Patents

Literature

30results about How to "Improve compression resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Microporous polyolefin film and process for producing the same

ActiveCN101155861AImprove breathabilityHigh mechanical strengthSemi-permeable membranesMembranesPolyolefinPolymer science

The microporous polyolefin film produced by drawing a gel molding containing a polyolefin and a solvent for film formation in at least a uniaxial direction, performing thermofixing treatment, removing the solvent for film formation and once more drawing the molding in at least a uniaxial direction has large pore diameter and excels in air permeability, mechanical strength and compression resistance.

Owner:TORAY IND INC

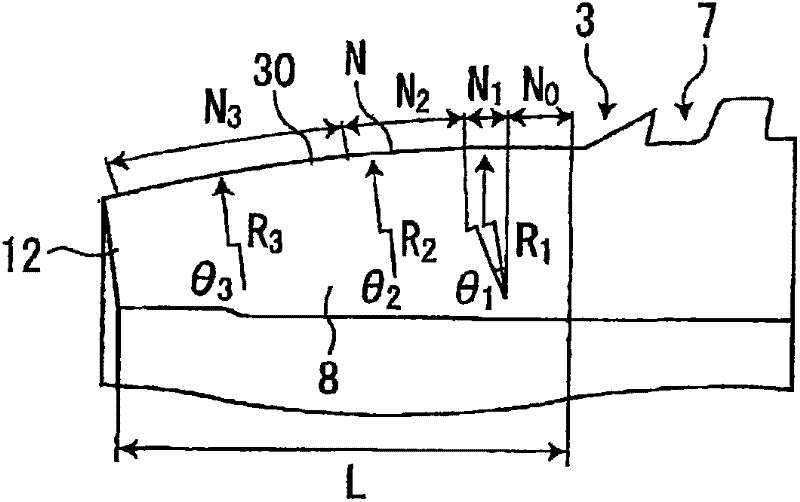

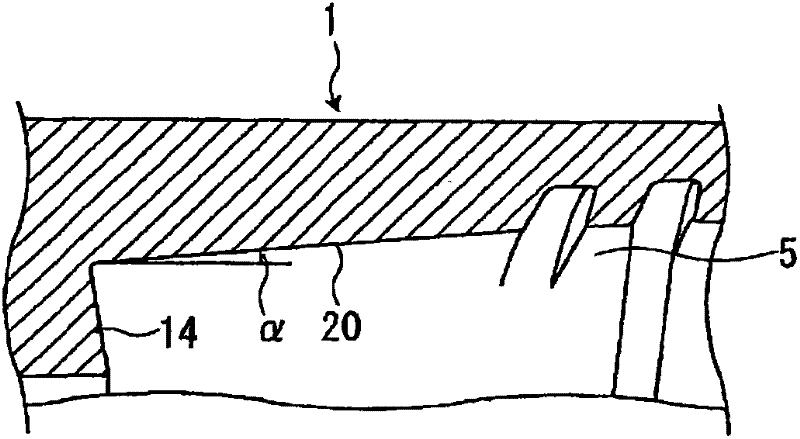

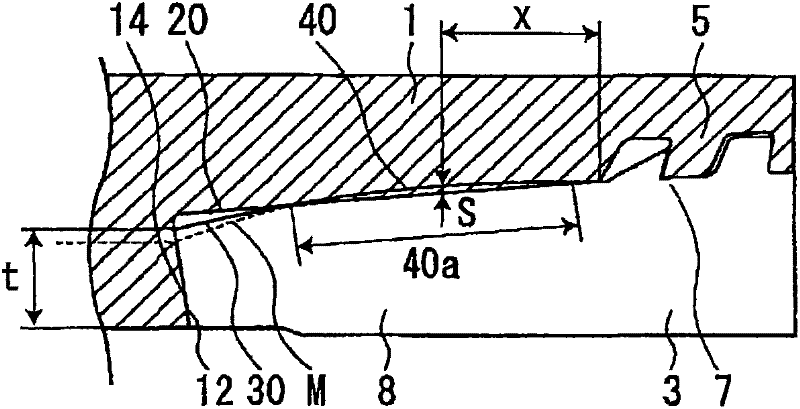

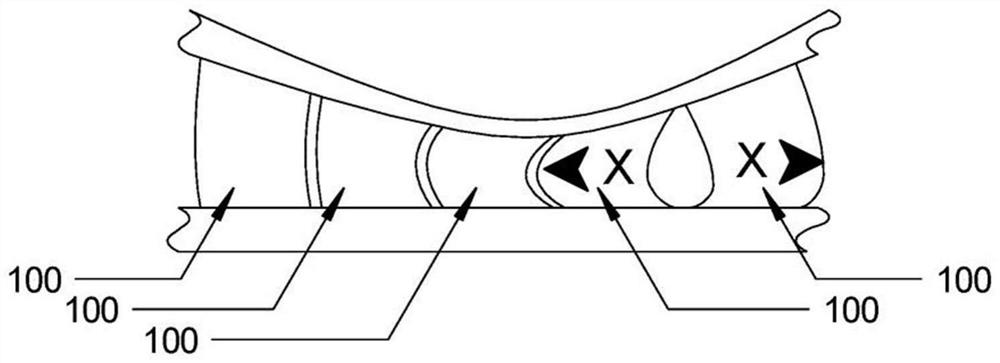

Pipe screw coupling

ActiveCN102313085AImprove sealingImprove compression resistanceDrilling rodsDrilling casingsCurve shapeCoupling

Disclosed is a pipe screw coupling that has increased sealing properties, compression resistance, and galling resistance. Specifically, the pin nose outer peripheral surface (30) forms a convex curve on the outside thereof in a cross section in the axial direction. Said convex curve has a curved shape wherein a compound-R curve (N) comprising a plurality of outwardly convex arcs that are connected in sequence and that have radii of curvature (R) that differ from each other at the generating line of a cylindrical section that is adjacent to a male screw section (5) is such that the radii of curvature (R) of the arcs increase with distance from the male screw section (5) and the line tangent to the connection point of an arc is the same as that of the arc connected to. The inner peripheral surface relative to the pin nose (30) of a box member (1) has a tapered surface (20) that interferes with the pin nose outer peripheral surface (30) when connecting with the pin member (3).

Owner:JFE STEEL CORP

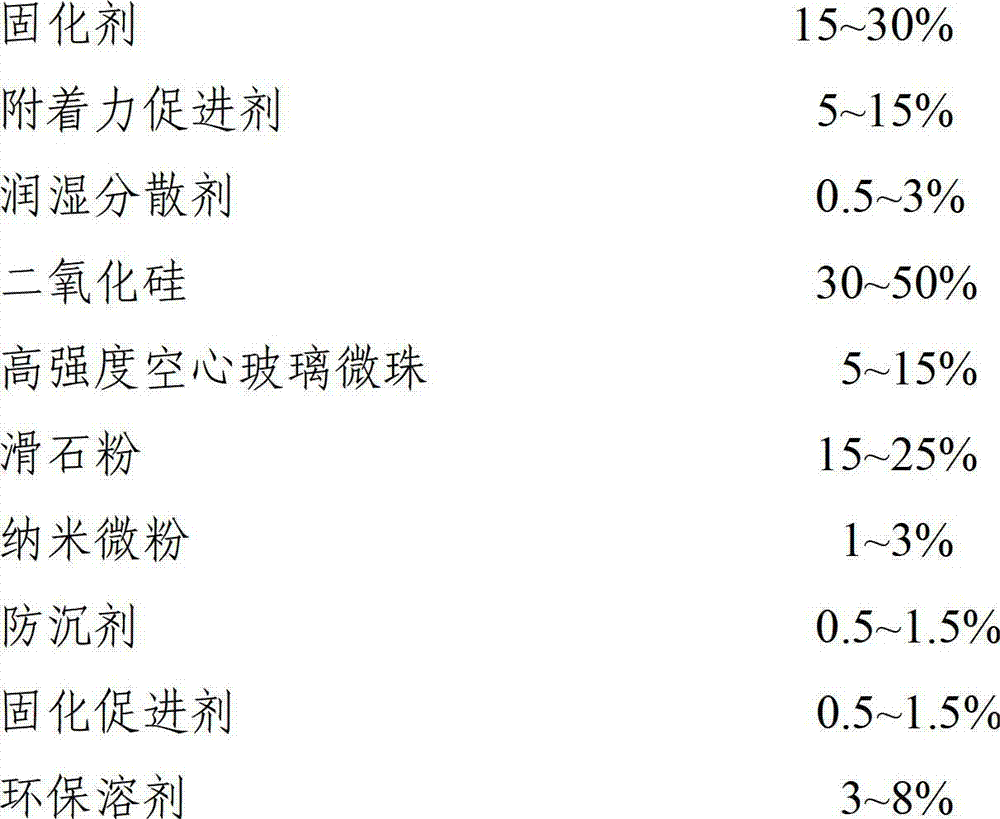

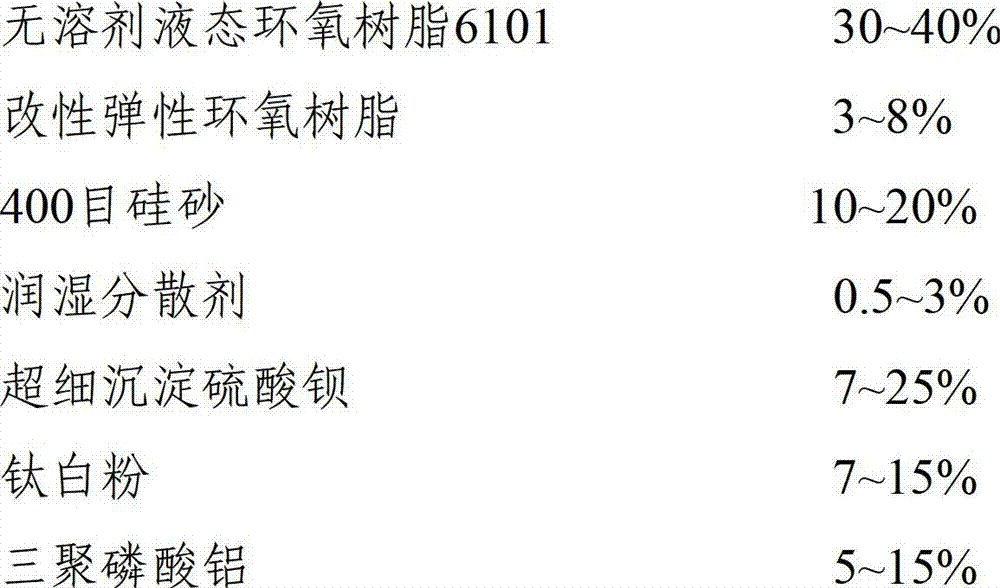

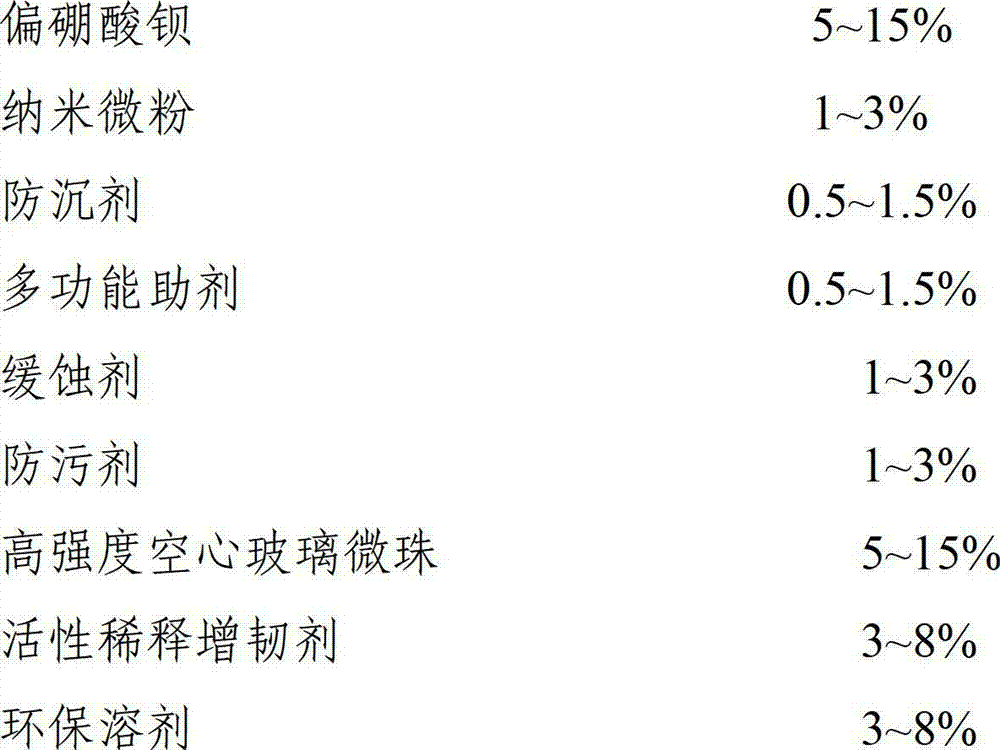

High-performance priming and finishing combined paint with corrosion inhibition, pollution prevention and heavy corrosion protection functions

ActiveCN103045048AAvoid bottom, middleAvoid the problem of difficult topcoat matchingAntifouling/underwater paintsPaints with biocidesEpoxySolvent free

The invention discloses a high-performance priming and finishing combined paint with corrosion inhibition, pollution prevention and heavy corrosion protection functions. The paint comprises two components: a component A includes a curing agent, an adhesion promoter, a wetting dispersant, silicon dioxide, hollow glass beads, talcum powder, nano micro powder, an anti-settling agent, a curing accelerator and an environment-friendly solvent; and a component B includes solvent-free liquid epoxy resin, modified elastic epoxy resin, silica sand, a wetting dispersant, superfine precipitated barium sulfate, titanium dioxide, aluminum triphosphate, barium metaborate, nano micro powder, an anti-settling agent, multi-functional auxiliaries, a corrosion inhibitor, an anti-fouling agent, high-strength hollow glass beads and an environment-friendly solvent. By aid of reasonable allocation of the component concentration, the paint has excellent adhesive force, durability, abrasion resistance and impact resistance, and excellent salt water resistance, oil resistance, alkali resistance and a certain degree of acid resistance; and the solid content is high, and the construction is convenient.

