Elevator system

A technology for elevators and elevator cars, which is applied to elevators, textile cables, hoisting devices, etc. in buildings. The effect of increased tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

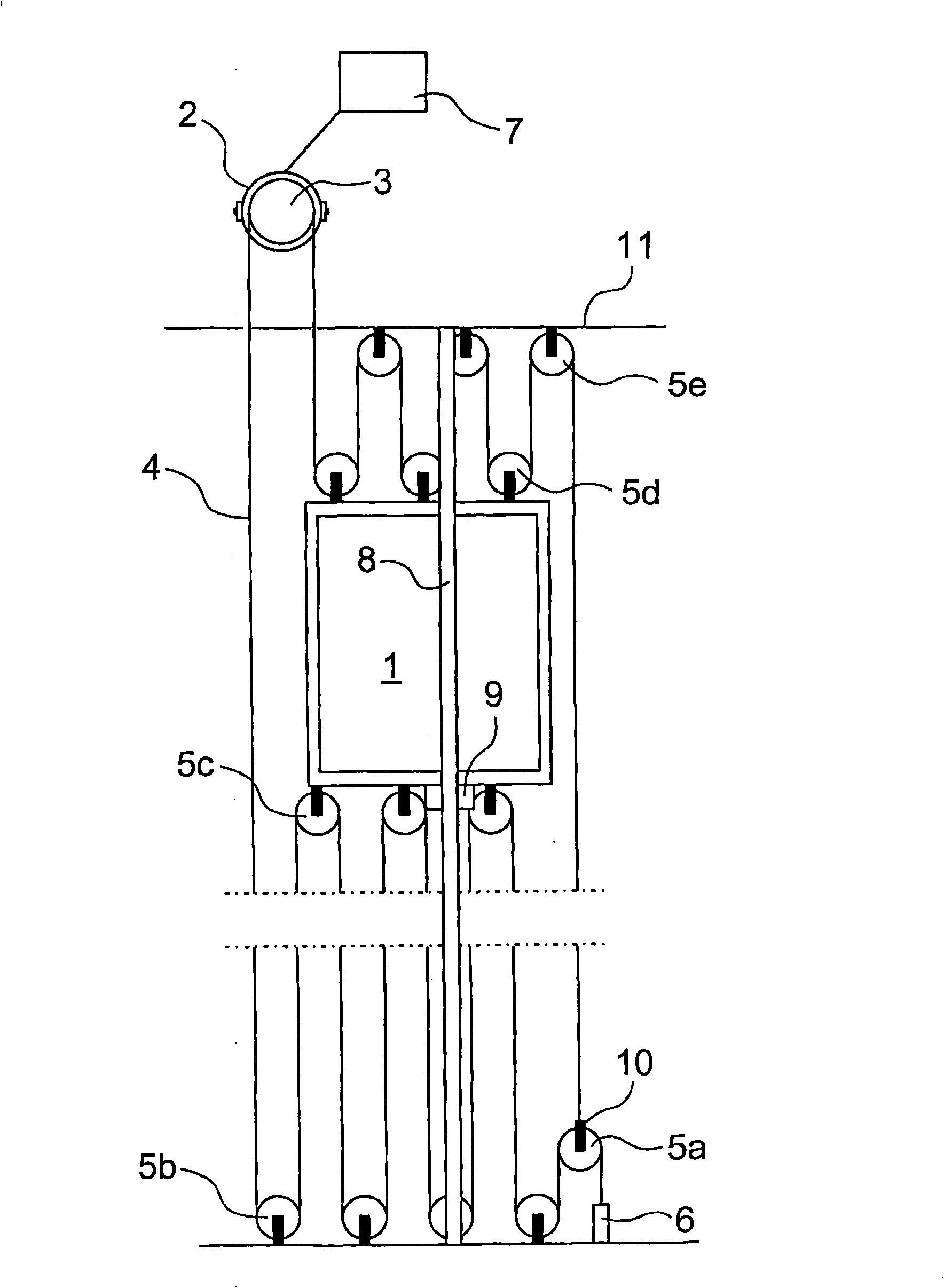

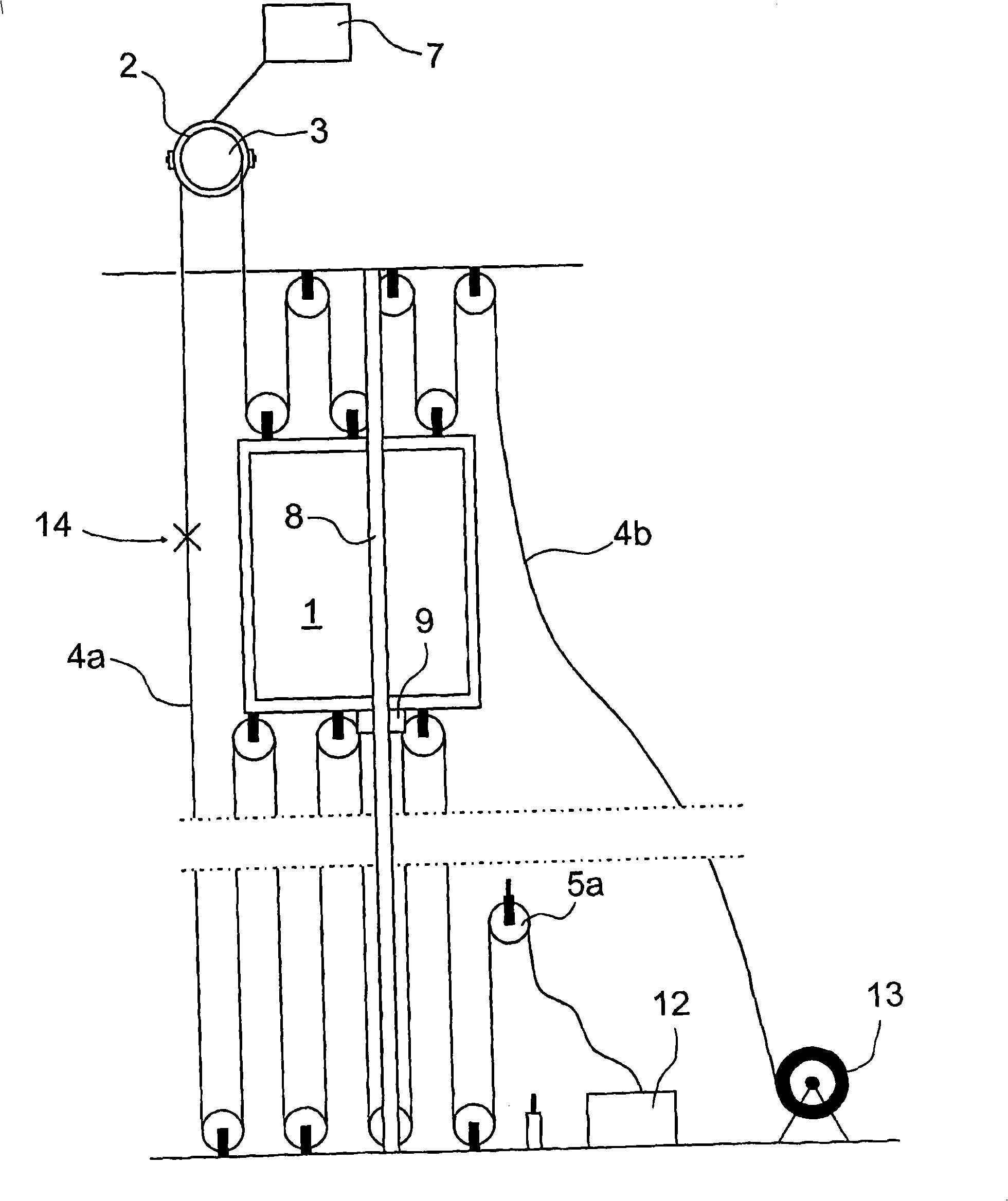

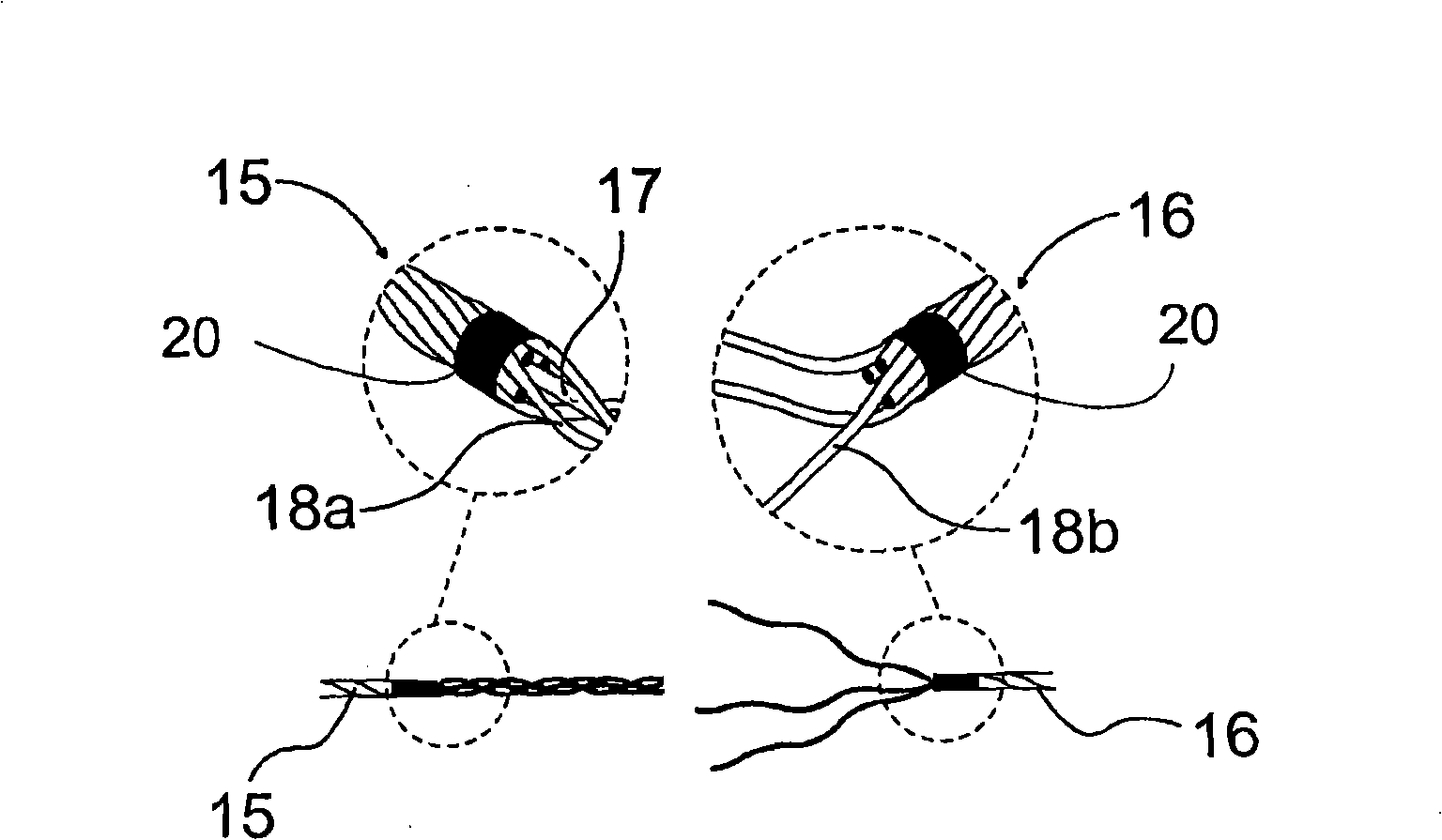

[0019] figure 1 shows a typical traction sheave elevator without counterweight provided with a set of ropes, such as traction rope 4, in which the method of the present invention for changing a set of traction ropes can be applied. The elevator car 1 is suspended by the set of hoisting ropes 4 and runs up and down in the elevator shaft along the guide rails 8 substantially in the vertical direction. The hoisting power of the elevator is provided by the traction machine 2, and the traction machine is connected to the control system 7 of the elevator. The first end of the set of traction ropes 4 is fixed to the anchor piece 6 fixed at the lower part of the elevator shaft, from which the traction ropes are guided, and first go around the ropes placed above the bottom of the elevator shaft from above Force compensation sheave 5a, then walk around the diverting pulley 5b that is installed at the bottom of the elevator hoistway from below, and the rope walks around the diverting pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com