A kind of EVA coarse cell composite foam material and preparation method

A composite foaming and coarse-pored technology, which is used in shoe soles, clothing, footwear, etc., can solve the problems of excellent texture, wear resistance, and uncomfortable wearing, and achieves a reduction in crystallization ability, good resilience, and improved aesthetics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] Correspondingly, the embodiment of the present invention also provides a preparation method of the EVA coarse-cell composite foam material, comprising the following steps:

[0045] Step 1: Take quantitative isotactic polybutene-1 and melt it, and add mass content of 0.05%-0.2% graphene when the melting temperature of isotactic polybutene-1 is 140-170°C, so that both Graphene-modified isotactic polybutene-1 is obtained after mixing; the mixing time is 25-40 minutes, and the temperature is 150-180°C;

[0046] Step 2: taking each component in the material by weight fraction;

[0047] Step 3: Mix the other components weighed in step 2 except the crosslinking agent and foaming agent; the mixing time is 8-15 minutes, and the temperature is 100-110°C.

[0048] Step 4: Mix the material mixed in step 3 with the weighed crosslinking agent and foaming agent in step 2; the mixing time is 3-5 minutes, and the temperature is 110-120°C.

[0049] Step 5: The mixture obtained after kn...

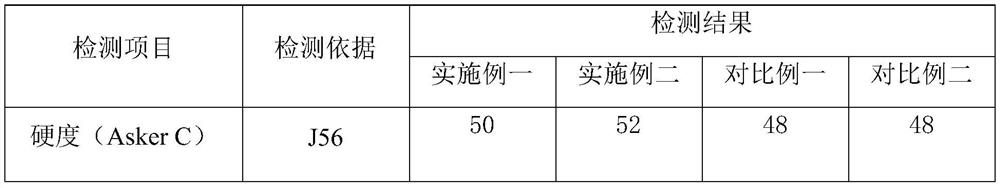

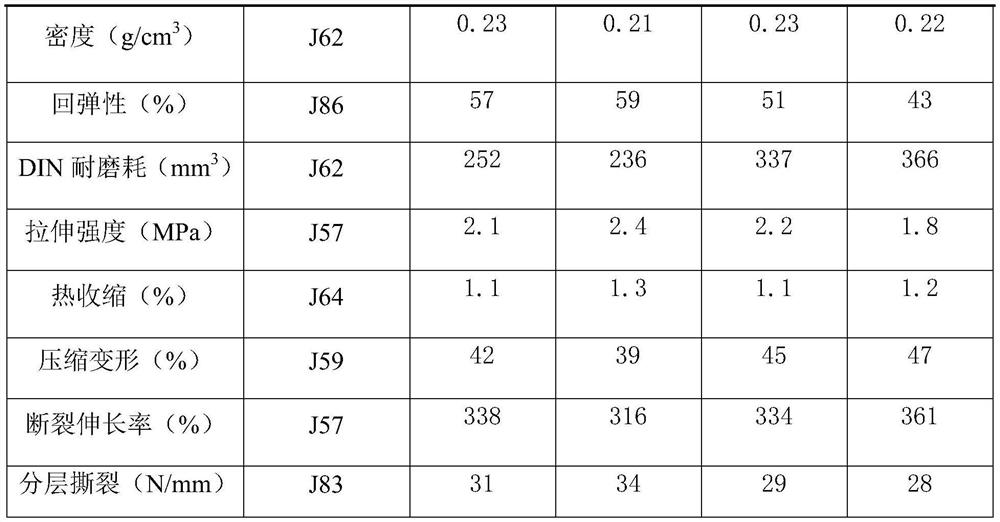

Embodiment 1

[0054] In Embodiment 1 of the present invention, the proportioning by mass of the materials contained in the EVA coarse-cell composite foaming material is as follows:

[0055] Ethylene-vinyl acetate copolymer: 45 parts by mass

[0056] Graphene-modified isotactic polybutene-1:15 parts by mass

[0057] Polyolefin thermoplastic elastomer: 15 parts by mass

[0058] Polyester elastomer: 15 parts by mass

[0059] Active agent: 0.6 parts by mass

[0060] Crosslinking agent: 1.2 parts by mass

[0061] Foaming agent: 3.0 parts by mass

[0062] Auxiliary: 0.3 parts by mass

[0063] Among them, the model of ethylene-vinyl acetate copolymer is 7470M, produced by Formosa Plastics Corporation; polybutene is commercially available from Shandong Dongfang Hongye Chemical Co., Ltd.; graphene is commercially available; the polyolefin thermoplastic elastomer models are Engage8180 and Engage8450, and its The ratio is 2:1, produced by DuPont; the type of polyester elastomer is DSM EL430; the...

Embodiment 2

[0070] In the second embodiment of the present invention, the mass proportions of the materials contained in the EVA coarse-cell composite foaming material are as follows:

[0071] Ethylene-vinyl acetate copolymer: 40 parts by mass

[0072] Graphene-modified isotactic polybutene-1:20 parts by mass

[0073] Polyolefin thermoplastic elastomer: 10 parts by mass

[0074] Polyester elastomer: 10 parts by mass

[0075] Active agent: 0.8 parts by mass

[0076] Crosslinking agent: 1.5 parts by mass

[0077] Foaming agent: 2.8 parts by mass

[0078] Auxiliary: 0.2 parts by mass

[0079] Among them, the model of ethylene-vinyl acetate copolymer is 7470M, produced by Formosa Plastics Corporation; polybutene is commercially available from Shandong Dongfang Hongye Chemical Co., Ltd.; graphene is commercially available; the polyolefin thermoplastic elastomer models are Engage8180 and Engage8450, and its The ratio is 1:1, produced by DuPont; the type of polyester elastomer is DSM EL430...

PUM

| Property | Measurement | Unit |

|---|---|---|

| resilience | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

| resilience | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com