Owner:江阴市天邦涂料股份有限公司

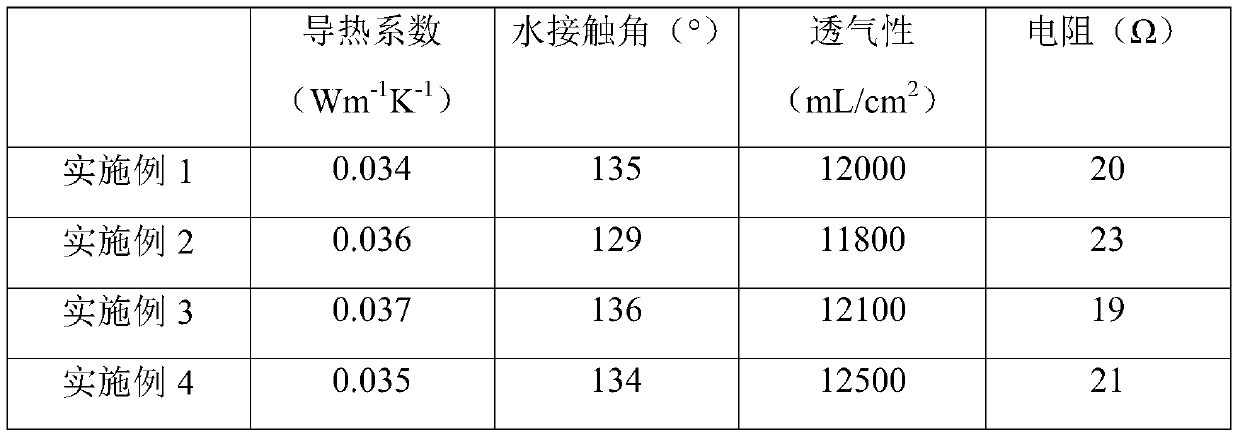

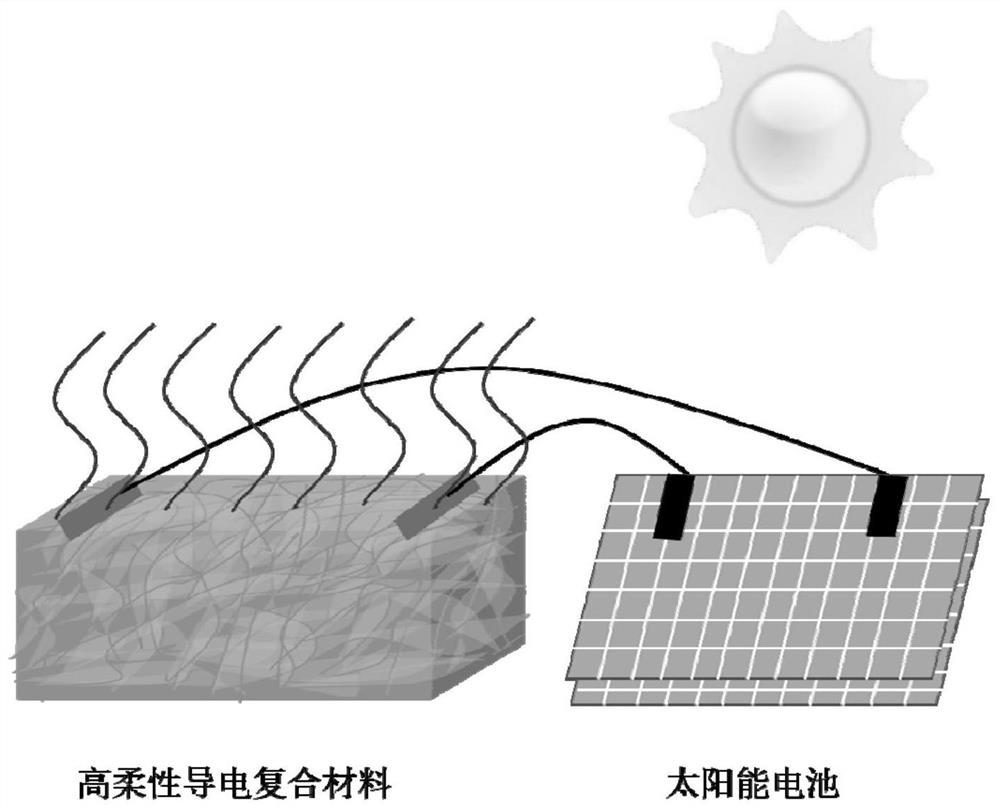

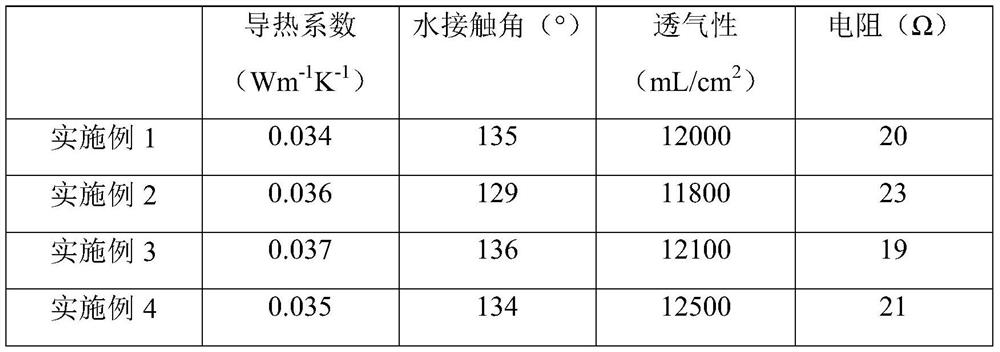

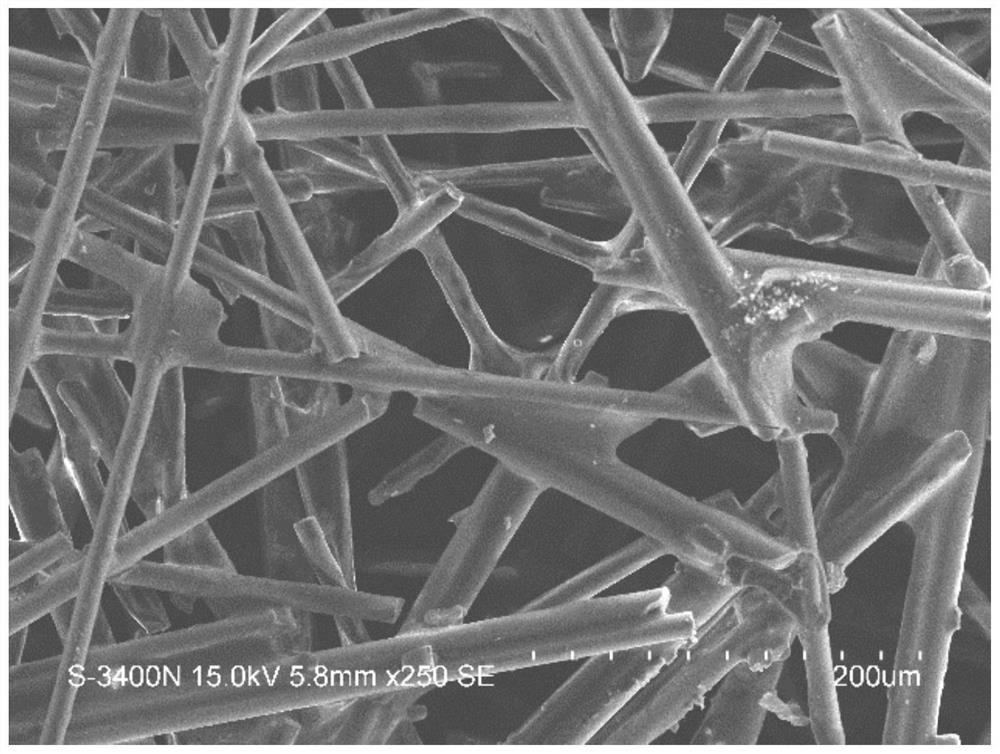

Bacterial cellulose/polypyrrole/polyurethane flexible multifunctional conductive composite material and preparation method thereof

ActiveCN110951109AImprove compression resistanceImprove flexibilityElectric heatingPolymer sciencePolypyrrole

The invention relates to a bacterial cellulose / polypyrrole / polyurethane flexible multifunctional conductive composite material and a preparation method thereof. The composite material is prepared by taking a bacterial cellulose material crosslinked by a silane coupling agent as a matrix material, and polypyrrole, coated polyurethane and a three-proofing finishing agent are grown in situ in sequence. When the obtained bacterial cellulose / polypyrrole / polyurethane porous composite material is used as an electric heating material to be used on clothes, the functions of electric heating, heat preservation, hydrophobicity and air permeability are achieved.

Owner:DONGHUA UNIV

EVA large hole composite foam material and preparation method

The invention discloses an EVA large hole composite foam material and a preparation method thereof. The composite foam material is prepared by mixing, granulation and foaming of materials, and the materials include: 40-60 mass parts of an ethylene-vinyl acetate copolymer, 10-20 mass parts of graphene modified isotactic polybutene, 10-15 mass parts of a polyolefin thermoplastic elastomer, 10-20 mass parts of a polyester elastomer, 0.4-0.8 mass part of an active agent, 0.7-1.5 mass parts of a cross-linking agent, 2.5-3.5 mass parts of a foaming agent and 0.1-0.3 mass part of an assistant. The mass content of vinyl acetate in the ethylene-vinyl acetate copolymer is 26%-40%. The preparation method of the EVA large hole composite foam material includes: weighing a certain amount of isotactic polybutene-1 for melting, adding 0.05%-0.2% by mass of graphene when the melting temperature of the isotactic polybutene-1 is 140-170DEG C, and mixing the two substances to obtain graphene modified isotactic polybutene. The large holes in the EVA large hole composite foam material has good foaming effect, the compression resistance and resilience are enhanced, and also the softness and wear resistance are also improved. The preparation method is simple and easy to operate.

