Compression-resistant polyurethane foam and preparation method thereof

A polyurethane foam, polyurethane technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve problems such as restricting the compression performance of foam materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

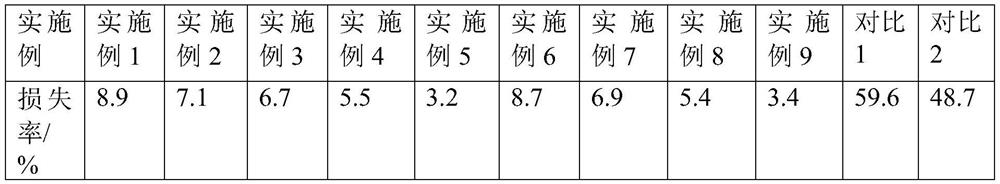

Examples

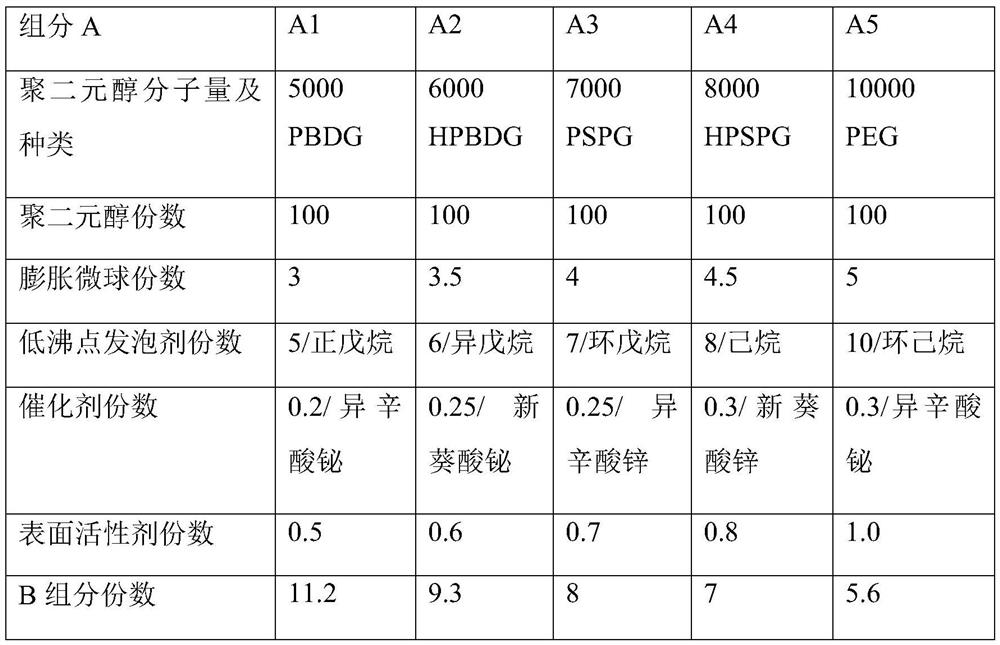

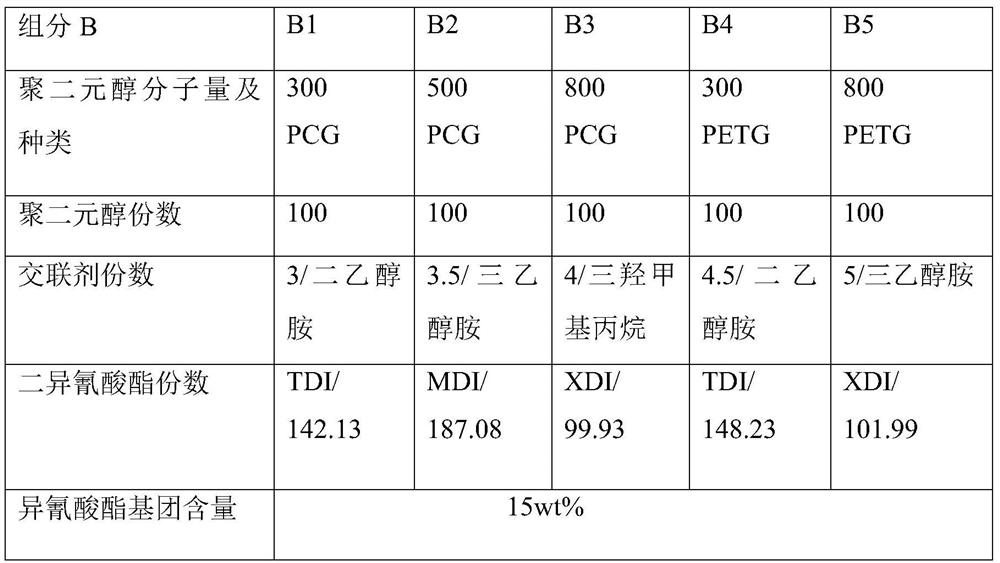

Embodiment 1

[0029] This embodiment is a combination of A1 and B1, wherein component A includes: 100 parts of polybutadiene diol with a molecular weight of 5000, 3 parts of expanded microspheres, 5 parts of n-pentane, 0.2 parts of bismuth isooctanoate, polysiloxane 0.5 parts of alkane; component B includes 100 parts of polycarbonate diol with a molecular weight of 300, 3 parts of diethanolamine, 142.13 parts of toluene diisocyanate, and the content of isocyanate groups is 15 wt%. Mix component A and component B separately, and take 11.2 parts of component B and mix it with the above component A; then apply it on the surface of PET film according to the coating thickness of 0.1mm, and heat and cure it at a temperature of 115°C for 20 minutes to obtain Polyurethane foam.

Embodiment 2

[0031]The present embodiment is a combination of A2 and B2, wherein component A includes: 100 parts of hydrogenated polybutadiene diol with a molecular weight of 6000, 3.5 parts of expanded microspheres, 6 parts of isopentane, 0.25 parts of bismuth neodecanoate, poly 0.6 parts of siloxane; component B includes 100 parts of polycarbonate diol with a molecular weight of 500, 3.5 parts of triethanolamine, 187.08 parts of diphenylmethane diisocyanate, and the content of isocyanate groups is 15 wt%. Mix component A and component B separately, and take 9.3 parts of component B and mix it with the above component A; then apply it on the surface of PBT film according to the coating thickness of 0.2mm, heat and cure at a temperature of 116°C for 19min, and obtain Polyurethane foam.

Embodiment 3

[0033] This embodiment is a combination of A3 and B3, wherein component A includes: 100 parts of polyisoprene diol with a molecular weight of 7000, 4 parts of expanded microspheres, 7 parts of cyclopentane, 0.25 parts of zinc isooctanoate, polysilicon 0.7 parts of oxane; component B includes 100 parts of polycarbonate diol with a molecular weight of 800, 4 parts of trimethylolpropane, 99.93 parts of xylylene diisocyanate, and the content of isocyanate groups is 15 wt%. Mix component A and component B separately, and take 8 parts of component B and mix it with the above component A; then apply it on the surface of the PC film according to the coating thickness of 0.3 mm, heat and cure at a temperature of 117 ° C for 18 minutes, and obtain Polyurethane foam.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com