Graphene-based organosilicon porous nanometer material and preparation method thereof

A graphene-based, nano-material technology, applied in the field of organic silicon materials, can solve the problems of poor compatibility between graphene and organic silicon, easy agglomeration of graphene, graphene structure and intrinsic defects, etc., and achieve fine and uniform cross-sectional cells , Adhesive substrate firm, excellent impact resistance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Example 1: A graphene-based organosilicon porous nanomaterial and its preparation method

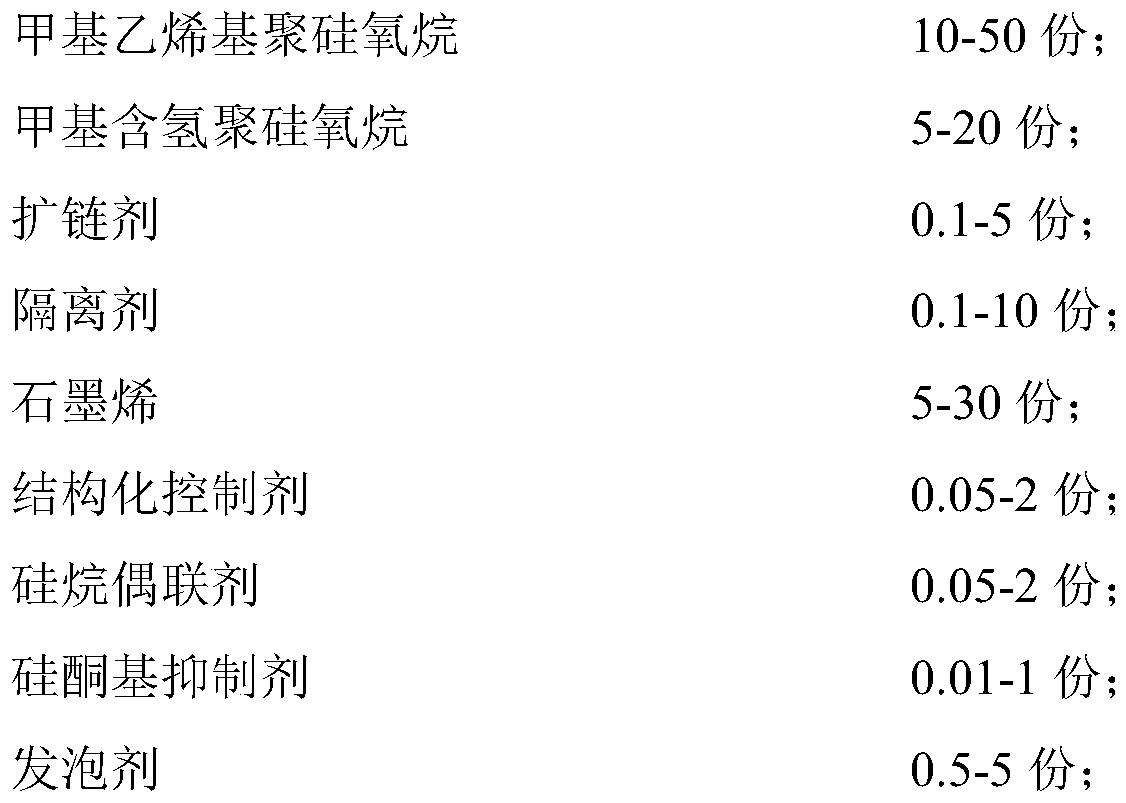

[0048] A graphene-based organosilicon porous nanomaterial, consisting of component A and component B at a weight ratio of 1.5:1. The component A includes the following raw materials and parts by weight: methyl vinyl polysiloxane 30 12.5 parts of methyl hydrogen polysiloxane; 2.55 parts of chain extender; 5 parts of release agent; 18 parts of graphene; 1 part of structure control agent; 1 part of silane coupling agent; 0.5 parts of silicone-based inhibitor ; 2.6 parts of blowing agent.