Owner:ANTA CHINA

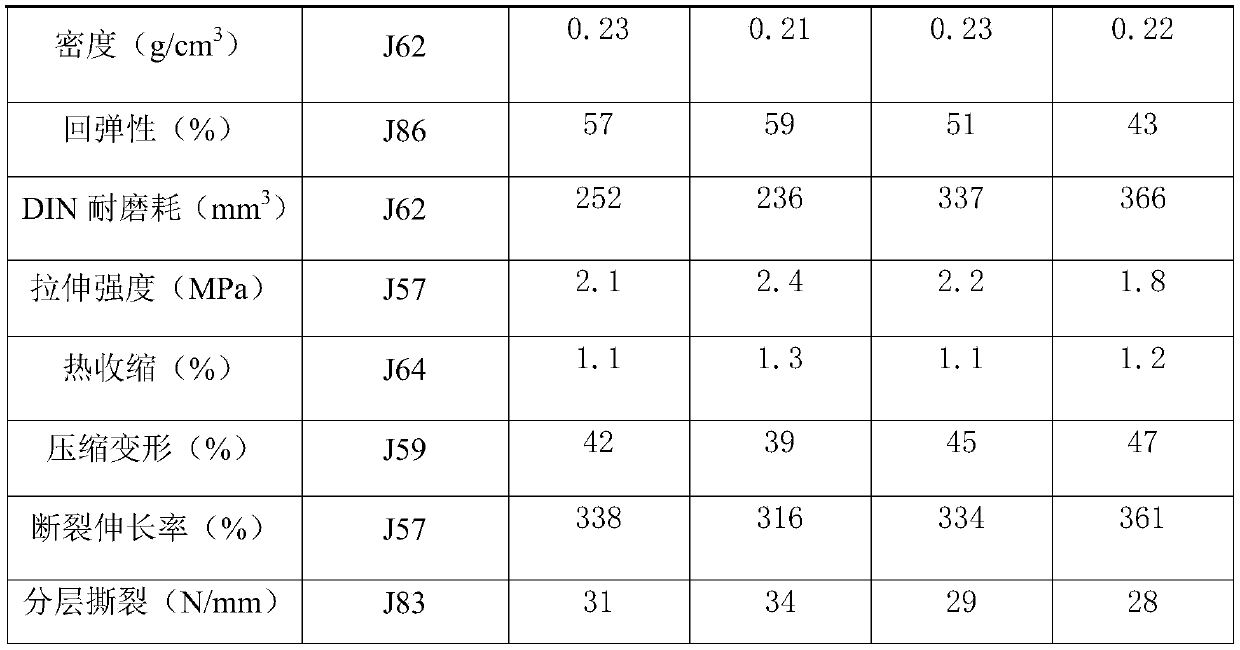

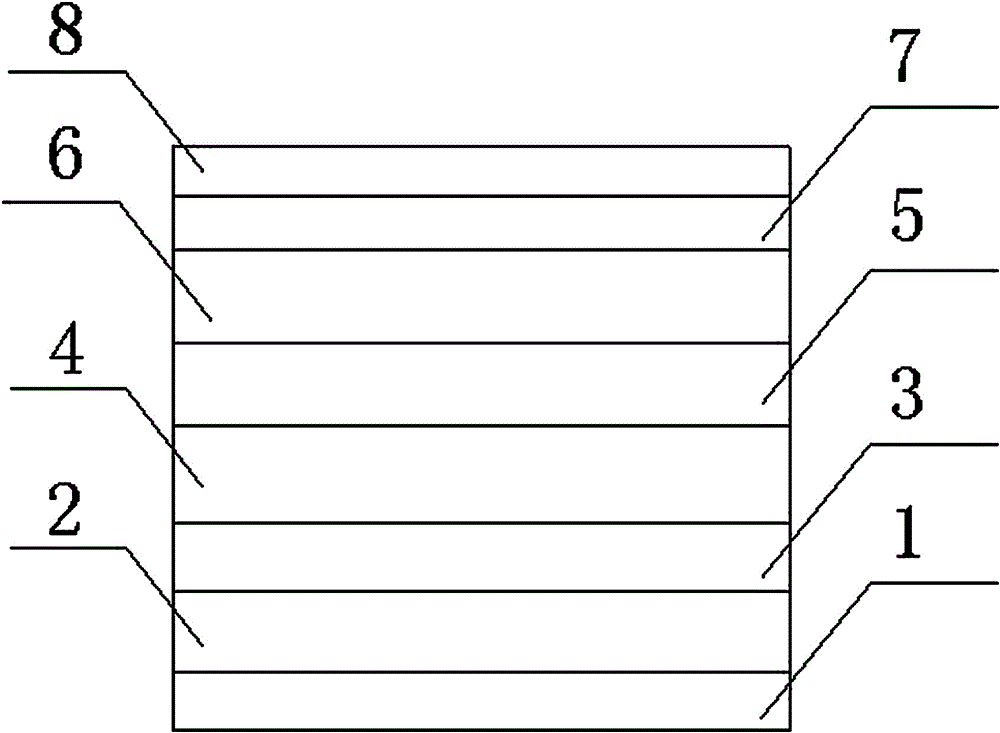

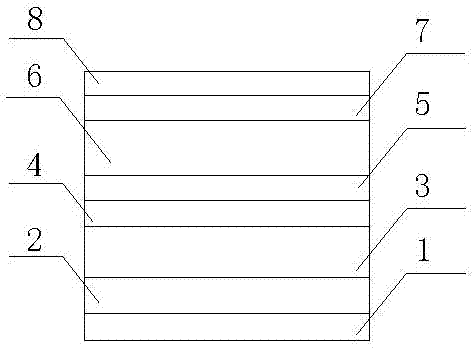

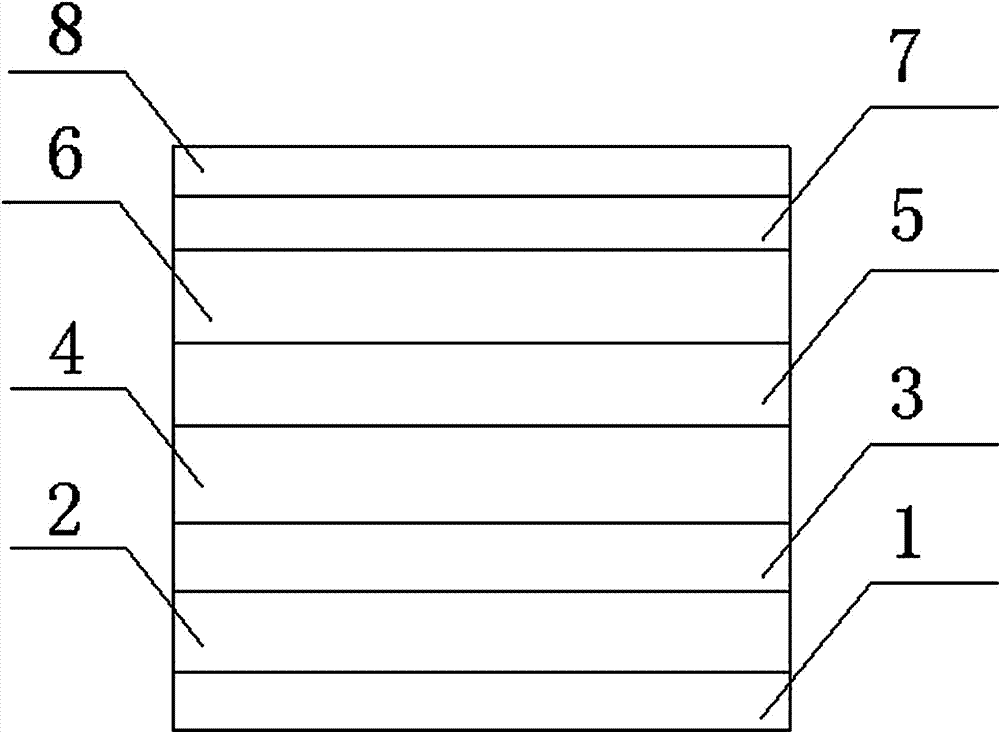

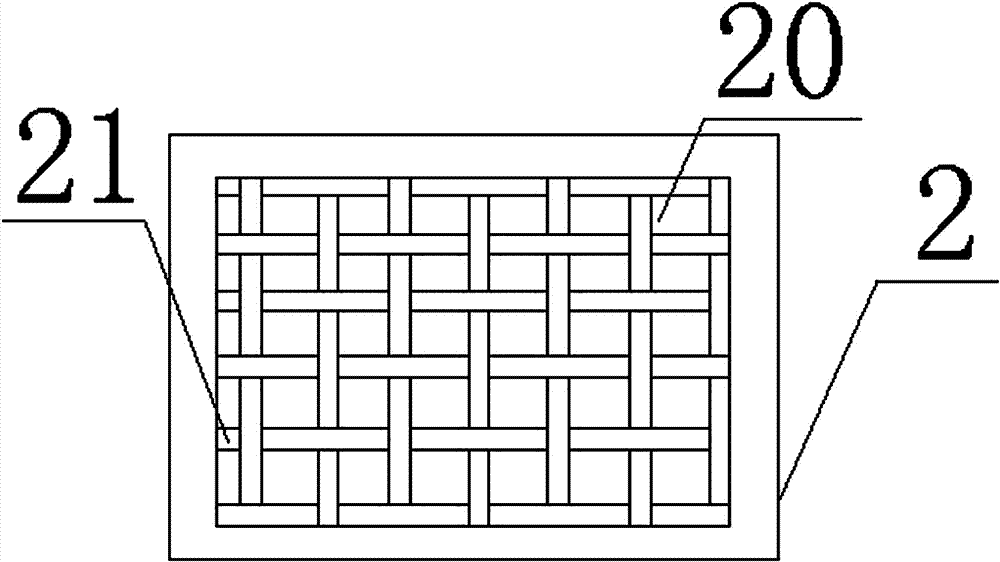

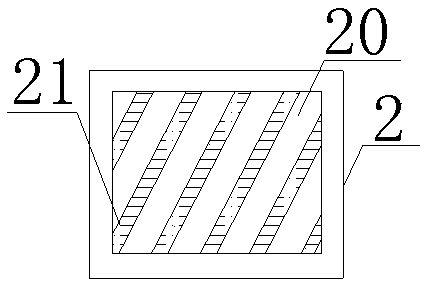

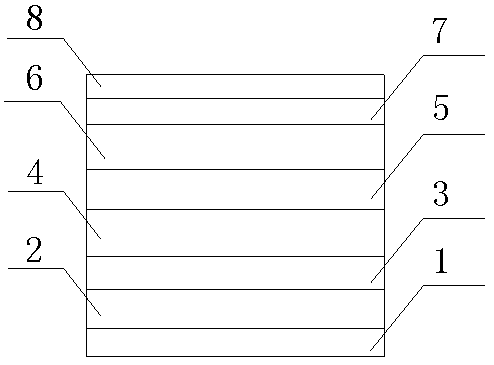

Heat insulation fireproof wallboard

ActiveCN106013594AImprove toughening effectImprovement and StrengthBuilding componentsFiber layerEngineering

The invention discloses a heat insulation fireproof wallboard which comprises a base layer, an inner fiber board layer attached to the base layer, a heat insulation layer attached to the inner fiber board layer, a vacuum layer attached to the heat insulation layer, a protective layer attached to the vacuum layer, an outer fiber layer attached to the protective layer, a waterproof layer attached to the outer fiber board, and a reflective layer attached to the waterproof layer. The heat insulation fireproof wallboard has the excellent fireproof performance, is extinguished right after being deviated from fire, and is high in toughness and strength and excellent in heat insulation effect.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

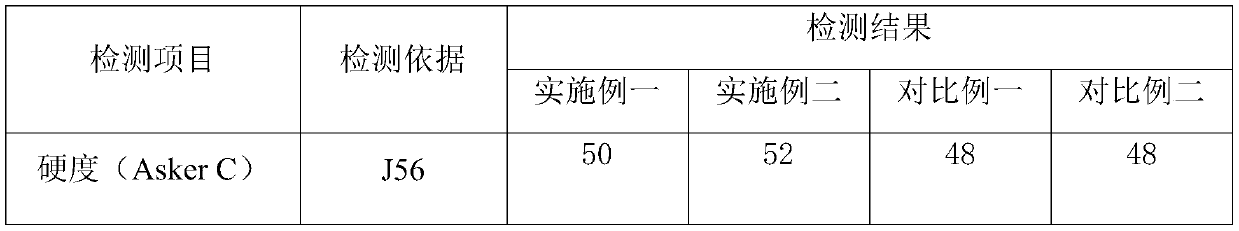

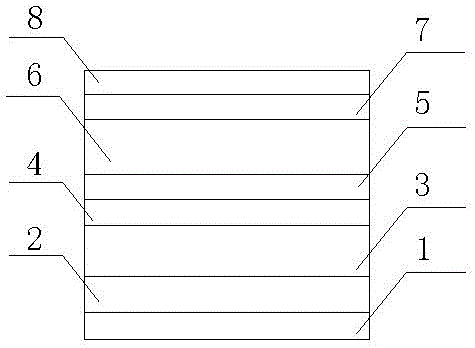

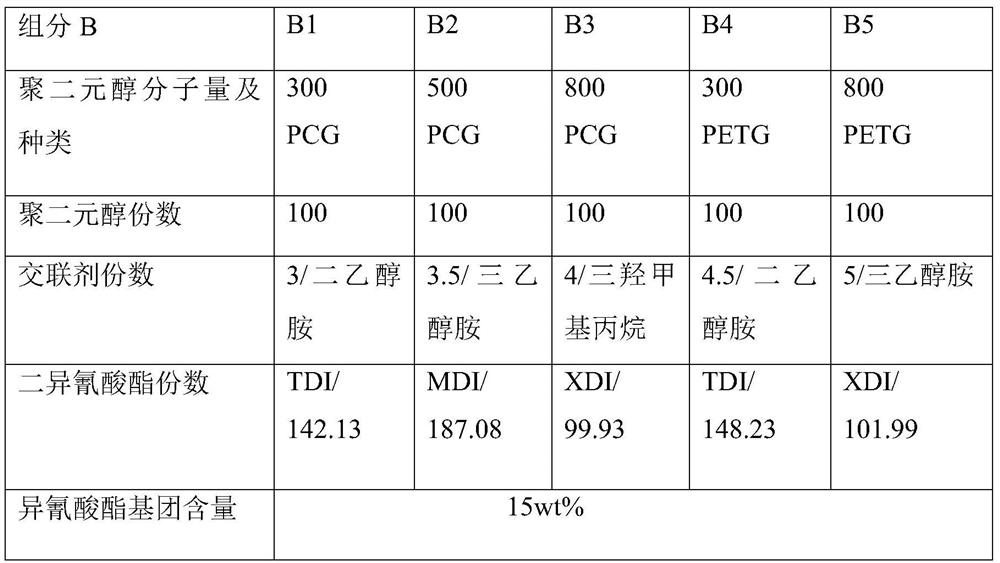

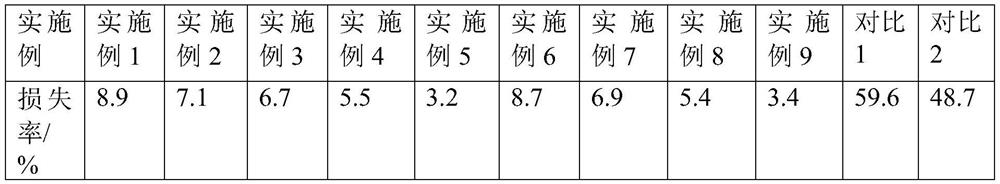

Compression-resistant polyurethane foam and preparation method thereof

ActiveCN113292764ADoes not change the macrostructureEasy to compressPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses compression-resistant polyurethane foam. The compression-resistant polyurethane foam comprises a component A and a component B, wherein the component A comprises polydihydric alcohol of which the molecular chain does not contain F, O and N elements, and expanded microspheres, a low-boiling-point foaming agent, a catalyst and a surfactant; the component B comprises diisocyanate, a chain extender, a cross-linking agent and polydihydric alcohol, wherein the diisocyanate is excessive; the component A and the component B are mixed and then coated on the surface of a high polymer material or metal material film, and the polyurethane foam is obtained after curing molding. The invention also discloses a preparation method of the compression-resistant polyurethane foam. The final polyurethane molecular blocks are arranged in order, and the polyurethane foam has a three-stage compression-damping structure at a microscopic level so that the polyurethane foam has good compression resistance, has long service time under a compression condition, and can better adapt to a service environment and protect devices.

Owner:HUBEI XIANGYUAN NEW MATERIAL TECH INC

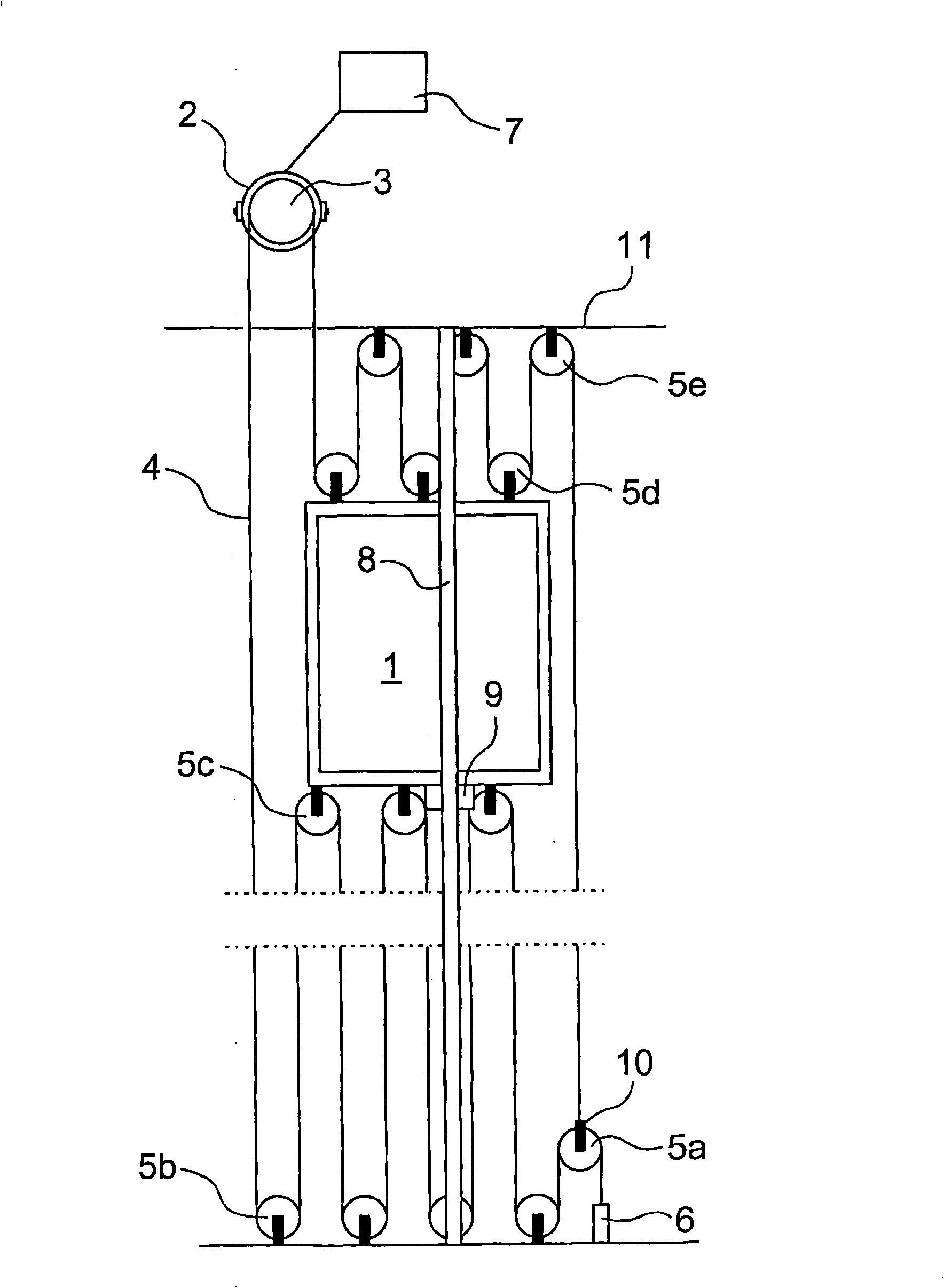

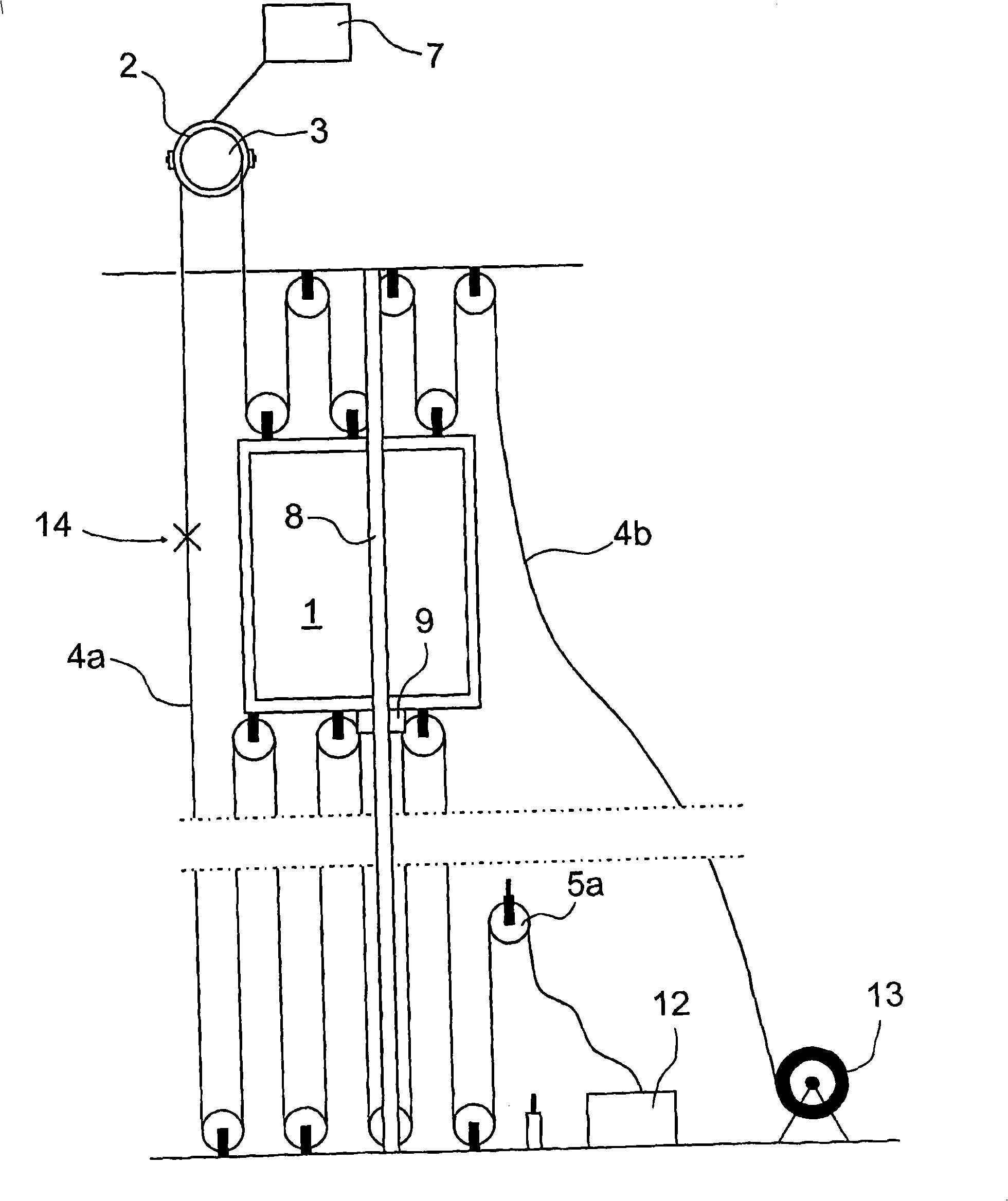

Elevator system

InactiveCN101309849AEasy to replaceSafe and quick replacementRopes and cables for vehicles/pulleyRope making machinesElevator systemEngineering

