A kind of polyaspartic acid compound and its preparation method and application

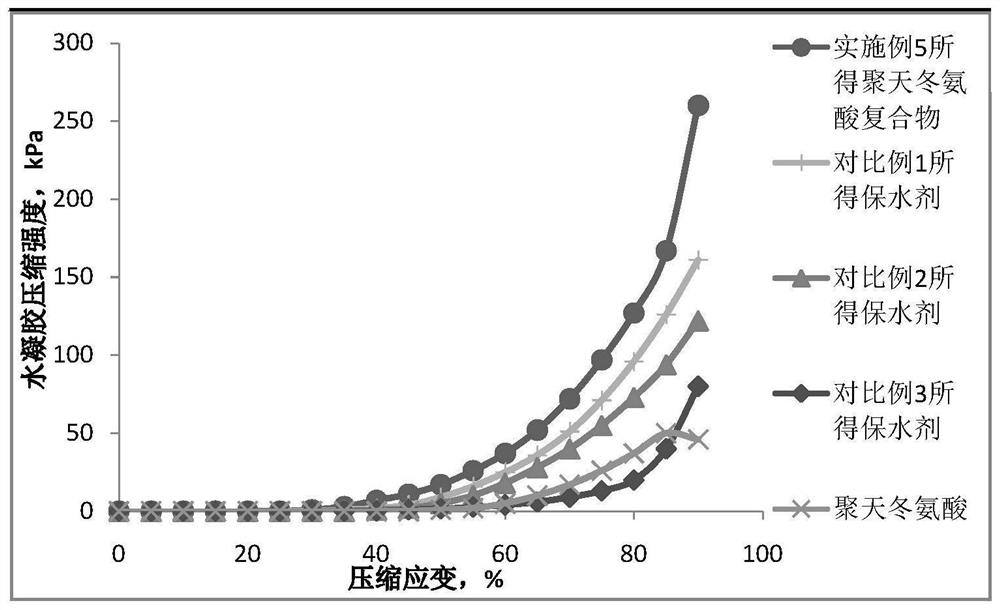

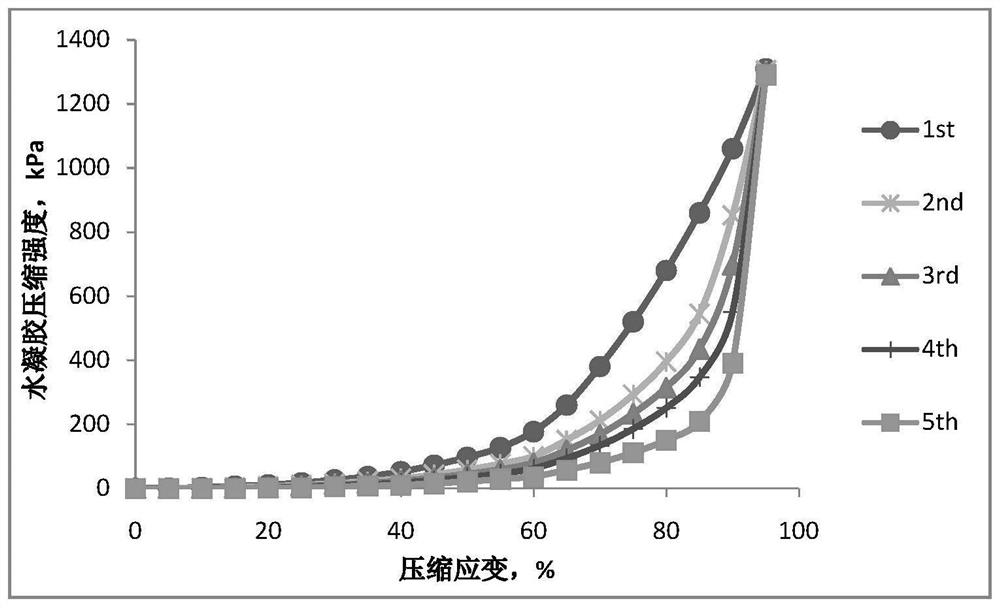

A polyaspartic acid and compound technology, which is applied in the agricultural field, can solve the problems of poor thermal stability, poor compression resistance, and low water retention effect of hydrogels, and achieves improved thermodynamic stability, excellent water release performance, and good effect. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of a polyaspartic acid complex, comprising the steps of:

[0023] S1. Dissolve 2kg of sodium hyaluronate in 80kg of water, adjust the pH of the system to 5.8-6.4 with 0.4mol / L hydrochloric acid, and add 2kg of carbodiimide and 0.2kg of N-hydroxysuccinimide in turn under stirring , add 1kgL-cysteine ethyl ester hydrochloride and stir for 5h to obtain prefabricated material;

[0024] S2. Mix 12kg polysuccinimide and 40kg sodium hydroxide solution with a concentration of 1.5mol / L, adjust the temperature to 55°C and stir for 50min, adjust the pH value of the system to 4.8-5.5 with a concentration of 68wt% phosphoric acid, and add 3kg of prefabricated material 1 kg of phenylacrylamide was stirred for 8 hours, 0.2 kg of ethylene glycol diglycidyl ether was added and reacted for 40 minutes at a reaction temperature of 60° C., precipitated with methanol, purified, and dried in vacuum to obtain a polyaspartic acid complex.

Embodiment 2

[0026] A preparation method of a polyaspartic acid complex, comprising the steps of:

[0027] S1. Dissolve 8kg of sodium hyaluronate in 50kg of water, adjust the pH of the system to 5.8-6.4 with 1.1mol / L hydrochloric acid, and add 1kg of carbodiimide and 0.8kg of N-hydroxysuccinimide in turn under stirring , add 0.5kgL-cysteine ethyl ester hydrochloride and stir for 10h to obtain prefabricated material;

[0028] S2. Mix 4kg of polysuccinimide and 60kg of 1mol / L sodium hydroxide solution, adjust the temperature to 65°C and stir for 30min, adjust the pH of the system to 4.8-5.5 with 77wt% phosphoric acid, add 1kg of prefabricated material, Stir 2kg of phenylacrylamide for 4 hours, add 0.8kg of ethylene glycol diglycidyl ether and react for 20 minutes at a reaction temperature of 70°C, precipitate with methanol, purify, and dry in vacuo to obtain a polyaspartic acid complex.

Embodiment 3

[0030] A preparation method of a polyaspartic acid complex, comprising the steps of:

[0031] S1. Dissolve 6kg of sodium hyaluronate in 60kg of water, adjust the pH of the system to 5.8-6.4 with 1mol / L hydrochloric acid, and add 1.3kg of carbodiimide and 0.6kg of N-hydroxysuccinimide in turn under stirring , add 0.6kgL-cysteine ethyl ester hydrochloride and stir for 8h to obtain prefabricated material;

[0032] S2. Mix 6kg polysuccinimide and 55kg sodium hydroxide solution with a concentration of 1.2mol / L, adjust the temperature to 62°C and stir for 35min, adjust the pH value of the system to 4.8-5.5 with a concentration of 76wt% phosphoric acid, add 1.5kg prefabricated 1.7kg of phenylacrylamide was stirred for 5 hours, and 0.6kg of ethylene glycol diglycidyl ether was added to react for 25 minutes at a reaction temperature of 66°C. Precipitate with methanol, purify, and dry in vacuo to obtain a polyaspartic acid complex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com