[0049] The component B includes the following raw materials and parts by weight: 15 parts of methyl vinyl polysiloxane; 20 parts of methyl vinyl MQ silicone resin; 5 parts of release agent; 18 parts of graphene; parts; 0.5 parts of catalyst; 2.75 parts of activator.

[0050] The preferred technical solution is: the methyl vinyl polysiloxane is at least one of the compounds of general formula A, g...

Embodiment 2

[0084] Example 2: A graphene-based organic silicon porous nanomaterial and its preparation method

[0085] A graphene-based organosilicon porous nanomaterial is composed of component A and component B mixed in a mass ratio of 1:1;

[0086] The component A includes the following raw materials in parts by weight:

[0087]

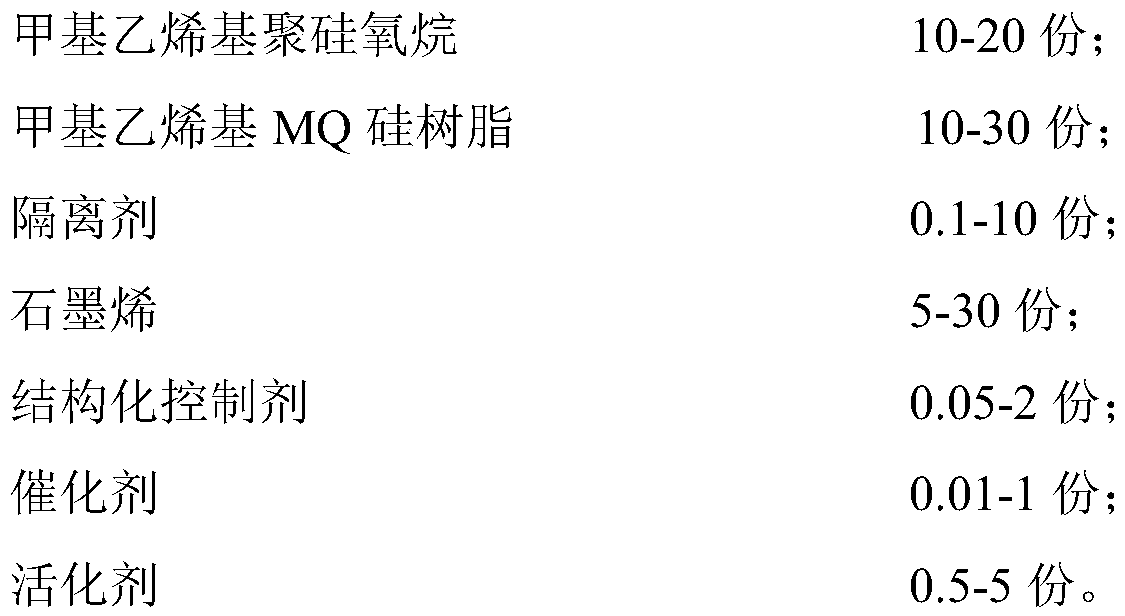

[0088] The component B includes the following raw materials in parts by weight:

[0089]

[0090] The preferred technical scheme is: the methyl vinyl polysiloxane is a compound that meets the general formula A:

[0091] (ViMe 2 SiO 1 / 2 ) (MeSiO 3 / 2 )a general formula A;

[0092] Where Me is a methyl group, Vi is a vinyl group, a=2, and at 25° C., the kinematic viscosity of the compound conforming to the general formula A is 8000 centipoise, and the mass fraction of the vinyl functional group is 0.02%.

[0093] The preferred technical solution is: the methyl hydrogen-containing polysiloxane is a compound conforming to the general formula D:

[009...

