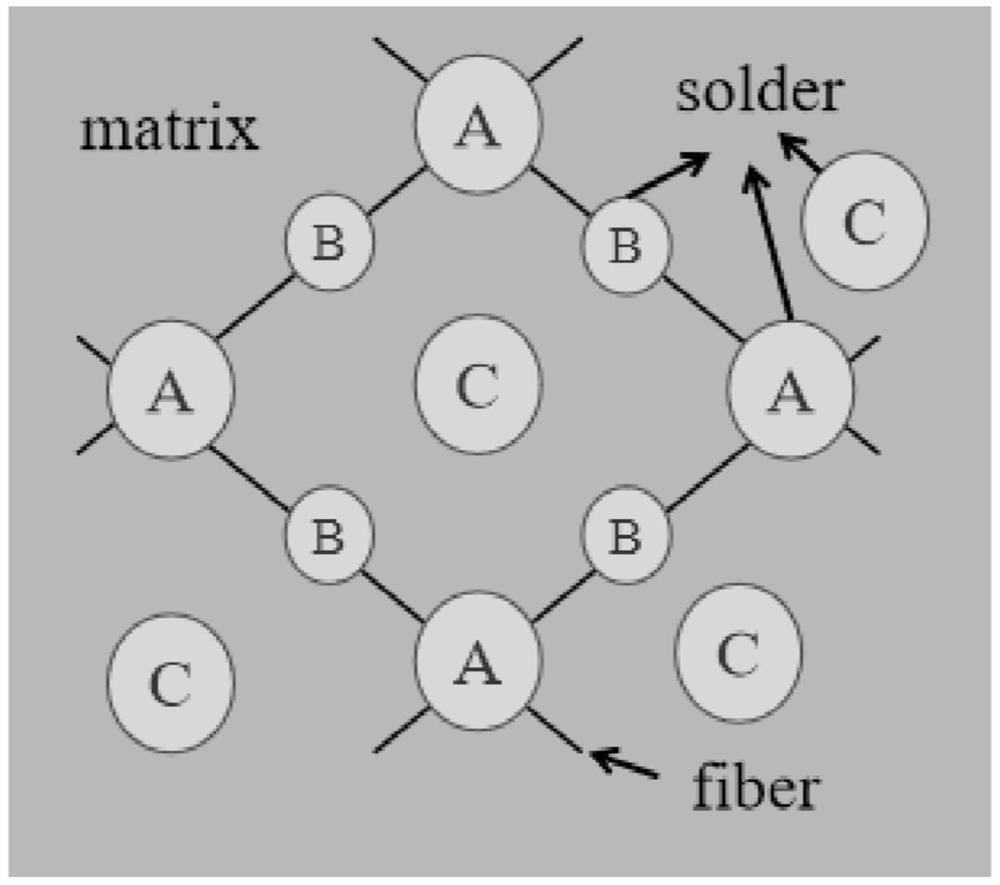

[0046] The preparation method of the thermosetting solder comprises the following steps: mixing a thermosetting resin, a curing agent and an accelerator, and mixing them uniformly with a stirrer to obtain the thermosetting solder. The viscosity of the thermosetting solder can be adjusted by means of constant temperature heating (less than 90° C.). The longer the constant temperature time is, the greater the viscosity will be (after the constant temperature time is over, the temperature will be cooled by an ice-water bath immediately).

[0047] The rubber matrix is a vulcanized thermosetting rubber, and a vulcanizing agent needs to be added during vulcanization. The mass ratio of the vulcanizing agent to the thermosetting rubber is 0.1-5%, preferably 1%, 3%, or 5%. In addition, the rubber matrix may be liquid or solid, with a viscosity of 0.1-100000 Pa.s, preferably 1-2000 Pa.s.

[0048] Described thermosetting rubber is conventional rubber, comprises solid rubber and liquid ...

