Organosilicon porous breathable disinfection and sterilization nano-filtration material for masks and preparation method thereof

A sterilization and nanofiltration technology, applied in filtration and separation, membrane filters, separation methods, etc., can solve the problems of low air permeability, not suitable for patients with respiratory diseases, and the filtration efficiency cannot reach 100%, and achieve high gas permeability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: A kind of organosilicon porous air-permeable disinfection and sterilization nano-filter material for mask and its preparation method

[0054] A kind of organosilicon porous air-permeable disinfection and sterilization nano filter material for masks, which is synthesized by component A and component B with the same mass ratio; the component A includes the following components: methyl vinyl polysiloxane, formazan Hydrogen-containing polysiloxane, chain extender, foaming agent, tackifier, acetylenic alcohol inhibitor and disinfectant, wherein the weight percentage of each component is as follows: methyl vinyl polysiloxane 30%, methyl Hydrogen-containing polysiloxane 56.95%, chain extender 5%, foaming agent 5%, tackifier 0.5%, acetylenic alcohol inhibitor 0.05% and disinfectant 2.5%;

[0055] The component B includes the following components: methyl vinyl polysiloxane, anti-structuring agent, weak reinforcing agent, foam stabilizer and platinum catalyst, where...

Embodiment 2

[0087] Embodiment 2: A kind of organosilicon porous air-permeable disinfection and sterilization nano-filter material for mask and its preparation method

[0088] A kind of organosilicon porous air-permeable disinfection and sterilization nano filter material for masks, the raw material formula includes component A and component B:

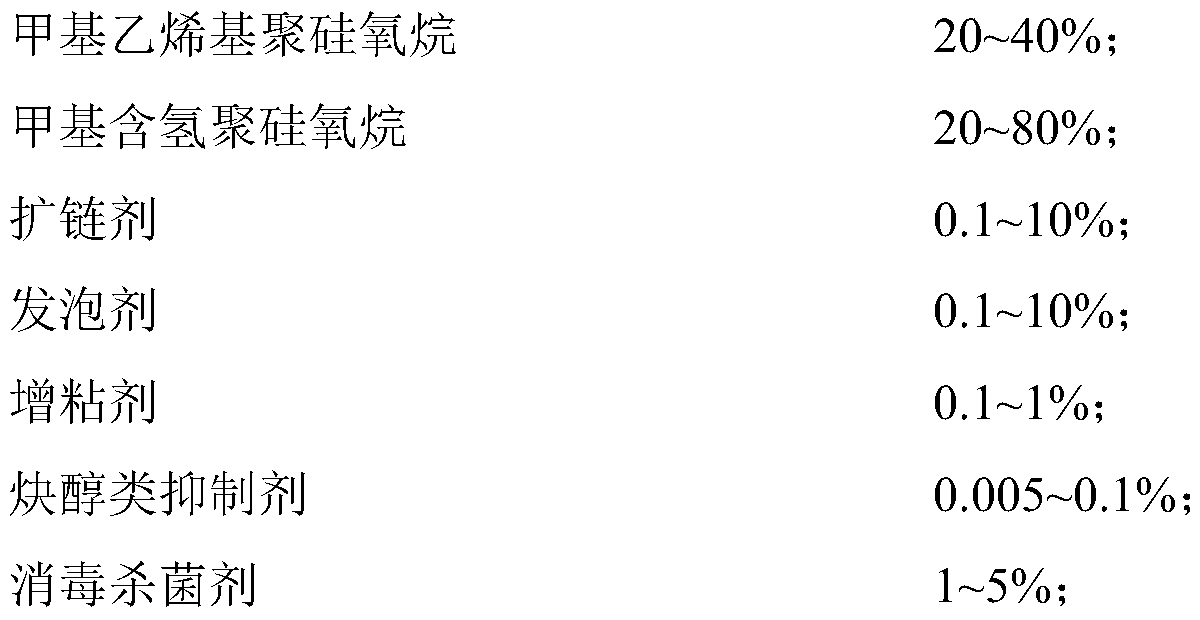

[0089] Described component A comprises the material of following mass percentage:

[0090]