Owner:KONE CORP

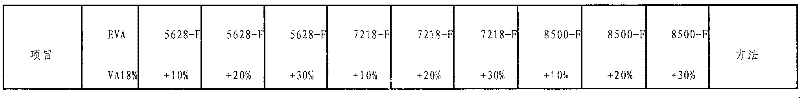

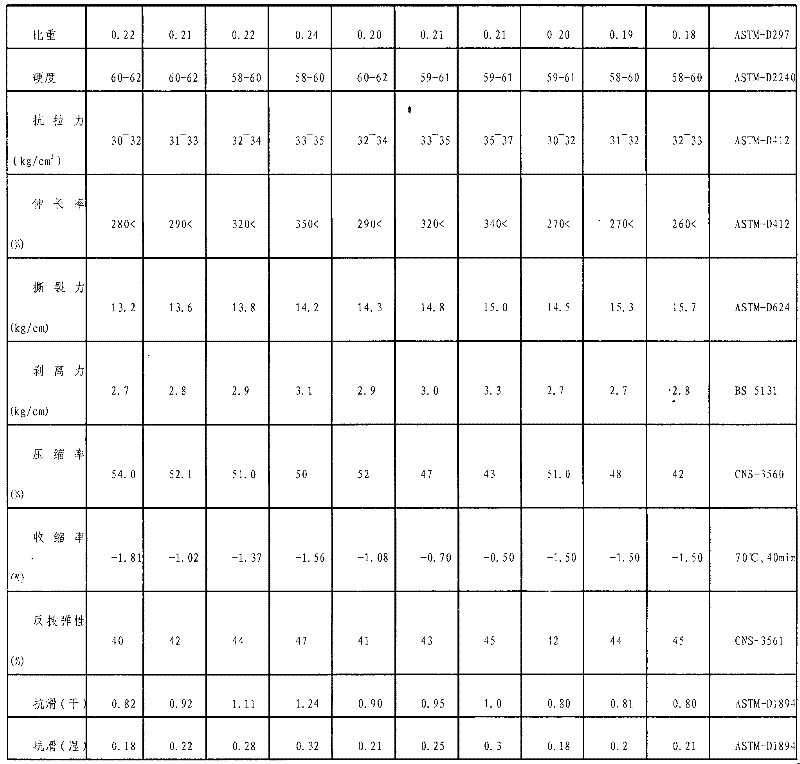

Application of SEBS (styrene-ethylene-butylene-styrene) in sports equipment preparation process as foaming modifier

InactiveCN102532581AImprove compatibilityGood dynamic viscoelasticityDynamic viscoelasticityRetrievability

The invention discloses application of an SEBS (styrene-ethylene-butylene-styrene) in a sports equipment preparation process as a foaming modifier. After being modified with an SEBS foaming material, EVA (ethylene-vinyl acetate) has better dynamic viscoelastic property and meets the testing requirement of human engineering; and the properties of EVA are improved in the aspects of flexibility, compressibility resistance, limited slip resistance, elasticity, material stretchability and the like. The SEBS foaming material has the characteristics of good elasticity, plasticity absent in a thermosetting material and rim leftover retrievability.

Owner:吴水莲

Elastic fireproof wallboard

ActiveCN106049786ALarge specific surface areaIncrease the areaCovering/liningsCeramicwareInsulation layerEngineering

The invention discloses an elastic fireproof wallboard which comprises a base layer, a frame layer, an adhesive layer, a plastering mortar layer, an insulation layer, a latex layer, a decorative coating and an abrasion-resistant layer. The base layer is covered by the frame layer. The frame layer is composed of a plurality of workpieces which are arranged in parallel or in a staggered mode and form filling cavities. The filling cavities are filled with filler. The frame layer is covered by the adhesive layer. The adhesive layer is covered by the plastering mortar layer. The plastering mortar layer is covered by the insulation layer. The insulation layer is covered by the latex layer. The upper surface of the latex layer is coated with the decorative coating made of decorative paint. The upper surface of the decorative coating is coated with the abrasion-resistant layer made of transparent abrasion-resistant paint.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

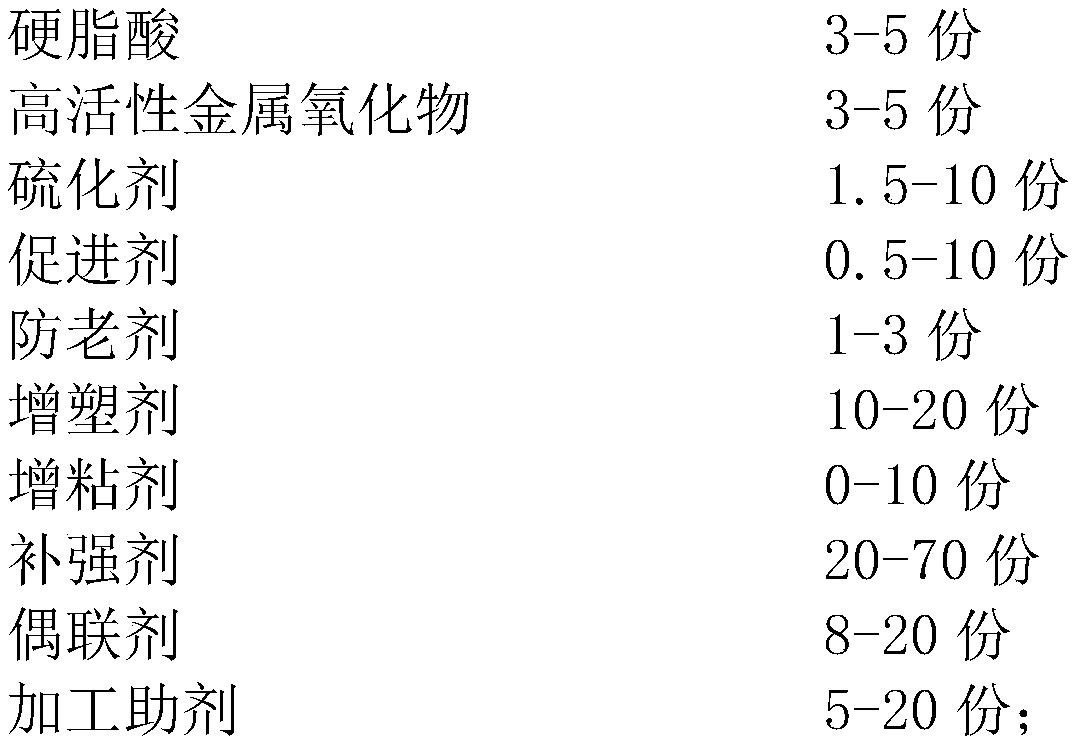

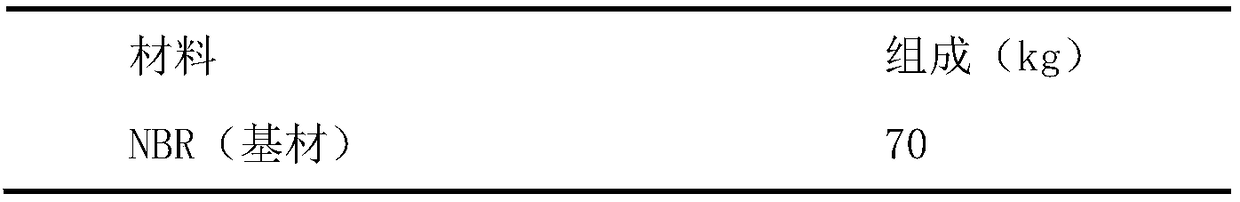

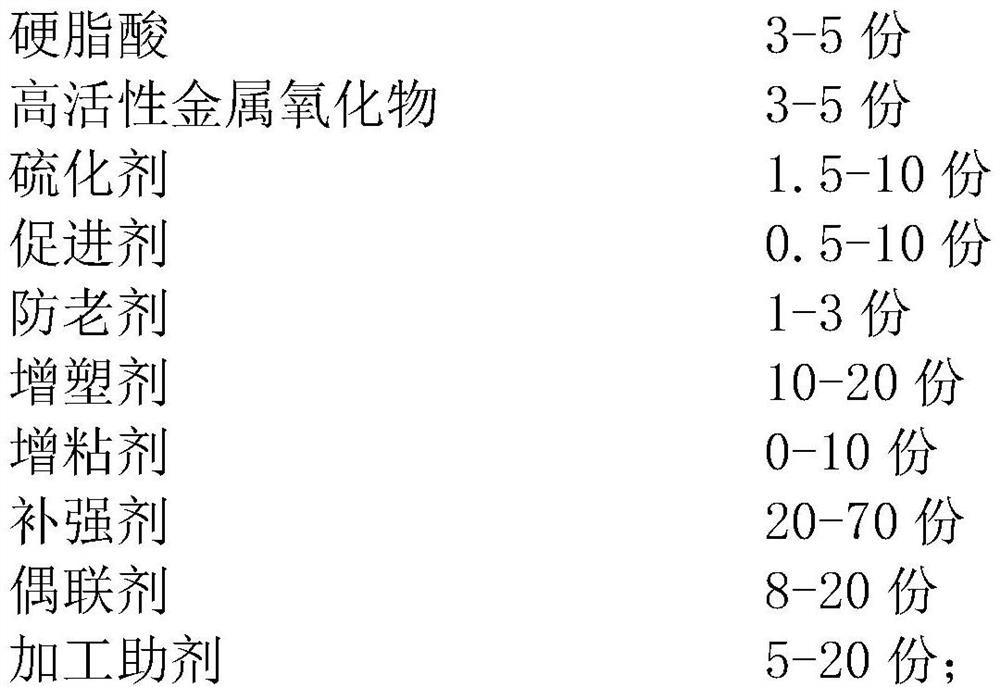

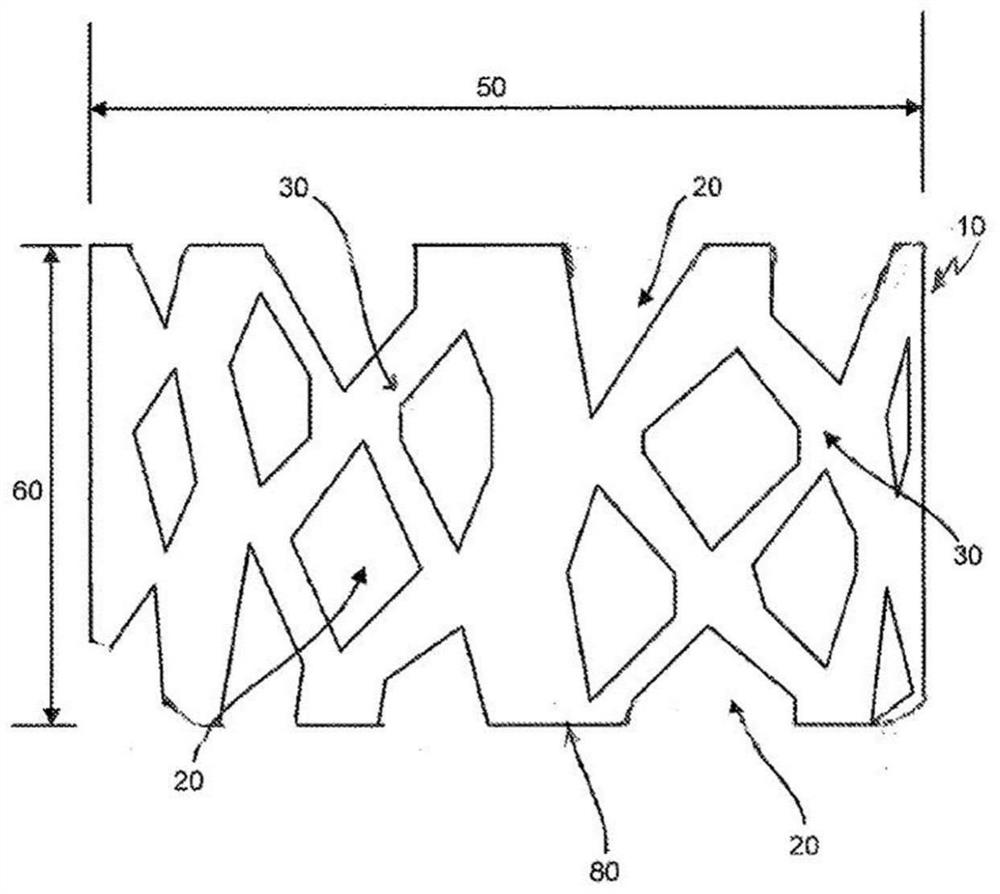

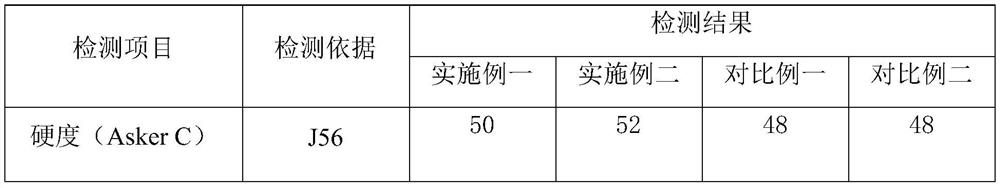

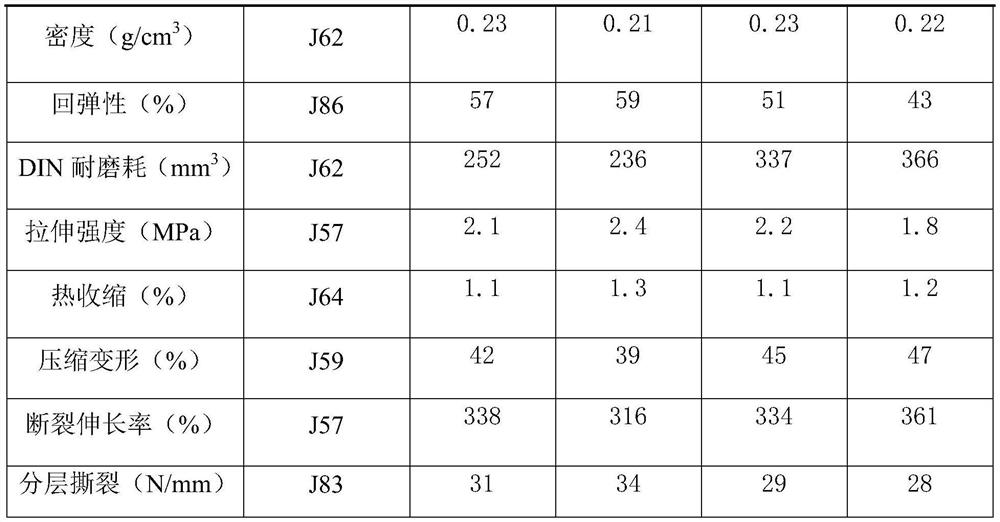

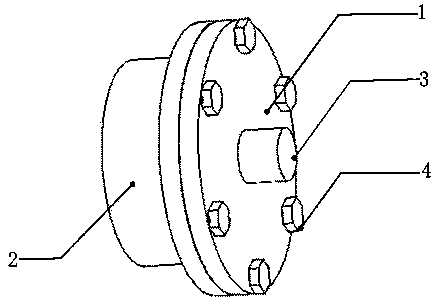

Magnetic rubber seal composite material with high pressure resistance and preparation method of magnetic rubber seal composite material

The invention relates to the field of functional magnetic seal composite materials, in particular to a magnetic rubber seal composite material with high pressure denaturation and a preparation methodof the magnetic rubber seal composite material. The magnetic rubber seal composite material is mainly characterized by forming by nitrile rubber, neoprene, magnetic powder and a reinforcement, vulcanization and protection system, mixing with an internal mixer and shaping and vulcanizing with a vulcanizing machine. The magnetic rubber seal composite material has the advantages of good dynamic sealing and static sealing and solvent resistance, high pressure denaturation, good thermal stability, magnetic stability and the like.