Embodiment 1

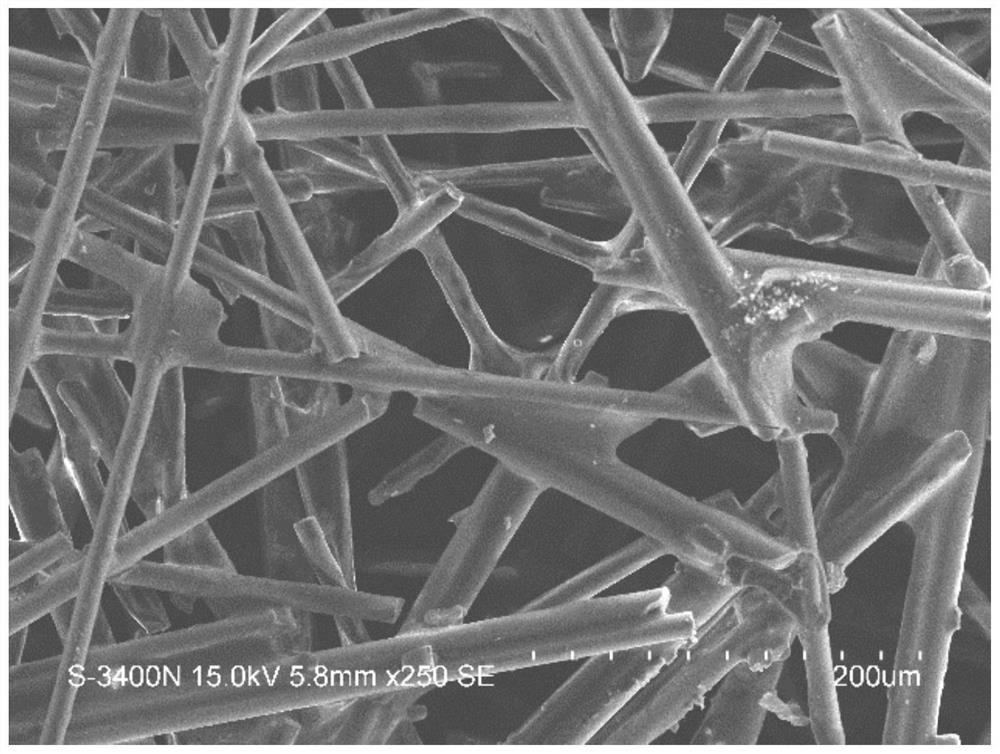

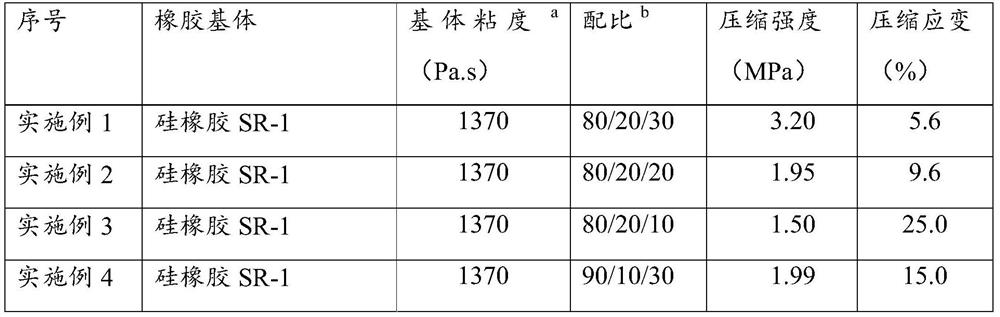

[0062] Vinyl silicone rubber SR-1 (viscosity of 50rad / s at room temperature is 1370Pa.s), vulcanizing agent dicumyl peroxide (content is 1% of the quality of silicone rubber) and glass fiber GF-KH560 (surface ring Oxygen group) into the internal mixer, blending at room temperature for 1min, adding epoxy resin EP (EP consists of E-51 resin (brand YD128) and curing agent methyl hexahydrophthalic anhydride, accelerator 2,4,6 -Tris(dimethylaminomethyl)phenol composition, the mass ratio of E-51 resin, curing agent methyl hexahydrophthalic anhydride, accelerator 2,4,6-tris(dimethylaminomethyl)phenol is 100: 70:5.), after continuing to blend for 10 minutes, take out the sample. Firstly, it is cured at a temperature of 100°C for 30 minutes; then it is vulcanized at a temperature of 150°C for 30 minutes, and two-step compression molding is performed to obtain a fiber-reinforced rubber elastomer composite material. The mass ratio of SR-1, epoxy resin EP and GF-KH560 is 80 / 20 / 30. The v...

Embodiment 2

[0064] The mass ratio of SR-1, EP and GF-KH560 is 80 / 20 / 20, and others are the same as in Example 1. The maximum compressive strength of the obtained fiber-reinforced rubber-elastomer composite is 1.95MPa, and the corresponding compressive strain is 9.6%, specifically The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Maximum compressive strength | aaaaa | aaaaa |

| Maximum compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com