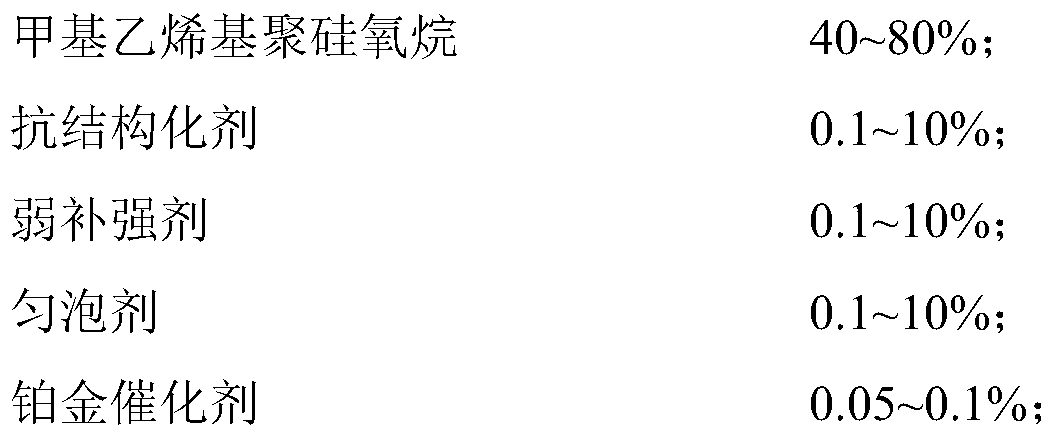

[0091] Described component B comprises the following mass percentage material:

[0092]

[0093] The mass ratio between the component A and the component B is 1:1.

[0094] The preferred technical solution is: the methyl vinyl polysiloxane is a mixture of compounds conforming to the general formula B and the general formula D according to the mass ratio of 1:1:

[0095] (ViMe 2 SiO 1 / 2 )(Me 2 SiO) m (MeSiO 3 / 2 ) n Formula B;

[0096] Wherein, Me is a methyl group, Vi is a vinyl group; m / n=1; at 25°C, the kinemati...

Embodiment 3

[0121] Embodiment 3: A kind of organosilicon porous air-permeable disinfection and sterilization nano-filter material for masks and its preparation method

[0122] A kind of organosilicon porous air-permeable disinfection and sterilization nano filter material for masks, the raw material formula includes component A and component B:

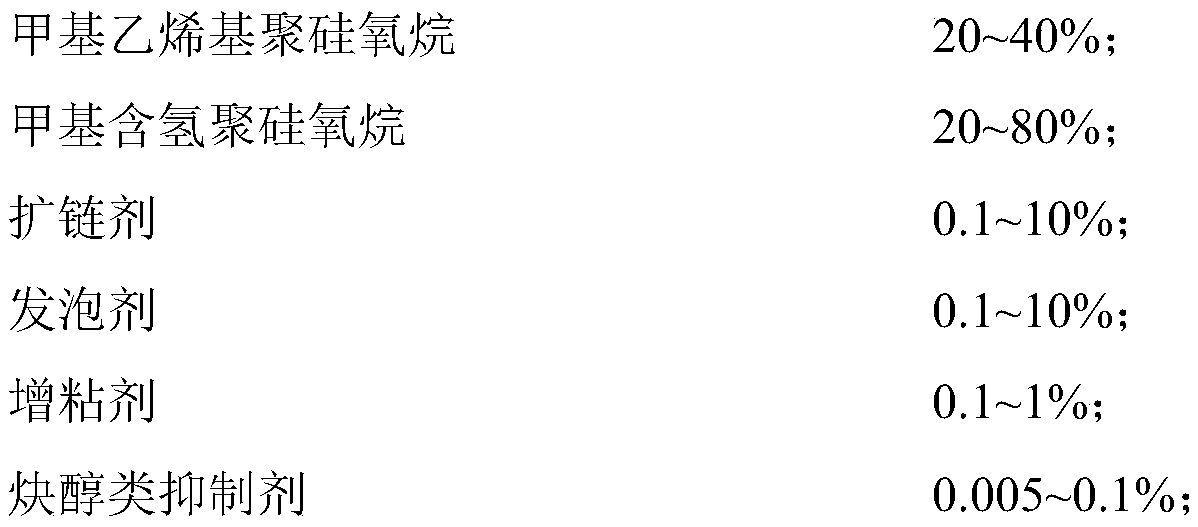

[0123] Described component A comprises the material of following mass percentage:

[0124]

[0125]

[0126] Described component B comprises the following mass percentage material:

[0127]

[0128] The mass ratio between the component A and the component B is 0.8:1.

[0129] A preferred embodiment is: the methyl vinyl polysiloxane is a compound conforming to the general formula A:

[0130] [(CH 3 ) 2 (CH 2 =CH)SiO 1 / 2 ] a [(CH 3 ) 3 SiO 1 / 2 ] b [SiO 4 / 2 ] c Formula A;

[0131] Among them, [(CH3)2(CH2=CH)SiO1 / 2] a [CH3)3SiO1 / 2] b It is an M structure, [SiO4 / 2]c is a Q structure, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com