Owner:QINGDAO UNIV OF SCI & TECH +2

A kind of thermal insulation firewall board

ActiveCN106013594BGood fire resistance and heat resistanceImprove toughnessBuilding componentsInsulation layerEngineering

The invention discloses a heat insulation fireproof wallboard which comprises a base layer, an inner fiber board layer attached to the base layer, a heat insulation layer attached to the inner fiber board layer, a vacuum layer attached to the heat insulation layer, a protective layer attached to the vacuum layer, an outer fiber layer attached to the protective layer, a waterproof layer attached to the outer fiber board, and a reflective layer attached to the waterproof layer. The heat insulation fireproof wallboard has the excellent fireproof performance, is extinguished right after being deviated from fire, and is high in toughness and strength and excellent in heat insulation effect.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

Flame-retardant environment-friendly foamed plastic

The invention discloses a flame-retardant environment-friendly foamed plastic which comprises the following raw materials in parts by weight: 32-37 parts of ethylene-vinyl acetate (EVA) resin, 68-72 parts of polycaprolactone (PCL), 2.8-3.2 parts of soybean meal, 2.7-3.6 parts of wood fibers, 1.2-1.7 parts of a titanate coupling agent NDZ-TTS, 3-3.6 parts of sodium lactate, 13-17 parts of a foaming agent ADC, 8-12 parts of zinc oxide, 9-10 parts of citric acid, 11-14 parts of sodium hydrogen carbonate, 1.6-1.9 parts of diisononyl phthalate (DINP), 2.2-2.7 parts of epoxy octyl stearate, 23-28 parts of barite powder, 15-18 parts of augite powder, 7-11 parts of white carbon black, 5-9 parts of mica powder, 3-6 parts of ammonium polyphosphate, 5-8 parts of melamine sodium polyphosphate, 1.5-1.8 parts of 2,6-di-tert-butyl-4-methylphenol (BHT) and 1.3-1.6 parts of an antioxidant BLE.

Owner:NINGGUO NINGSHENG RUBBER PROD

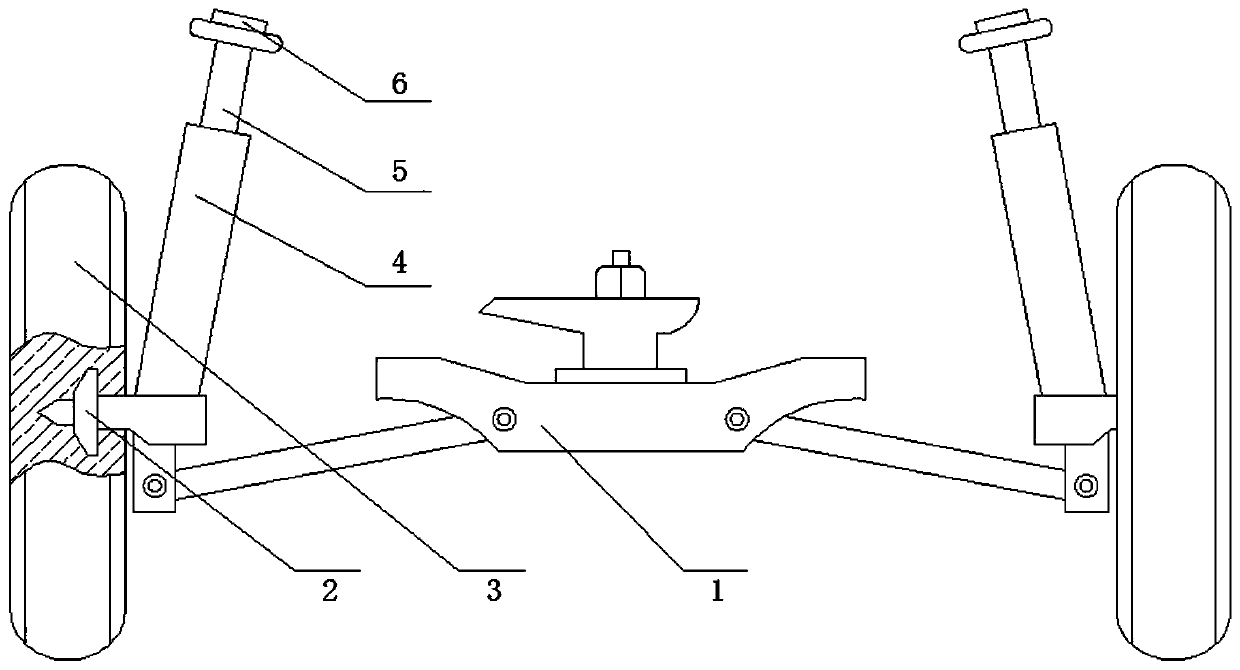

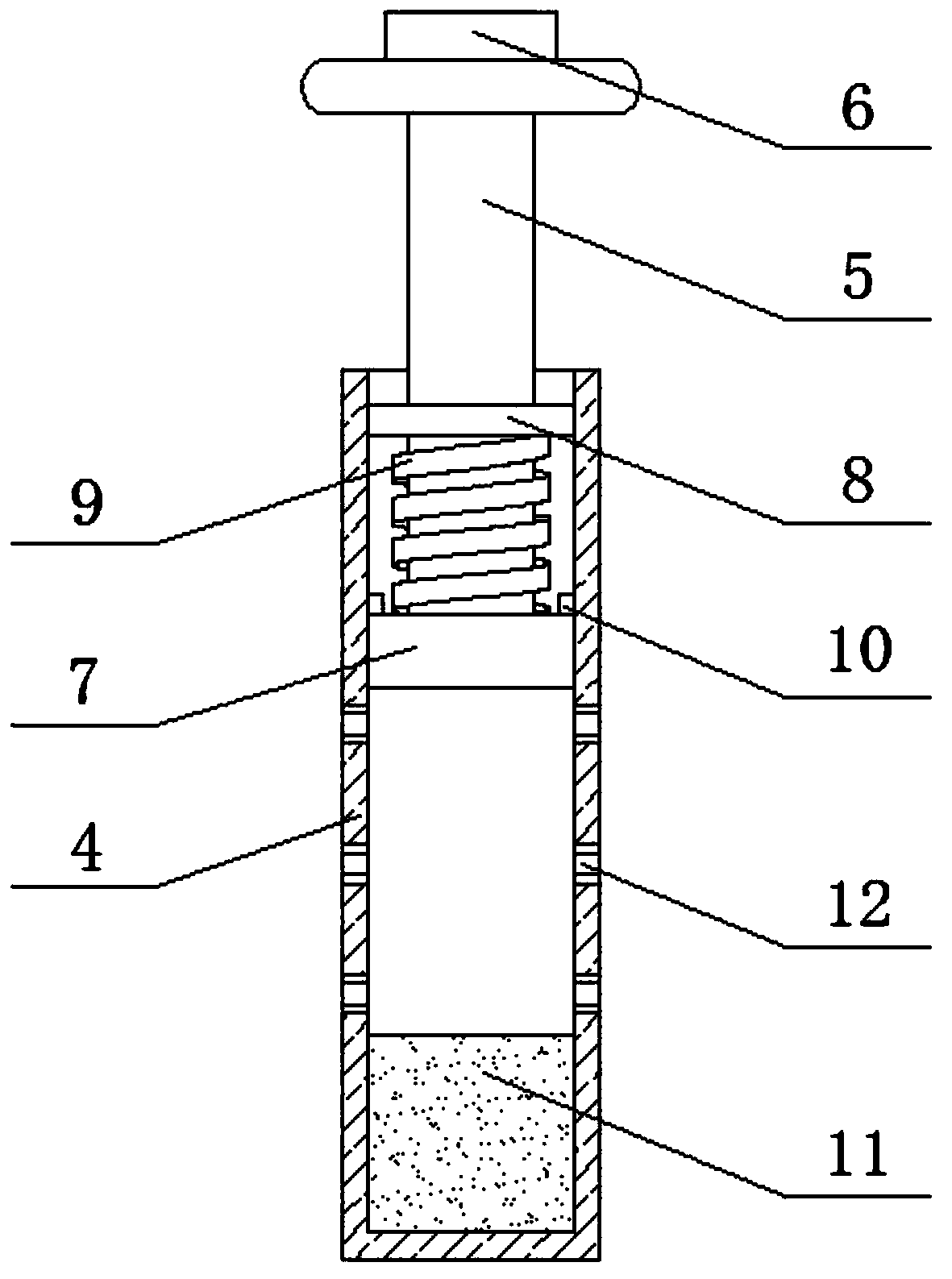

Novel micro-truck axle assembly

InactiveCN110293806AImprove shock absorptionIncrease diversityResilient suspensionsVehicle springsPistonTruck

The invention discloses a novel micro-truck axle assembly, and belongs to the field of axles. The novel micro-truck axle assembly comprises a horizontal swing arm, wherein steering knuckles are fixedly mounted at the ends of the horizontal swing arm, wheels are fixedly installed outside the steering knuckles, the top of the horizontal swing arm is fixedly connected with cylinders, a moving rod ismovably sleeved with each cylinder, an upper supporting end is fixedly installed at the top of each moving rod, a piston is fixedly installed at the bottom of each moving rod, and each moving rod is movably sleeved with a baffle. According to the novel micro-truck axle assembly, by arranging the cylinders, the moving rods, the pistons, rubber blocks and air holes, in the use process of the axle assembly, double force release and vibration absorption can be conducted by means of piston compressed air and elastic properties of the rubber blocks, as the number of the air holes gradually decreases, the compression resistance of the pistons gradually increases, the intensity of released force also increases, the vibration absorption effect can be improved, and the diversity of vibration absorption modes of the axle assembly is increased.

Owner:湖北银通专用汽车有限公司

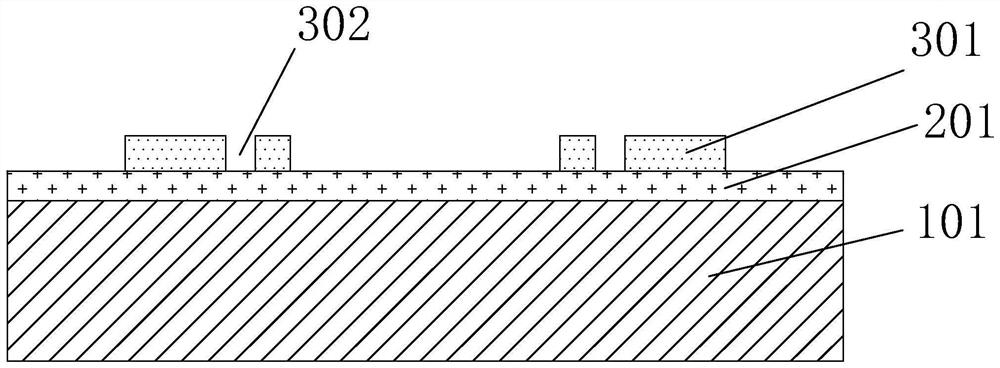

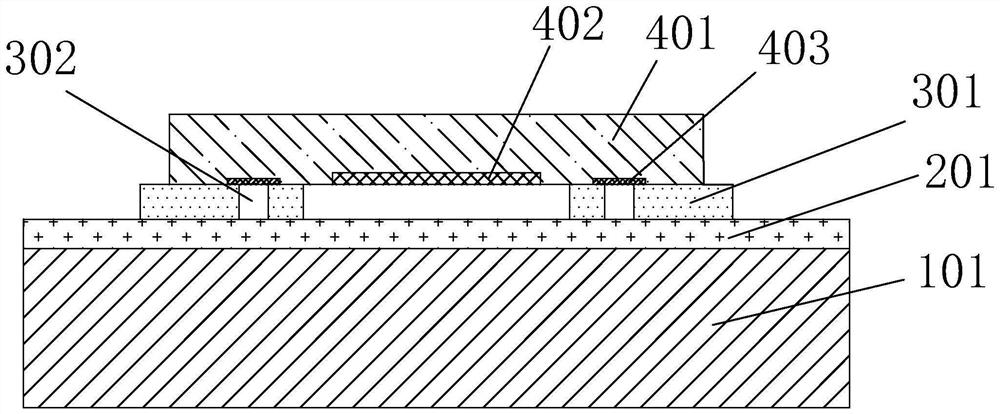

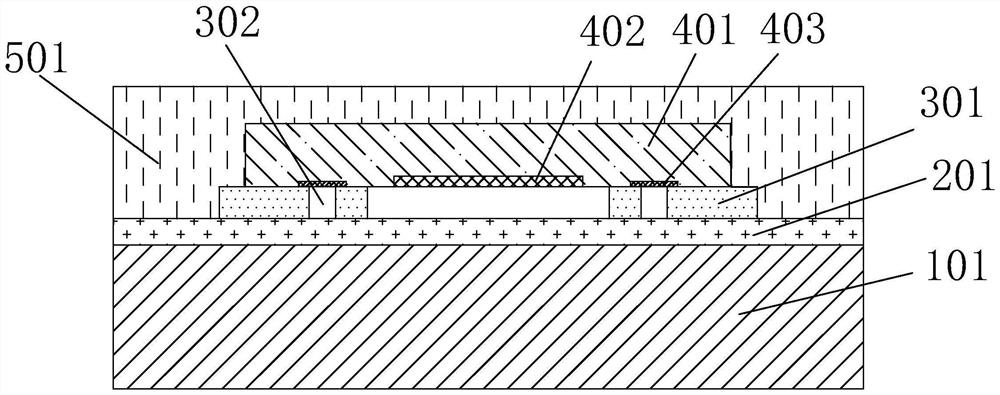

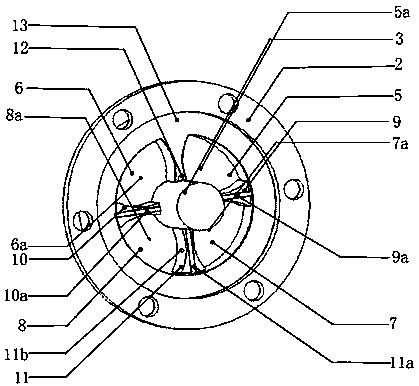

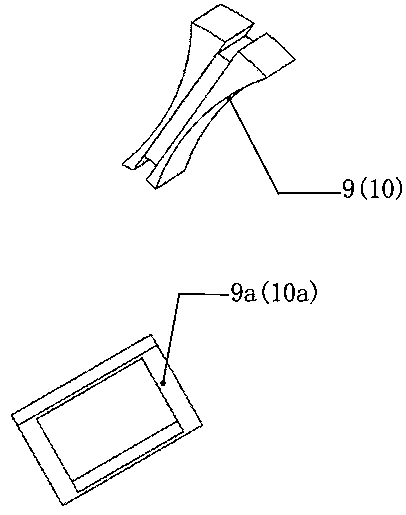

Filter fan-out packaging structure and manufacturing method thereof

The invention discloses a filter fan-out packaging structure and a manufacturing method thereof, a filter chip comprises a resonance area and a non-resonance area outside the resonance area, a bonding pad is arranged on the non-resonance area, a bonding layer covers the surface of an additionally provided carrier plate wafer, a barrier layer is manufactured above the bonding layer, and the barrier layer is arranged on the surface of the carrier plate wafer. An alignment structure is formed on an enclosure layer or a non-resonance area, the position of the alignment structure corresponds to a bonding pad, a filter chip is attached to a carrier plate wafer in an alignment mode through the alignment structure so as to form a first cavity above a resonance area, and the back face and the side face of the filter chip and the back face and the side face of the enclosure layer are covered with a plastic package layer. And removing the carrier wafer and the bonding layer, manufacturing a protective layer on the enclosure layer, and arranging a metal connecting structure and a solder ball through a first through hole in the protective layer and the alignment structure. According to the invention, the problems of offset of fan-out packaging of the filter chip and LT wafer cracking can be solved, the mold pressing resistance of the cavity structure is effectively enhanced, the production cost is reduced, and ultrathin packaging is realized.