Embodiment 3

[0117] Example 3: A graphene-based organic silicon porous nanomaterial and its preparation method

[0118] A graphene-based organosilicon porous nanomaterial, which is composed of component A and component B mixed in a mass ratio of 2:1;

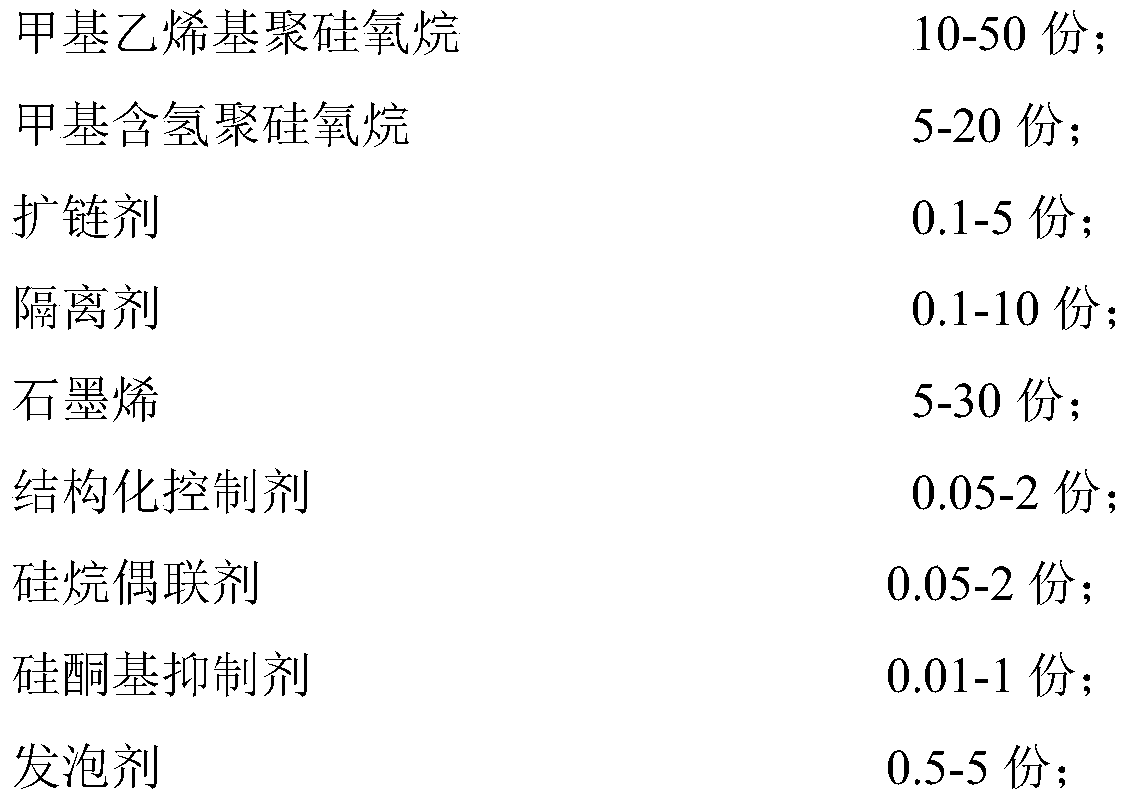

[0119] The component A includes the following raw materials in parts by weight:

[0120]

[0121]

[0122] The component B includes the following raw materials in parts by weight:

[0123]

[0124] The preferred technical solution is: the methyl vinyl polysiloxane is a mixture of compounds conforming to general formula A, general formula B and general formula C in a mass ratio of 1:1:1:

[0125] (ViMe 2 SiO 1 / 2 ) (MeSiO 3 / 2 )a general formula A;

[0126] Wherein Me is a methyl group, Vi is a vinyl group, a=5, and at 25°C, the kinematic viscosity of the compound conforming to the general formula A is 10000 centipoise, and the mass fraction of the vinyl functional group is 1%;

[0127] (ViMe2SiO 1 / 2 )(Me 2 SiO)b(MeSiO 3 / 2 )c ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com