Bacterial cellulose/polypyrrole/polyurethane flexible multifunctional conductive composite material and preparation method thereof

A technology of conductive composite material and bacterial cellulose, which is applied in the field of bacterial cellulose/polypyrrole/polyurethane flexible multifunctional conductive composite material and its preparation, and can solve the problem of lack of thermal insulation, poor air permeability, poor electrical conductivity, etc. problems, to achieve the effect of enhancing mechanical properties, preventing heat loss, and improving compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

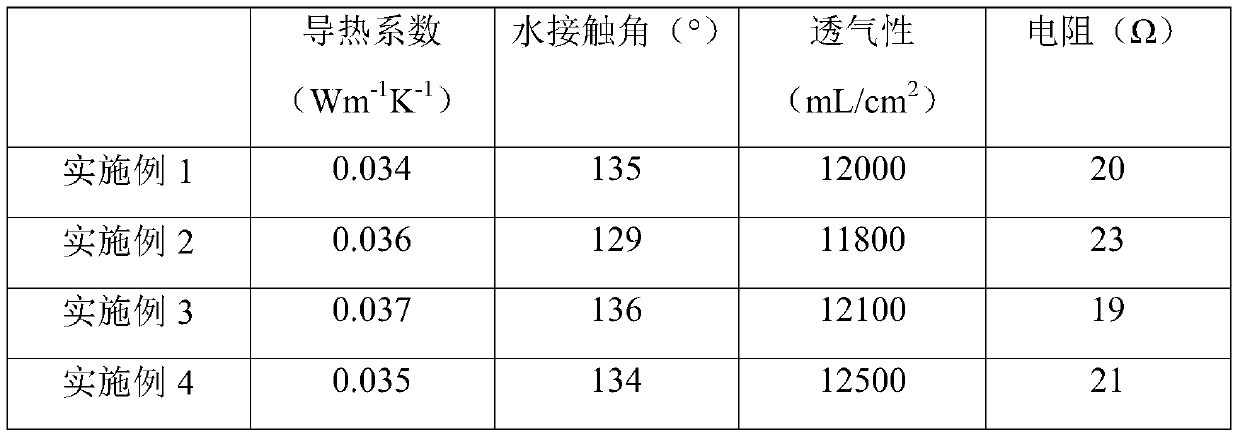

Embodiment 1

[0041] First prepare the bacterial cellulose porous material cross-linked by the silane coupling agent. The specific preparation process is as follows: take bacterial cellulose (Hainan Coco Food Co., Ltd.) with a length of 10 cm and a width of 5 cm and immerse it in 200 mL of NaOH solution with a concentration of 0.25 mol / L After heating at 80°C for 4 h, the bacterial cellulose was taken out and washed with deionized water until neutral. Afterwards, the bacterial cellulose was immersed in 200 mL of deionized water, heated at 80° C. for 4 h, and then the bacterial cellulose was taken out and washed 4 times with deionized water. The above-mentioned pretreatment process on the bacterial cellulose was repeated 7 times, and then the treated bacterial cellulose was shredded and stirred at a speed of 10000 r / min for 1 hour by a homogenizer to obtain a bacterial cellulose suspension. Finally, take 10 g of bacterial cellulose suspension, add 2 g of KH550, stir at room temperature for 2...

Embodiment 2

[0046] First prepare the bacterial cellulose porous material cross-linked by the silane coupling agent. The specific preparation process is as follows: take bacterial cellulose (Hainan Coco Food Co., Ltd.) with a length of 10 cm and a width of 5 cm and immerse it in 200 mL of NaOH solution with a concentration of 0.5 mol / L After heating at 100°C for 6 h, the bacterial cellulose was taken out and washed with deionized water until neutral. Afterwards, the bacterial cellulose was immersed in 200 mL of deionized water, heated at 100° C. for 6 h, and then the bacterial cellulose was taken out and washed 4 times with deionized water. The above-mentioned pretreatment process on the bacterial cellulose was repeated 10 times, and then the treated bacterial cellulose was shredded and stirred at a speed of 20000 r / min for 2 hours by a homogenizer to obtain a bacterial cellulose suspension. Finally, take 10g of bacterial cellulose suspension, add 4g of KH560, stir at room temperature for ...

Embodiment 3

[0051] First prepare the bacterial cellulose porous material cross-linked by the silane coupling agent. The specific preparation process is as follows: take bacterial cellulose (Hainan Coco Food Co., Ltd.) with a length of 10 cm and a width of 5 cm and immerse it in 200 mL of NaOH solution with a concentration of 0.4 mol / L After heating at 90°C for 5 h, the bacterial cellulose was taken out and washed with deionized water until neutral. Afterwards, the bacterial cellulose was immersed in 200 mL of deionized water, heated at 90° C. for 5 h, and then the bacterial cellulose was taken out and washed 4 times with deionized water. The above-mentioned pretreatment process on the bacterial cellulose was repeated 8 times, and then the treated bacterial cellulose was shredded and stirred at a speed of 15000 r / min for 2 hours by a homogenizer to obtain a bacterial cellulose suspension. Finally, take 10 g of bacterial cellulose suspension, add 3 g of A-151, stir at room temperature for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com