Owner:XIAMEN SKY SEMICON TECH CO LTD

A kind of magnetic rubber seal composite material with high pressure change resistance and preparation method thereof

The invention relates to the field of functional magnetic sealing composite materials, and in particular provides a high pressure-resistant magnetic rubber sealing composite material and a preparation method thereof, which is mainly characterized by nitrile rubber, neoprene and magnetic powder and reinforcement, Composition of vulcanization and protection system, mixed by internal mixer and vulcanized by vulcanizer, the magnetic rubber sealing composite material has excellent dynamic sealing and static sealing, good solvent resistance, high resistance to pressure change, relatively Good thermal stability, magnetic stability and other characteristics.

Owner:QINGDAO UNIV OF SCI & TECH +2

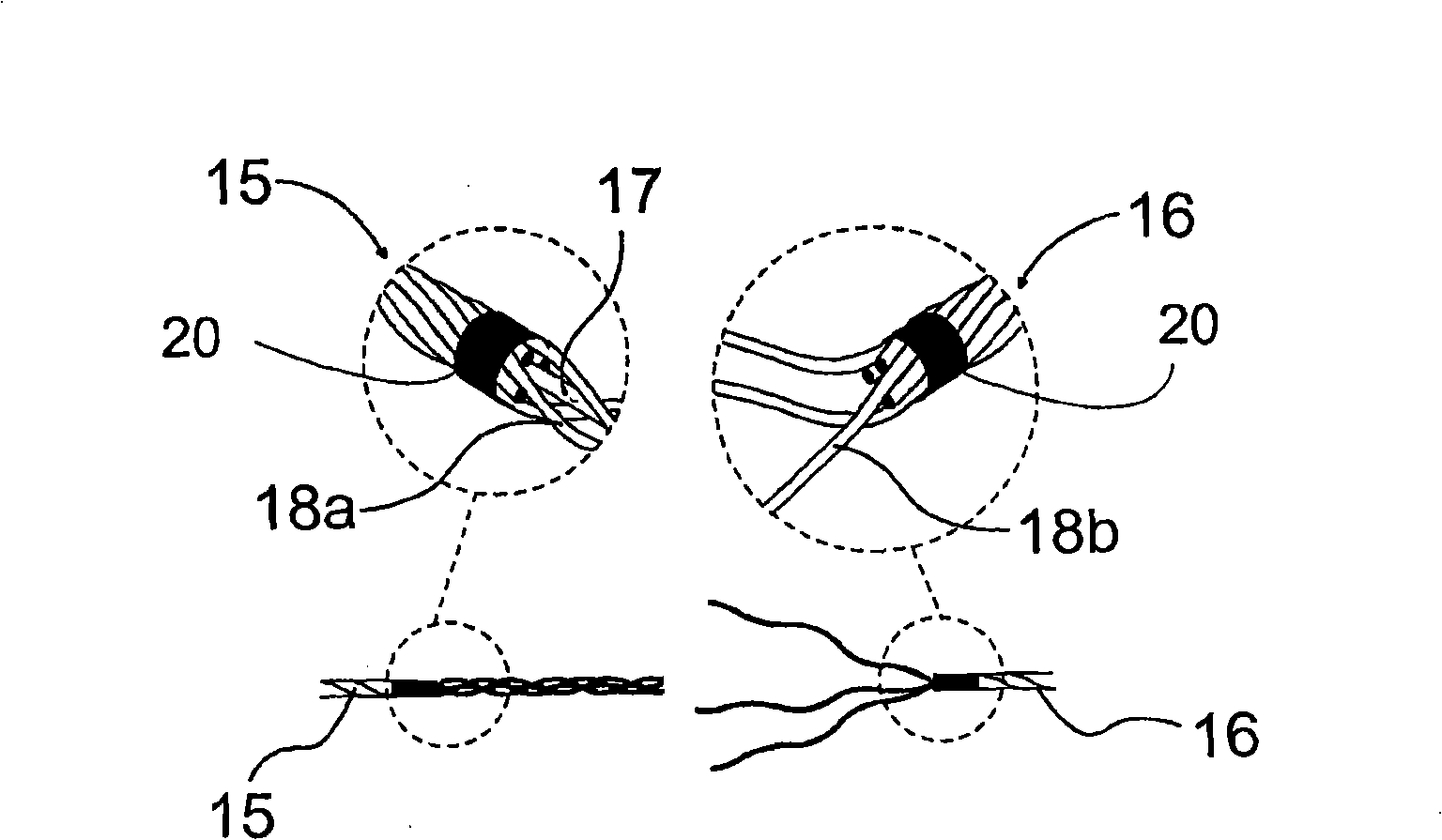

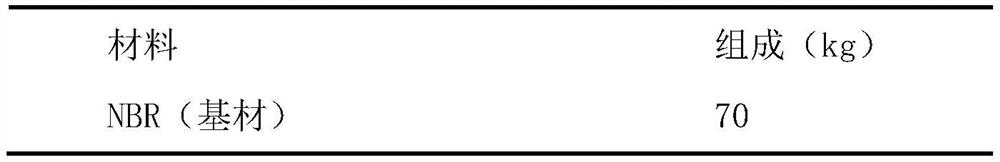

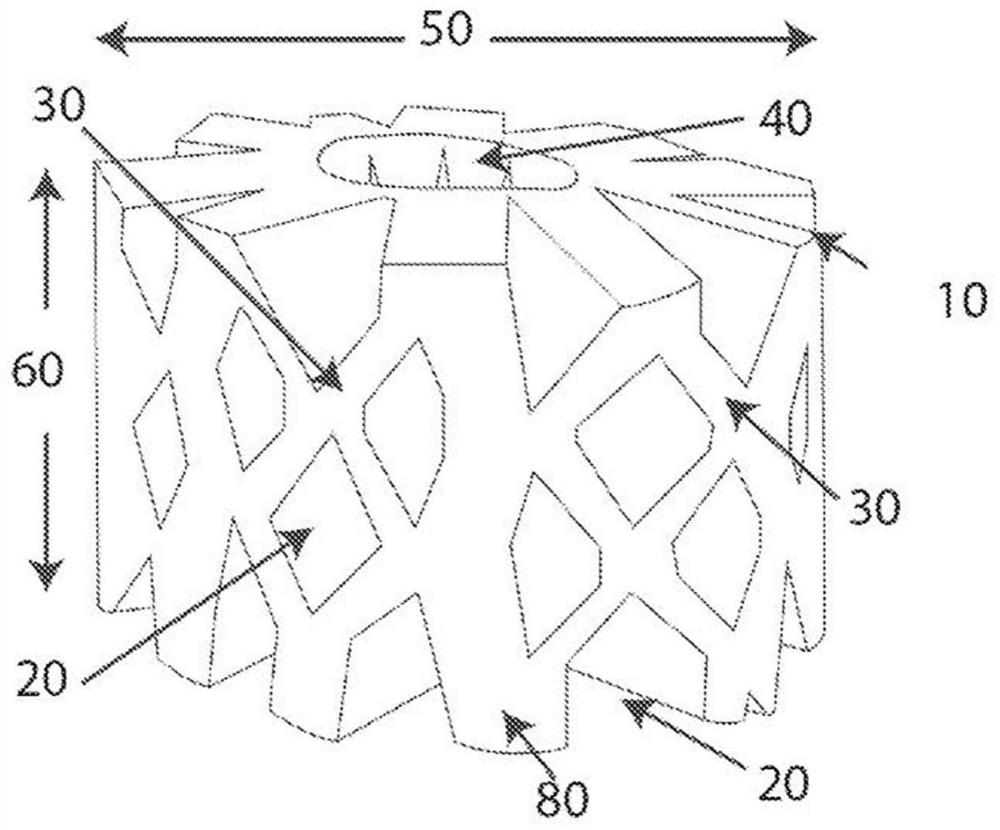

Hollow tubular center bulging foam spring

ActiveCN111787830AReduce production processStable supportPillowsStuffed mattressesEngineeringMaterials science

A hollow tubular foam spring (10) having a plurality of radially extending holes (20) extending from an outer surface (30) towards a central hollow core (40). The tubular foam spring (10) is arrangedwith wall thickness and diameter to height ratios such that center bulging is achieved under compressive loads. In an embodiment, such as in a mattress, seat, cushion or pillow, springs (10) are arranged in an array whereby some impinge upon one another due to central bulging.

Owner:ELISANA S A R L

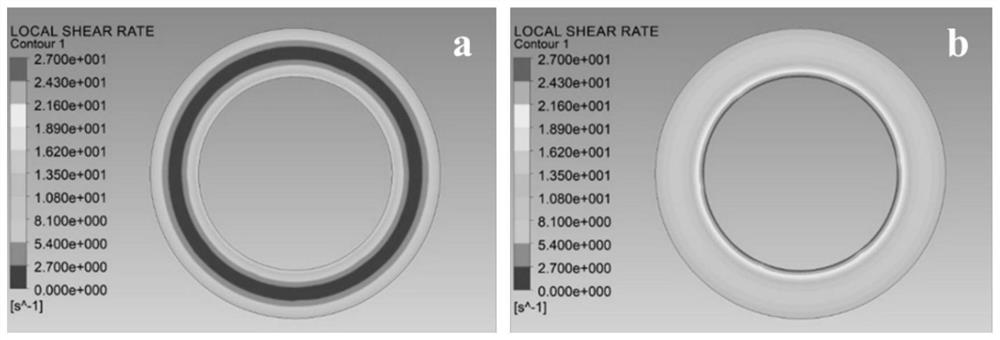

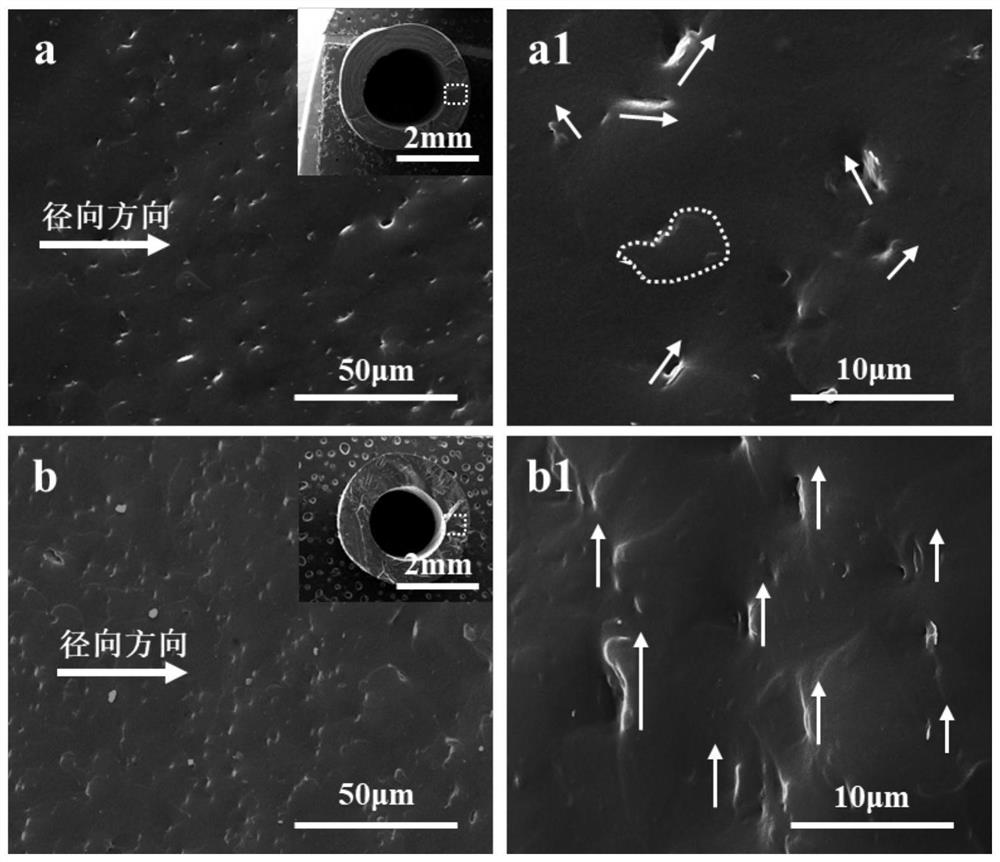

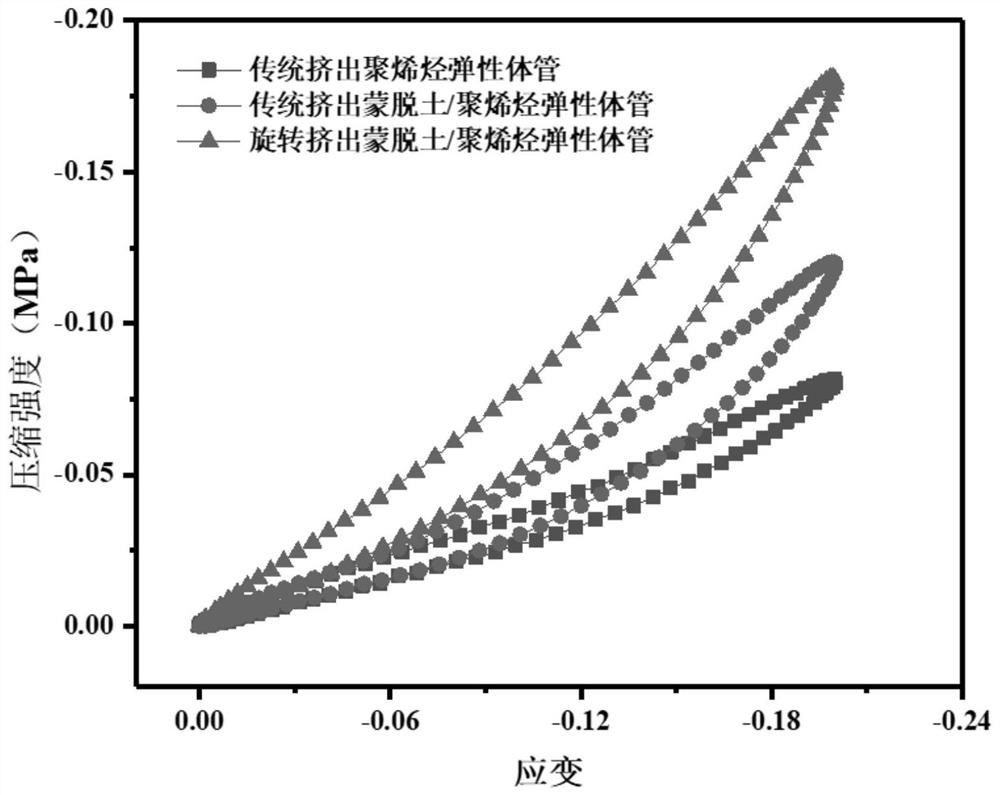

Polymer microcatheter with regular arrangement of two-dimensional sheet-like fillers and preparation method thereof

ActiveCN111251568BOvercoming completely disorderly technical issuesImprove compression resistancePolymer scienceCatheter

The present invention provides a polymer microcatheter with regular arrangement of two-dimensional flaky fillers in the microcosm and a preparation method thereof. Mix uniformly according to a certain ratio; (2) extrude the mixture obtained in step (1) through a high-performance polymer pipe preparation device with application number 200810045785.9, and obtain a two-dimensional flaky filler in the microscopic form. Aligned polymeric microcatheters. The polymer microcatheter has regular arrangement of two-dimensional sheet-like fillers in the radial direction, has excellent compression resistance and barrier performance, and has a simple process flow for its preparation method, can be produced continuously, and has industrialization prospects.

