Ultralight EVA composite foaming material and preparation method thereof

A composite foaming and foaming agent technology, which is applied in the field of ultra-light EVA composite foaming materials and its preparation, can solve the problems affecting the wearing experience and appearance of shoes, the loss of elasticity of the soles, and the tendency to collapse, and achieves good user experience. Good softness and comfort, the effect of reducing crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

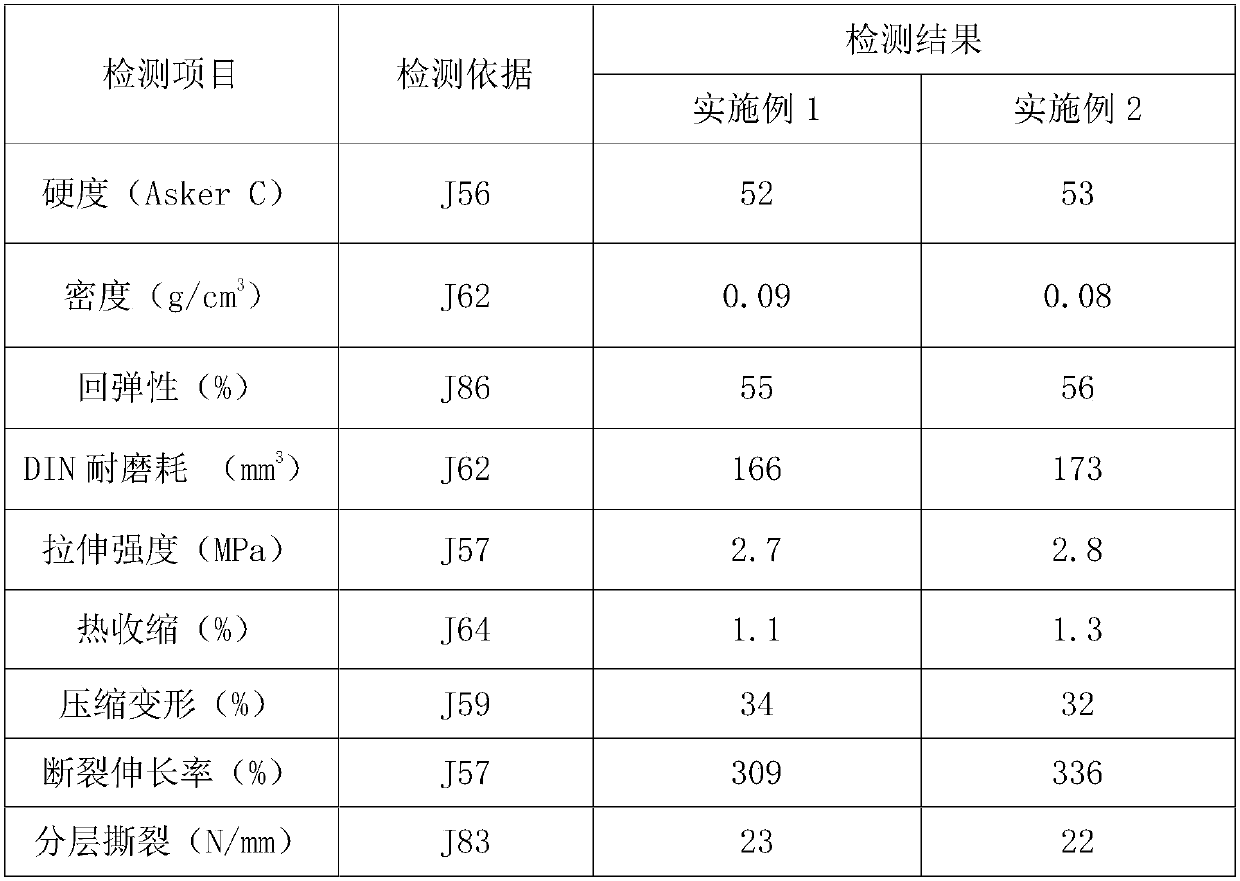

Examples

Embodiment 1

[0025] An ultra-light EVA composite foam material, in parts by mass, including 42 parts of ethylene-vinyl acetate copolymer, 30 parts of polyolefin block copolymer, 17 parts of PP elastomer, 13 parts of PS elastomer, 5 parts of filler part, 0.5 part of activator, 1 part of crosslinking agent, 3.1 parts of foaming agent; 3.1 parts of auxiliary agents, 2 parts of zinc oxide, 1 part of zinc stearate and 0.1 part of crosslinking auxiliary agent are used.

[0026] Wherein, the model of ethylene-vinyl acetate copolymer is one or more of EVA7470M, EVA460, EVA462, EVA265, EVA40L-03, EVA40W, preferably EVA7470M in this embodiment; the model of polyolefin block copolymer is Infuse9100, One or more of Infuse9107, Infuse9500, and Infuse9507, Infuse9107 is preferred in this embodiment; the PP elastomer is an ethylene-propylene rubber copolymer, and the melting point of the ethylene-propylene rubber copolymer is 65-85°C; the bending strength of the PS elastomer is 18-36MPa, tensile strength...

Embodiment 2

[0032] An ultra-light EVA composite foam material, in parts by mass, including 50 parts of ethylene-vinyl acetate copolymer, 25 parts of polyolefin block copolymer, 20 parts of PP elastomer, 15 parts of PS elastomer, and 5 parts of filler parts, 0.5 parts of active agent, 1.2 parts of crosslinking agent, 3 parts of foaming agent, 2.97 parts of auxiliary agent, 2 parts of zinc oxide, 0.8 part of zinc stearate, and 0.17 part of crosslinking auxiliary agent.

[0033] Wherein, the ethylene-vinyl acetate copolymer model is one or more of EVA7470M, EVA460, EVA462, EVA265, EVA40L-03, EVA40W, and the preferred models of ethylene-vinyl acetate copolymer in the present embodiment are EVA265 and EVA40W, And the ratio of parts by weight of EVA265 and EVA40W is 2:1; the type of polyolefin block copolymer is one or more of Infuse9100, Infuse9107, Infuse9500, Infuse9507, Infuse9107 is preferred in this embodiment; PP elastomer is B Propylene rubber copolymer, and the melting point of ethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com