Application of SEBS (styrene-ethylene-butylene-styrene) in sports equipment preparation process as foaming modifier

A preparation process and technology for sports equipment, which is applied in the application field of SEBS as a foaming modifier in the preparation process of sports equipment, and achieves the effect of high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

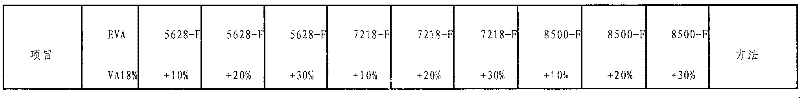

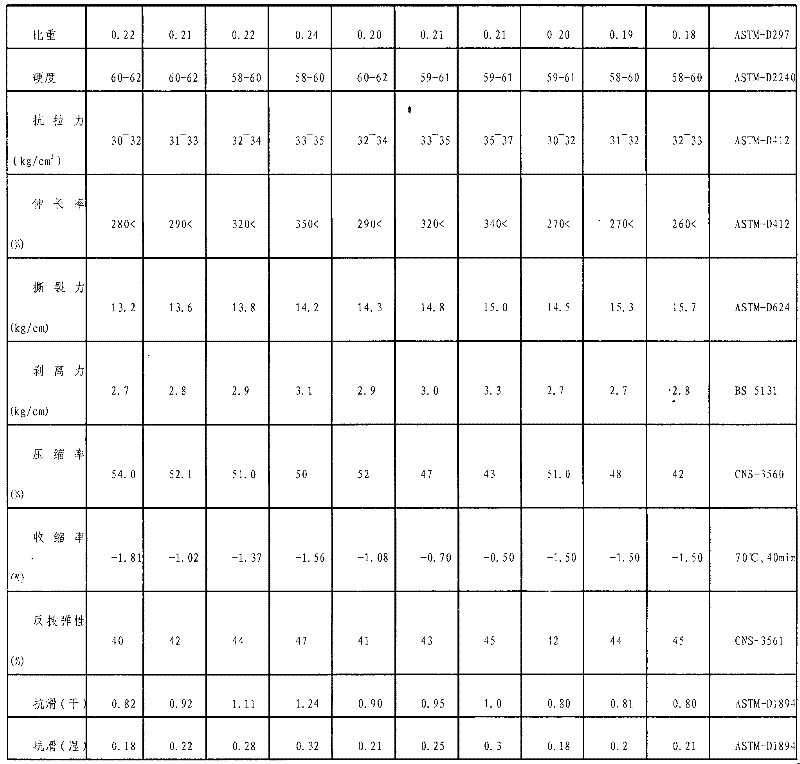

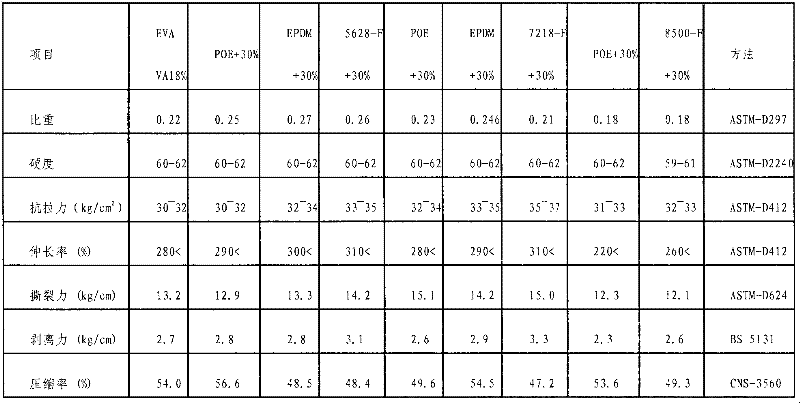

[0015] This embodiment is a specific application of adding SEBS as a foaming agent in the preparation process of sports materials.

[0016] When 5628-F is introduced into the EVA foam material or foamed with pure 5628-F, the foam material will become softer in touch and softer in hardness, with a high-quality feeling similar to rubber foam material. It has good dimensional stability when used in sports shoes, good thermal stability during container transportation, small compression deformation and good surface haze when made into insoles. For example, in the process of making insoles, EVA can also be modified to resist compression and deformation.

[0017] When 8500-F is introduced into the EVA foam material, the expansion rate will increase under the condition that the hardness of the foam material remains unchanged, so the specific gravity of the foam material will also decrease, so as to achieve the purpose of lightweight modification . Therefore, the outsole in the shoe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com