Owner:SICHUAN UNIV

A kind of bacterial cellulose/polypyrrole/polyurethane flexible multifunctional conductive composite material and preparation method thereof

ActiveCN110951109BImprove compression resistanceImprove flexibilityElectric heatingPolymer sciencePolypyrrole

The invention relates to a bacterial cellulose / polypyrrole / polyurethane flexible multifunctional conductive composite material and a preparation method thereof. Covered with polyurethane and three-proof finish. The obtained bacterial cellulose / polypyrrole / polyurethane porous composite material has the functions of electric heating, heat preservation, hydrophobicity and breathability when used as an electric heating material on clothing.

Owner:DONGHUA UNIV

Primer-topcoat epoxy heavy-duty anticorrosive coating

InactiveCN107573819ALow costCuring reaction is stableAnti-corrosive paintsEpoxy resin coatingsHeavy dutyToughening

The invention relates to primer-topcoat heavy-duty anticorrosive coating and belongs to the technical field of heavy-duty anticorrosive coating. The primer-topcoat heavy-duty anticorrosive coating ismainly characterized by comprising the following components in percentage by weight: 25%-35% of a low molecular weight bisphenol A glycidyl ether epoxy resin Epon828 base material, 10%-20% of a reaction type toughening diluent 277, 12%-35% of a cardanol-modified amine curing agent, 5%-10% of high-titanium powder pigment, 30%-40% of barium sulfate filler and 0.7%-2.4% of auxiliaries. The primer-topcoat heavy-duty anticorrosive coating provided by the invention has the advantages that all the key indexes thereof substantially exceed those of existing anticorrosive coating, the protection life ofthe high-performance coating with long-lasting protection in rigor and corrosive environment can reach more than 20 years, pollution can be reduced, the environment can be improved, resources can besaved, cost can be reduced, and economic benefit can be improved.

Owner:徐州尚铭装饰材料有限公司

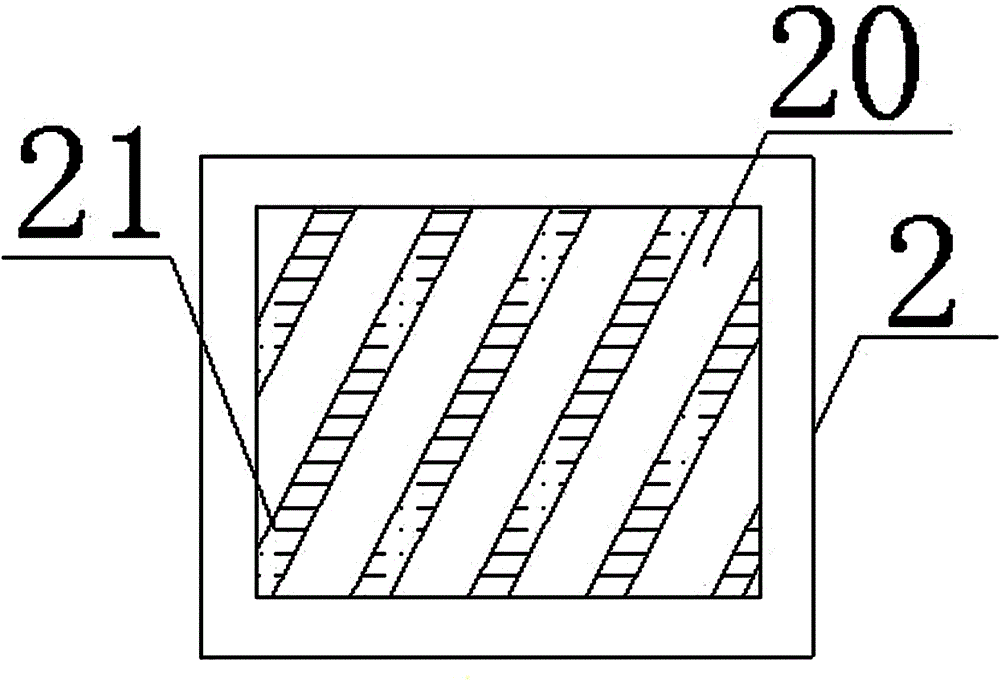

Processing technology for enhancing pressure change resistance of magnetic rubber

InactiveCN112457507AImprove compression resistanceReduce deformationCarbon fibresFibre chemical featuresFiberPolymer science

The invention discloses a processing technology for enhancing the pressure change resistance of magnetic rubber, and relates to the technical field of magnetic rubber processing. The specific technological method comprises the following steps of: S1, preparation of magnetic fibers; S2, preparation of a skeleton material; S3, preparation of a magnetic support member; and S4, processing and preparation of the magnetic rubber. According to the processing technology provided by the invention, the compression deformation quantity of the magnetic rubber can be effectively reduced, so that the pressure change resistance of the magnetic rubber is enhanced, and the magnetic rubber has more excellent sealing performance.

Owner:LINGBI COUNTY LINGCI NEW MATERIALS

An elastic firewall board

ActiveCN106049786BGood fire resistance and heat resistanceImprove toughnessCovering/liningsCeramicwareInsulation layerEngineering

The invention discloses an elastic fireproof wallboard which comprises a base layer, a frame layer, an adhesive layer, a plastering mortar layer, an insulation layer, a latex layer, a decorative coating and an abrasion-resistant layer. The base layer is covered by the frame layer. The frame layer is composed of a plurality of workpieces which are arranged in parallel or in a staggered mode and form filling cavities. The filling cavities are filled with filler. The frame layer is covered by the adhesive layer. The adhesive layer is covered by the plastering mortar layer. The plastering mortar layer is covered by the insulation layer. The insulation layer is covered by the latex layer. The upper surface of the latex layer is coated with the decorative coating made of decorative paint. The upper surface of the decorative coating is coated with the abrasion-resistant layer made of transparent abrasion-resistant paint.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

