High-performance priming and finishing combined paint with corrosion inhibition, pollution prevention and heavy corrosion protection functions

A heavy-duty, high-performance technology, used in anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve the problems that the bottom surface cannot be integrated, and cannot be resistant to strong acid and alkali at the same time, and achieve a good response Active, excellent salt water resistance, safe in operation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

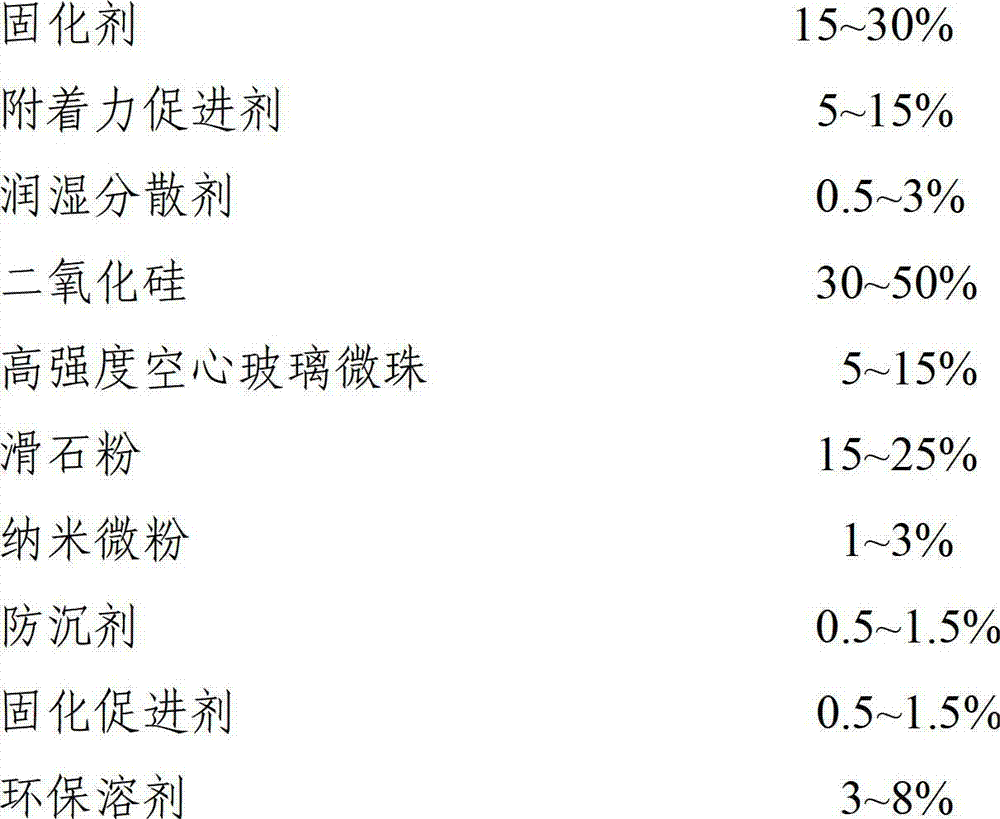

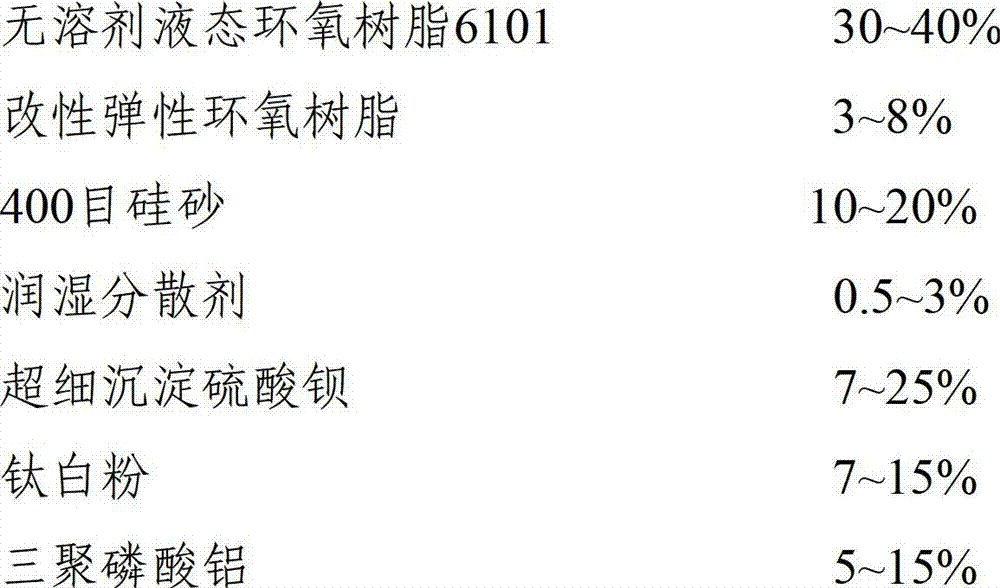

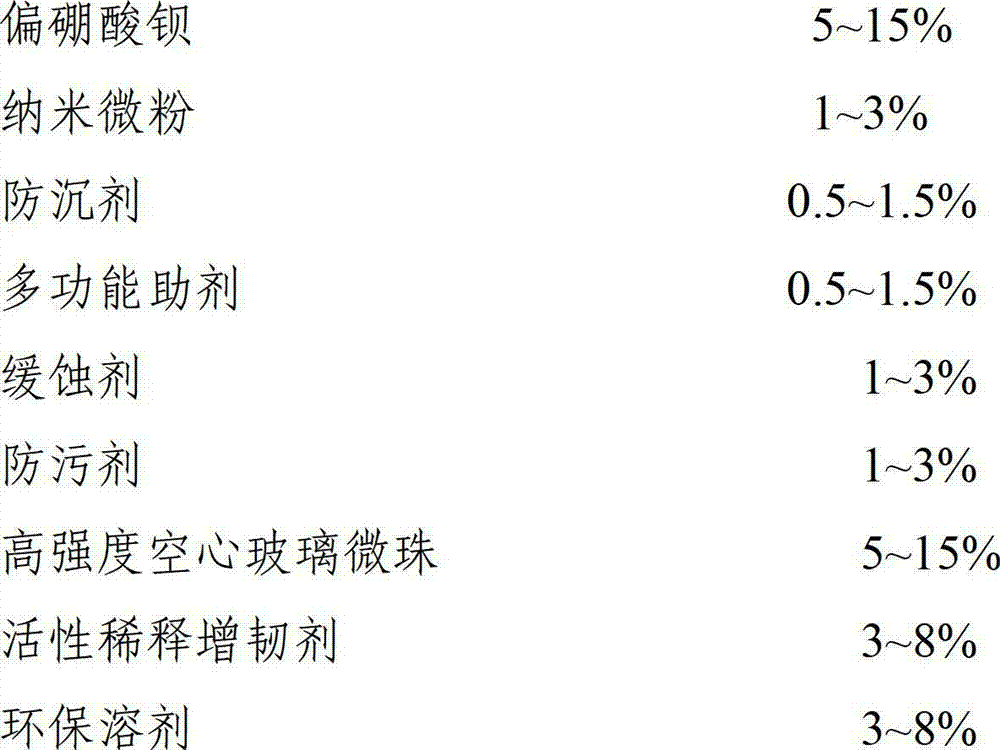

[0033] A high-performance corrosion-inhibiting, anti-fouling, heavy-duty, anti-corrosion, bottom-surface all-in-one coating, the coating includes component A and component B, and component A includes components with the following weight percentages:

[0034]

[0035] Part B includes ingredients with the following weight percentages:

[0036]

[0037]

[0038] The ratio of the A component to the B component is: 1:1.6.

Embodiment 2

[0040] A high-performance corrosion-inhibiting, anti-fouling, heavy-duty, anti-corrosion, bottom-surface all-in-one coating, the coating includes component A and component B, and component A includes components with the following weight percentages:

[0041]

[0042] Part B includes ingredients with the following weight percentages:

[0043]

[0044]

[0045] The ratio of the A component to the B component is: 1:1.4.

Embodiment 3

[0047] A high-performance corrosion-inhibiting, anti-fouling, heavy-duty, anti-corrosion, bottom-surface all-in-one coating, the coating includes component A and component B, and component A includes components with the following weight percentages:

[0048]

[0049] Part B includes ingredients with the following weight percentages:

[0050]

[0051]

[0052] The ratio of the A component to the B component is: 1:1.5.

[0053] Performance test of the coating and comparison with commercially available heavy-duty anti-corrosion paint:

[0054] Tinplate is used as the substrate, the specification is 50×150, the high-performance anti-corrosion, anti-fouling and heavy-duty anti-corrosion coating is gray, the preparation of the paint film sample is carried out according to GB / T1727, and the plate is made according to 2.kg / m2 when painting , the comparison between the product performance and the commercially available heavy-duty anti-corrosion paint is shown in the table bel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com