A kind of oil-pneumatic torsion spring

A torsion spring, oil and gas technology, applied in the direction of spring, spring/shock absorber, gas-liquid shock absorber, etc., can solve the problems of oil and gas mutual channeling, affecting the spring rebound effect, non-adjustment, etc., to enhance the compression resistance performance, The effect of prolonging the sealing period and preventing the mutual channeling of oil and gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

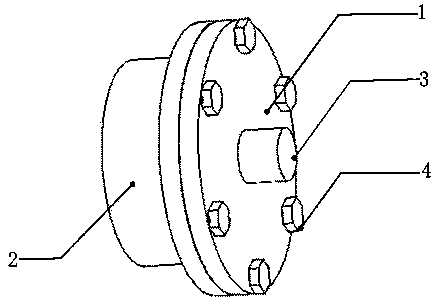

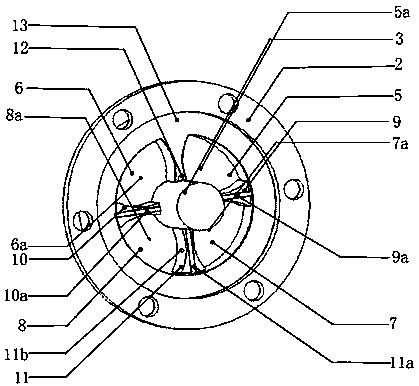

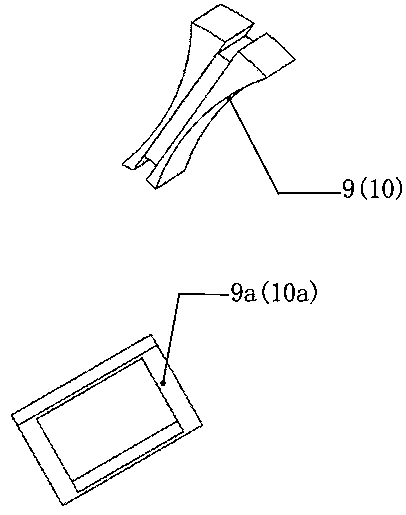

[0027] Such as Figure 1-7 As shown, an oil-pneumatic torsion spring includes a cylinder 2, a torsion shaft 3, a first floating piston 9, a second floating piston 10, and an end cover 1. One end of the torsion shaft 3 is designed with a counterbore, and the other end is designed with a torsion shaft swing arm. 11. A closed annular cavity is formed between the inner wall of the cylinder 2 and the outer wall of the torsion shaft 3. The annular cavity is divided into an air chamber and an oil chamber by the first floating piston 9 and the second floating piston 10. The baffle divides the air chamber into a symmetrical first air chamber 5 and a second air chamber 6, and the oil chamber is divided into a symmetrical first oil chamber 8 and a second oil chamber 9 by the swing arm 11 fixed on the torsion shaft 3 And it can be connected through the damping hole 11b provided on the swing arm, the damping hole 11b can make the hydraulic oil in the oil chamber spread in the two oil chamb...

Embodiment 2

[0038] Such as Figure 1-7 As shown, when assembling the oil and gas spring, it is necessary to apply sealant on each sealing ring, gasket, and sealing ring to improve its sealing effect. The addition of sealing layers in each sealing environment not only improves its sealing degree, but also prevents frequent pressure and The oil and gas crossover caused by the change can also reduce the working strength of the sealing ring, sealing gasket and sealing ring, and prolong their service life, thereby reducing the cost.

[0039] Such as Figure 1-7 As shown, after the assembly of the oil-gas spring, it is necessary to fill the oil-air chamber with oil and gas. At this time, it is necessary to ensure that the two air chambers are filled with the same amount of inert gas, because the amount of hydraulic oil in the two oil chambers is in a dynamic pressure balance. They can complement each other through damping holes, and the inert gas in the two gas chambers cannot change their res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com