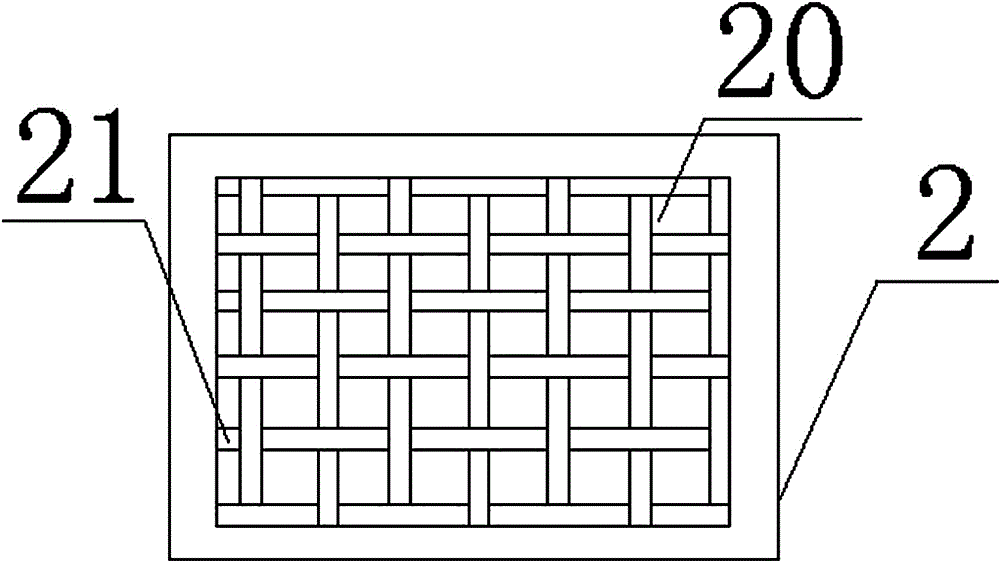

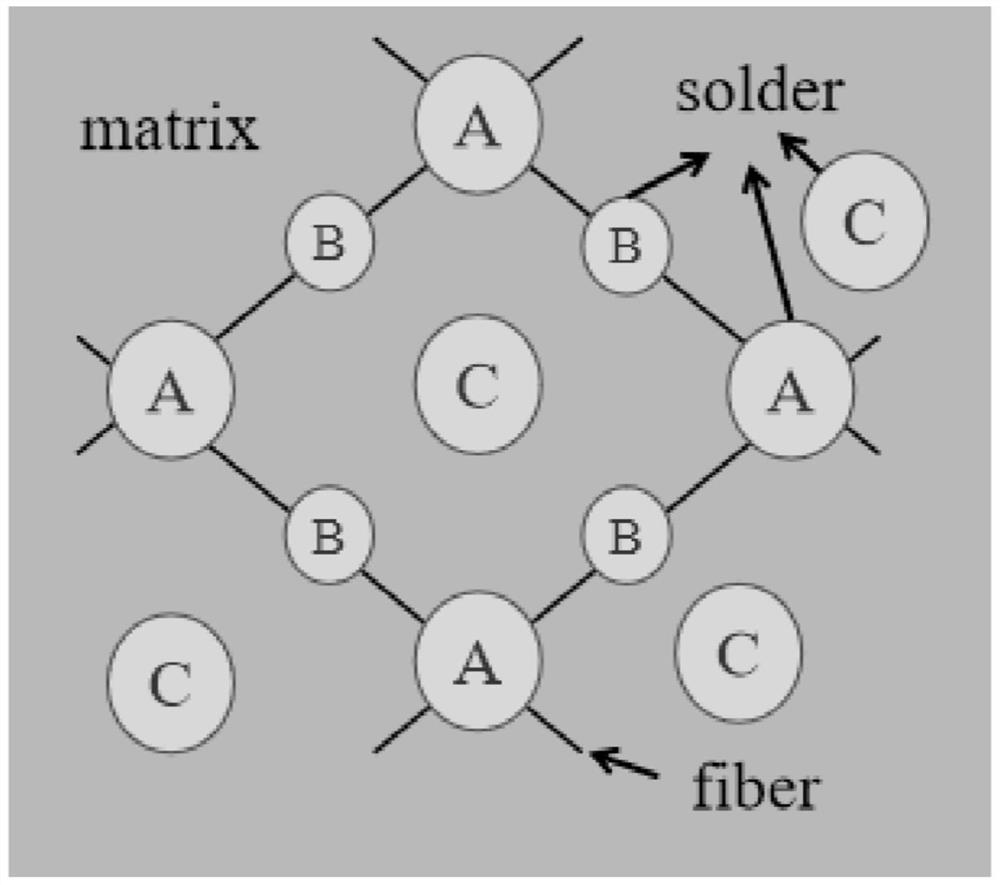

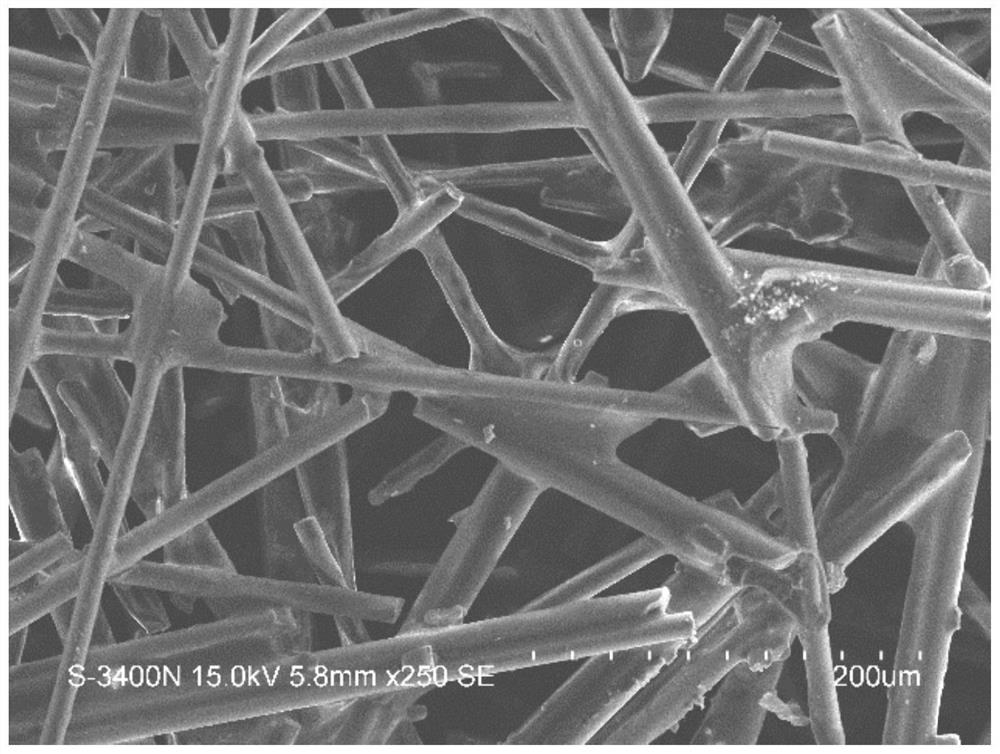

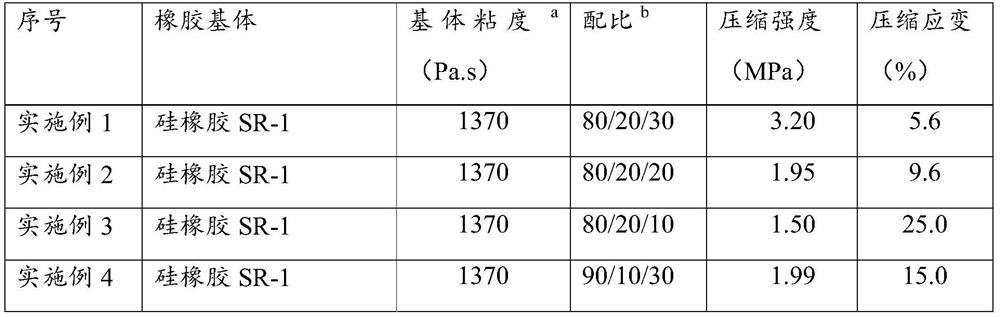

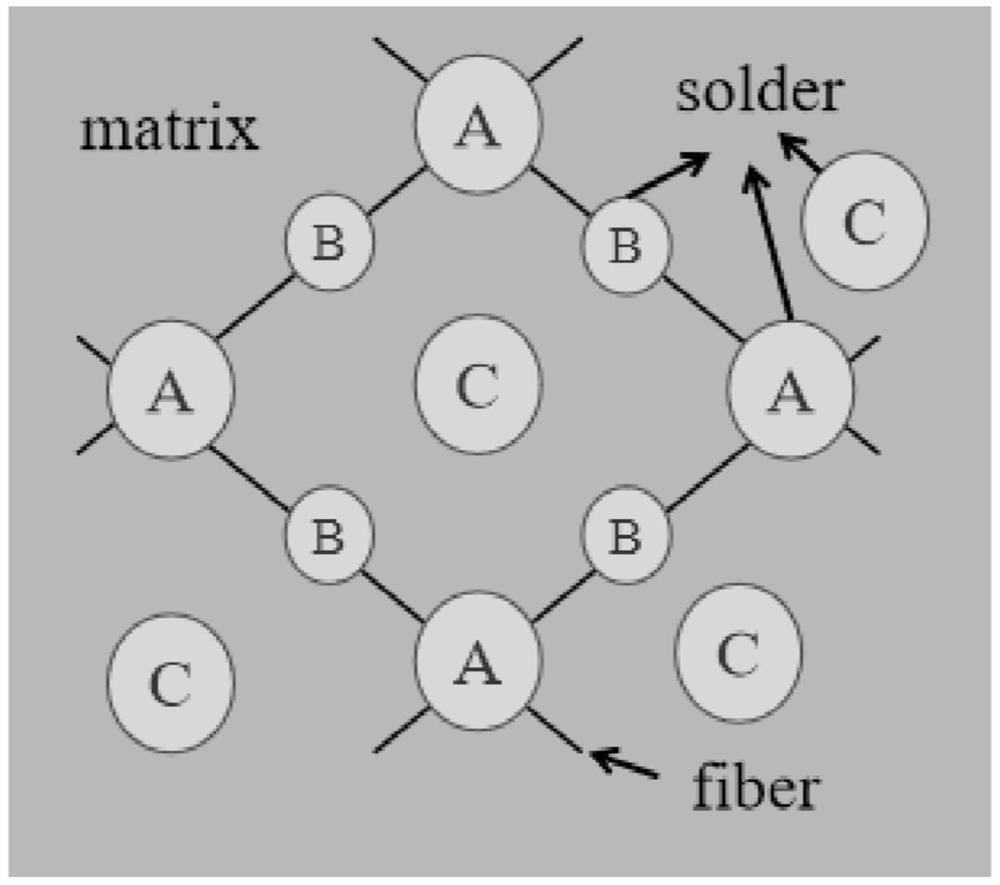

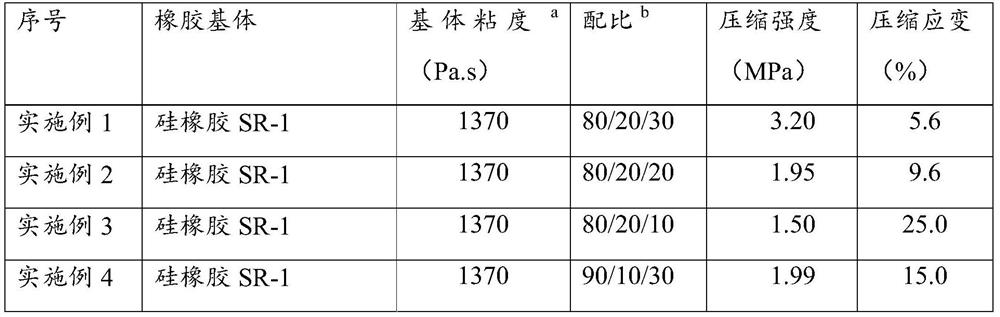

A kind of fiber-reinforced rubber-elastomer composite material and preparation method thereof

ActiveCN112831186BPlay a supporting roleImprove compression resistanceElastomer compositesReinforced rubber

The invention discloses a fiber-reinforced rubber elastic body composite material with good compression resistance, which includes a rubber matrix, fibers, and a thermosetting welding agent, and the thermosetting welding agent can promote spontaneous welding of fibers randomly dispersed in the rubber matrix during processing In essence, a three-dimensional network skeleton structure composed of thermosetting solder and fibers independent of the rubber matrix is formed; the thermosetting solder is a variety of thermosetting resins, which are flowing liquids before curing at room temperature and high-strength after curing. It is a solid; it is made of thermosetting resin, curing agent and accelerator with a mass ratio of 100:(50-100):(0-10). The present invention forms a self-welded fiber skeleton structure in the rubber matrix by adding thermosetting solder, which supports the rubber matrix, greatly improves the compression resistance of the rubber matrix, and is beneficial to broaden the rubber under pressure-resistant conditions. application.

Owner:EAST CHINA UNIV OF SCI & TECH

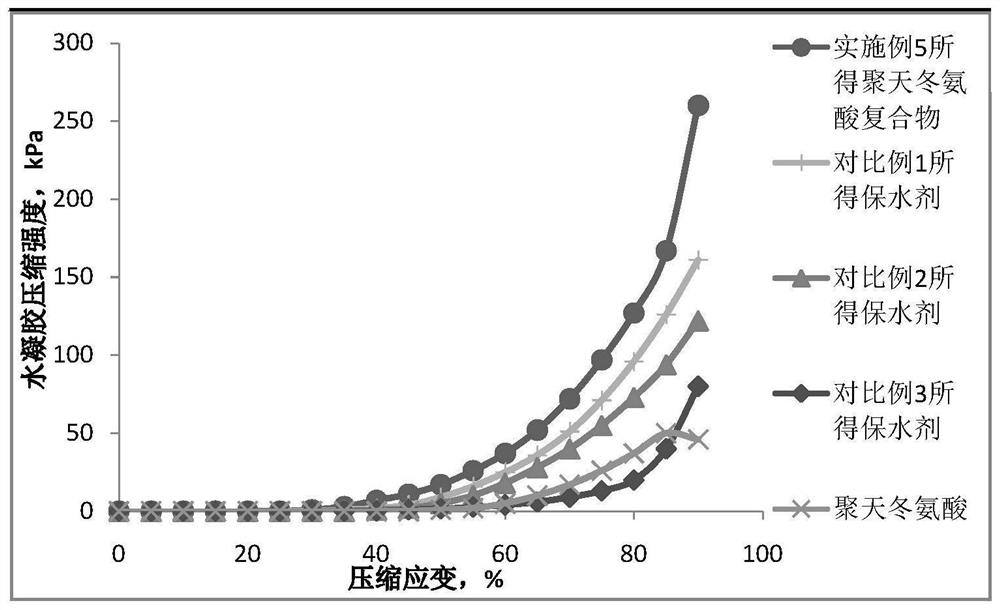

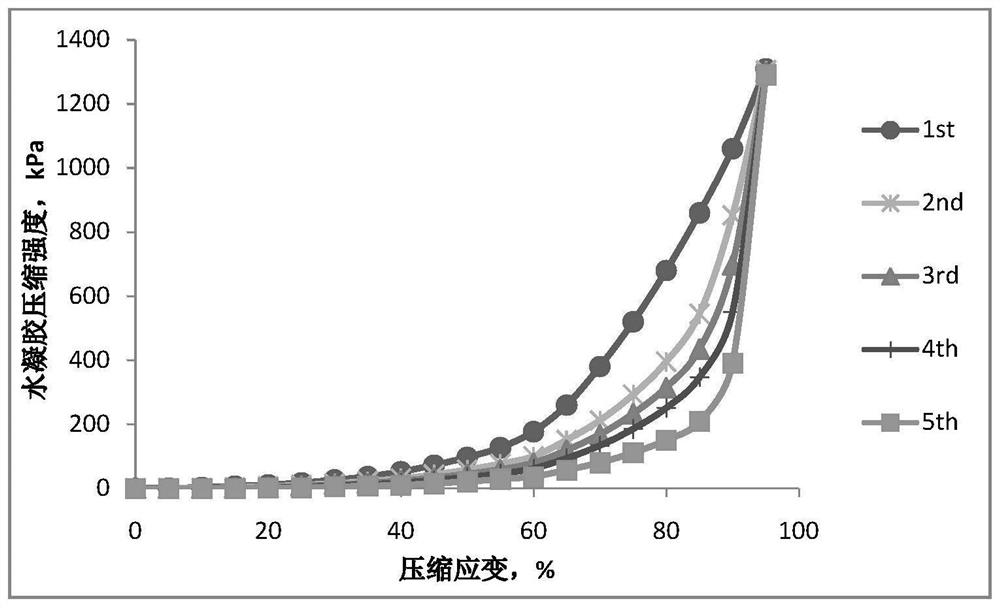

A kind of polyaspartic acid compound and its preparation method and application

ActiveCN109385283BStable supportImprove convenienceAgriculture tools and machinesOrganic fertilisersPhenylpropeneSodium hyaluronate

The invention discloses a preparation method of a polyaspartic acid complex, wherein the preparation method includes the steps: dissolving sodium hyaluronate in water, adjusting the pH value of the system to 5.8-6.4, adding carbodiimide and N-hydroxy succinimide successively in a stirring state, adding L-cysteine ethyl ester hydrochloride, and stirring to obtain a prefabricated material; and mixing polysuccinimide and a sodium hydroxide solution, adjusting the temperature, stirring, adjusting the pH value of the system to 4.8-5.5, adding the prefabricated material and phenylacrylamide, stirring, adding ethylene glycol diglycidyl ether, carrying out a reaction, precipitating with methanol, purifying, and carrying out vacuum drying to obtain the polyaspartic acid complex. The invention alsodiscloses the polyaspartic acid complex which is prepared by the preparation method of the polyaspartic acid complex. The invention also discloses an application of the polyaspartic acid complex. Thepolyaspartic acid complex has the advantages of excellent water absorption and release performance, high compressive strength, excellent thermal stability, remarkable prolonging of water retention time, and good soil improvement effect.

Owner:辽宁东北丰专用肥有限公司

Microporous polyolefin film and process for producing the same

ActiveCN101155861BImprove breathabilityHigh mechanical strengthMembranesSemi-permeable membranesPolyolefinPolymer science

The microporous polyolefin film produced by drawing a gel molding containing a polyolefin and a solvent for film formation in at least a uniaxial direction, performing thermofixing treatment, removing the solvent for film formation and once more drawing the molding in at least a uniaxial direction has large pore diameter and excels in air permeability, mechanical strength and compression resistance.

Owner:TORAY IND INC

High-quality foam fracturing fluid and preparation method and application thereof

InactiveCN113861958AImprove compression resistanceGood shear stabilityDrilling compositionThermodynamicsFoaming agent

The invention discloses a high-quality foam fracturing fluid and a preparation method and application thereof, and the high-quality foam fracturing fluid is prepared from the following raw material components in parts by mass: 0.217 to 1.694 parts of a stabilizer, 0.394 to 3.388 parts of a compounding agent, 1.183 to 6.776 parts of a foaming agent, 0.986 to 6.098 parts of a foam stabilizer and 98.6 to 169.4 parts of water, the high-quality foam fracturing fluid with the density of 0.683 g / cm < 3 >-0.879 g / cm < 3 > can be prepared by mixing and stirring the raw material components. The high-quality foam fracturing fluid overcomes the defects that an existing low-density foam fracturing fluid is short in foam stabilizing time, low in foaming rate, uneven in foaming size, not resistant to high temperature and the like, the preparation process is simple, construction is easy, and the high-quality foam fracturing fluid is suitable for yield increasing transformation of low-pressure low-permeability, leakage and water-sensitive stratums.

Owner:BETTER OILFIELD TECH

A flame retardant insulation board

ActiveCN106049695BGood fire resistance and heat resistanceImprove toughnessHeat proofingFire proofingInsulation layerEngineering

The invention discloses a flame-retardant insulation board which comprises a base layer, a frame layer, an adhesive layer, a waterproof layer, an insulation layer, an elastic buffer layer and an abrasion-resistant coating. The base layer is covered by the frame layer. The frame layer is composed of a plurality of workpieces which are arranged in parallel or in a staggered mode and form filling cavities. The filling cavities are filled with filler. The frame layer is covered by the adhesive layer. The adhesive layer is covered by the waterproof layer. The waterproof layer is covered by the insulation layer. The insulation layer is covered by the elastic buffer layer. The upper surface of the elastic buffer layer is coated with the abrasion-resistant coating made of abrasion-resistant paint.

Owner:ANHUI DEQUAN NEW BUILDING MATERIALS TECH CO LTD

Fiber-reinforced rubber elastomer composite material and preparation method thereof

ActiveCN112831186APlay a supporting roleImprove compression resistanceReinforced rubberFiber reinforcement

The invention discloses a fiber-reinforced rubber elastomer composite material with good compression resistance, which comprises a rubber matrix, fibers and a thermosetting welding agent, and the thermosetting welding agent can promote the fibers randomly dispersed in the rubber matrix to be spontaneously welded together in the processing process. A three-dimensional network skeleton structure which is formed by the thermosetting welding agent and the fibers and is independent of the rubber matrix is substantially formed. The thermosetting welding agent is various thermosetting resins, is a flowing liquid before being cured at normal temperature, and is a high-strength solid after being cured. The thermosetting resin is prepared from thermosetting resin, a curing agent and an accelerant according to the mass ratio of 100:(50-100):(0-10). By adding the thermosetting welding agent, a self-welding fiber skeleton structure is formed in the rubber matrix, a supporting effect on the rubber matrix is achieved, the compression resistance of the rubber matrix is greatly improved, and the application range of rubber under the pressure-resistant condition is widened.

Owner:EAST CHINA UNIV OF SCI & TECH

A kind of EVA coarse cell composite foam material and preparation method

The invention discloses an EVA coarse-pore composite foaming material and a preparation method thereof, which is prepared by mixing, granulating and foaming the material; the material includes: 40-60 parts by mass of ethylene-vinyl acetate copolymer, graphene Modified isotactic polybutene 10-20 mass parts, polyolefin thermoplastic elastomer 10-15 mass parts, polyester elastomer 10-20 mass parts, active agent 0.4-0.8 mass parts, crosslinking agent 0.7-1.5 mass parts 2.5-3.5 parts by mass of foaming agent and 0.1-0.3 parts by mass of auxiliary agent; the mass content of vinyl acetate in ethylene-vinyl acetate copolymer is 26%-40%; the preparation method of the EVA coarse-cell composite foaming material , take quantitative isotactic polybutene-1 and melt, add mass content and be 0.05%-0.2% graphene when the melting temperature of isotactic polybutene-1 is 140-170 ℃, so that both mixing Obtain graphene-modified isotactic polybutene afterward; The foaming effect of its coarse-cell foaming of this EVA coarse-cell composite foaming material is good, and has improved compression-resistant performance and resilience performance, and softness and abrasion-resistance are also improved. improved. The preparation method is simple and easy to operate.

Owner:ANTA CHINA

A kind of oil-pneumatic torsion spring

ActiveCN107345552BReconcile component heterogeneityEasy to compressSpringsGas and liquid based dampersDamping factorGas chamber

Owner:安徽东华弹簧有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com