Heat insulation fireproof wallboard

A firewall board and thermal insulation technology, applied in building components, buildings, building structures, etc., can solve problems such as poor fire resistance, achieve excellent fire resistance and heat resistance, high toughness and adhesion, and reduce thermal conductivity and density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

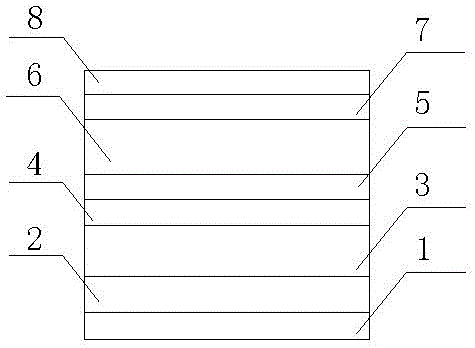

[0026] Such as figure 1 as shown, figure 1 It is a schematic diagram of a thermal insulation fire wall panel proposed by the present invention.

[0027] refer to figure 1 , a thermal insulation fire wall panel proposed by the present invention, comprising a base layer 1, an inner fiberboard layer 2 attached above the base layer 1, an insulating layer 3 attached above the inner fiberboard layer 2, and a vacuum layer attached above the insulating layer 3 4. The protective layer 5 attached above the vacuum layer 4, the outer fiberboard 6 attached above the protective layer 5, the waterproof layer 7 attached above the outer fiberboard 6, and the reflective layer 8 attached above the waterproof layer 7;

[0028] Wherein, the preparation method of insulation layer 3 is as follows:

[0029] S1. Add 10-(2,5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphaphenanthrene-10-oxide and polyvinylbenzoic acid into dichloromethane and mix uniformly to obtain, Then add dicyclohexylcarbodiimide, 4...

Embodiment 2

[0033] A thermal insulation firewall board, comprising a base layer 1, an inner fiber board layer 2 attached above the base layer 1, an insulation layer 3 attached above the inner fiber board layer 2, a vacuum layer 4 attached above the insulation layer 3, and attached to the The protective layer 5 above the vacuum layer 4 is attached to the outer fiberboard 6 above the protective layer 5, the waterproof layer 7 attached to the top of the outer fiberboard 6, and the reflective layer 8 attached to the top of the waterproof layer 7; the thickness of the outer fiberboard 6 is The sum of the thicknesses of the vacuum layer 4 and the protective layer 5.

[0034] Wherein, the preparation method of insulation layer 3 is as follows:

[0035] S1. Add 10-(2,5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphaphenanthrene-10-oxide and polyvinylbenzoic acid into dichloromethane and mix uniformly to obtain, Then dicyclohexylcarbodiimide, 4-dimethylaminopyridine, and p-toluenesulfonic acid were ad...

Embodiment 3

[0039] A thermal insulation firewall board, comprising a base layer 1, an inner fiber board layer 2 attached above the base layer 1, an insulation layer 3 attached above the inner fiber board layer 2, a vacuum layer 4 attached above the insulation layer 3, and attached to the The protective layer 5 above the vacuum layer 4, the outer fiberboard 6 attached above the protective layer 5, the waterproof layer 7 attached above the outer fiberboard 6, and the reflective layer 8 attached above the waterproof layer 7;

[0040] Wherein, the preparation method of insulation layer 3 is as follows:

[0041] S1. Add 155 parts by weight of 10-(2,5-dihydroxyphenyl)-10-hydrogen-9-oxa-10-phosphaphenanthrene-10-oxide and 76 parts of polyvinylbenzoic acid into two Mix well in methyl chloride, then add 135 parts of dicyclohexylcarbodiimide, 61 parts of 4-dimethylaminopyridine, 80 parts of p-toluenesulfonic acid dropwise, then raise the temperature to 50°C, reflux for 4h, during the reflux process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com