Pipe screw coupling

A technology for threaded joints and pipes, applied in the direction of threaded connections, pipes/pipe joints/pipes, drill pipes, etc., can solve problems such as mechanical damage of the threaded part, and achieve the effect of improving mechanical damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

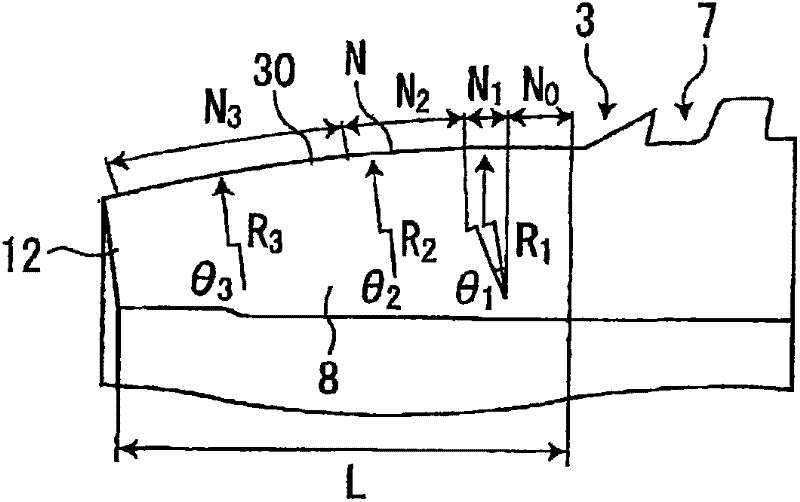

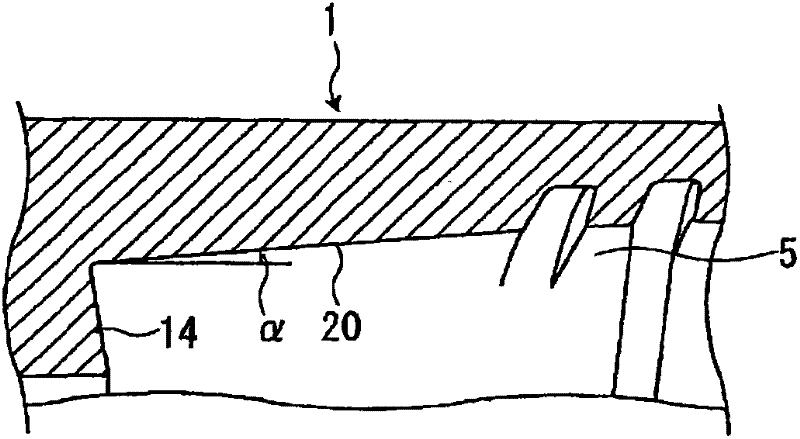

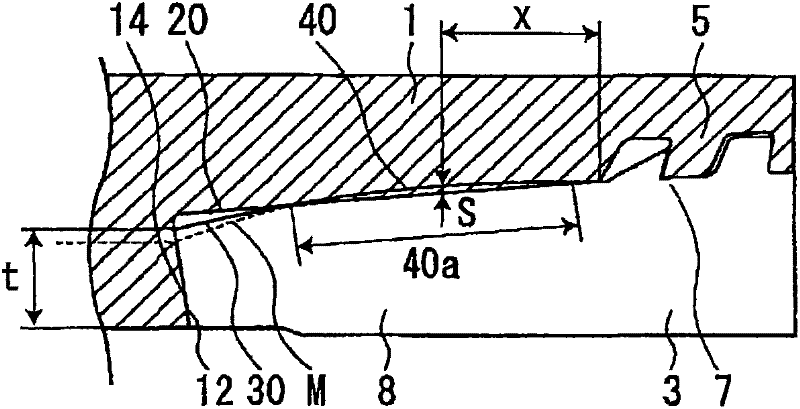

[0071] As an example of the invention, evaluation was performed on a threaded joint for pipes according to the present invention, which is shown in FIG. 1(a) or in which any two arcs of the compound arc curve in FIG. 1(a) are connected via a line segment. . Table 1 and Table 2 show the dimensions, shapes and evaluation results of Examples of the present invention and Comparative Examples. The pin member is formed at the tip of a steel pipe with an outer diameter of 244.48 mm and a wall thickness of 13.84 mm. Also, the thread is formed with 5TPI (five threads per inch). As an evaluation based on FEM analysis, a leak test based on ISO13679:2002 was simulated, and the contact surface pressure (ksi·inch) at the sealed part of the test was evaluated. In addition, the contact surface pressure is calculated by integrating the contact surface pressure in the seal contact area. For this leak test, a pipe threaded joint is subjected to a biaxial stress corresponding to 95% of the yie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com