Minisize solid silicon needle array chip and its preparation method and use

A needle array, solid technology, applied in the direction of microneedles, needles, other medical devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

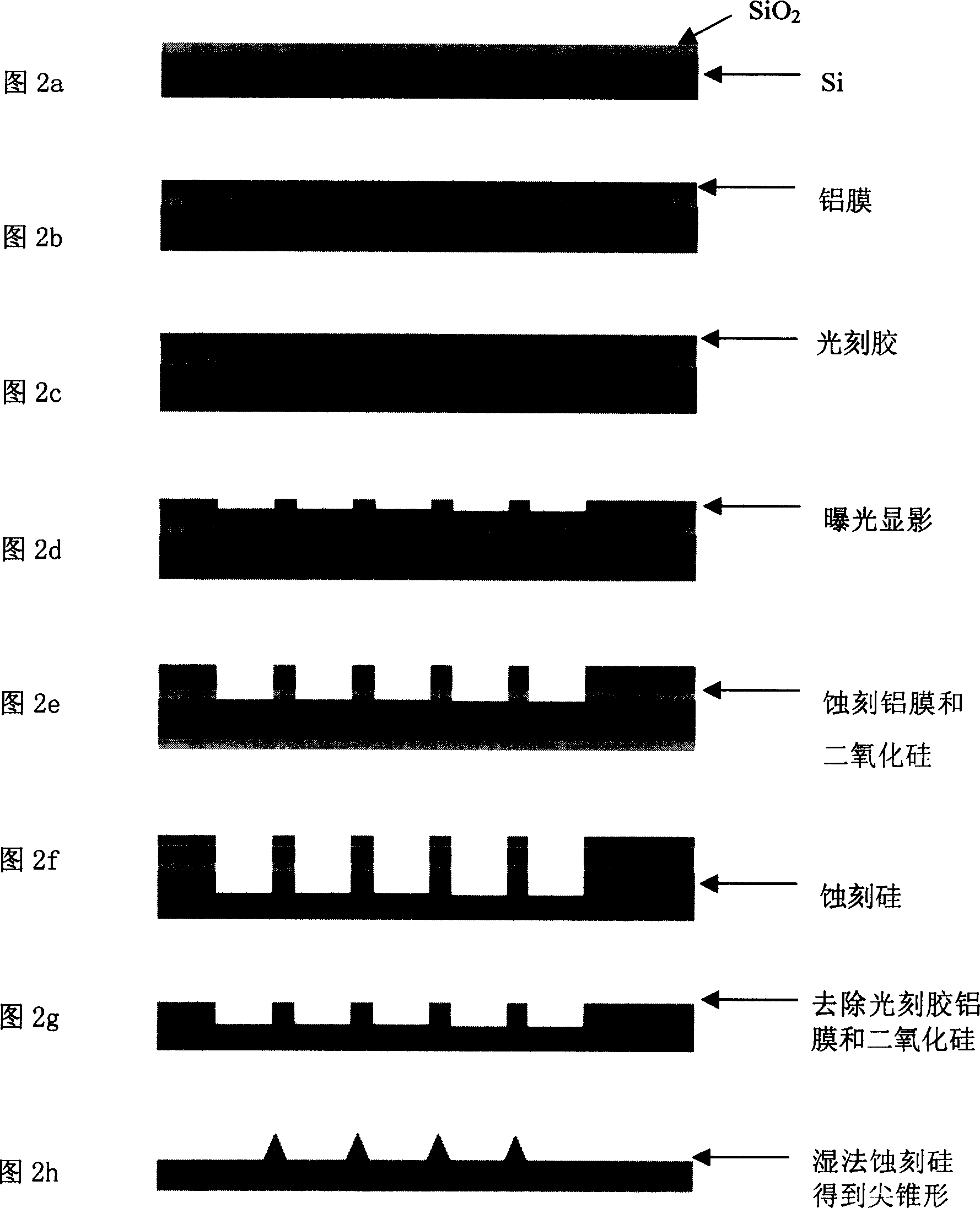

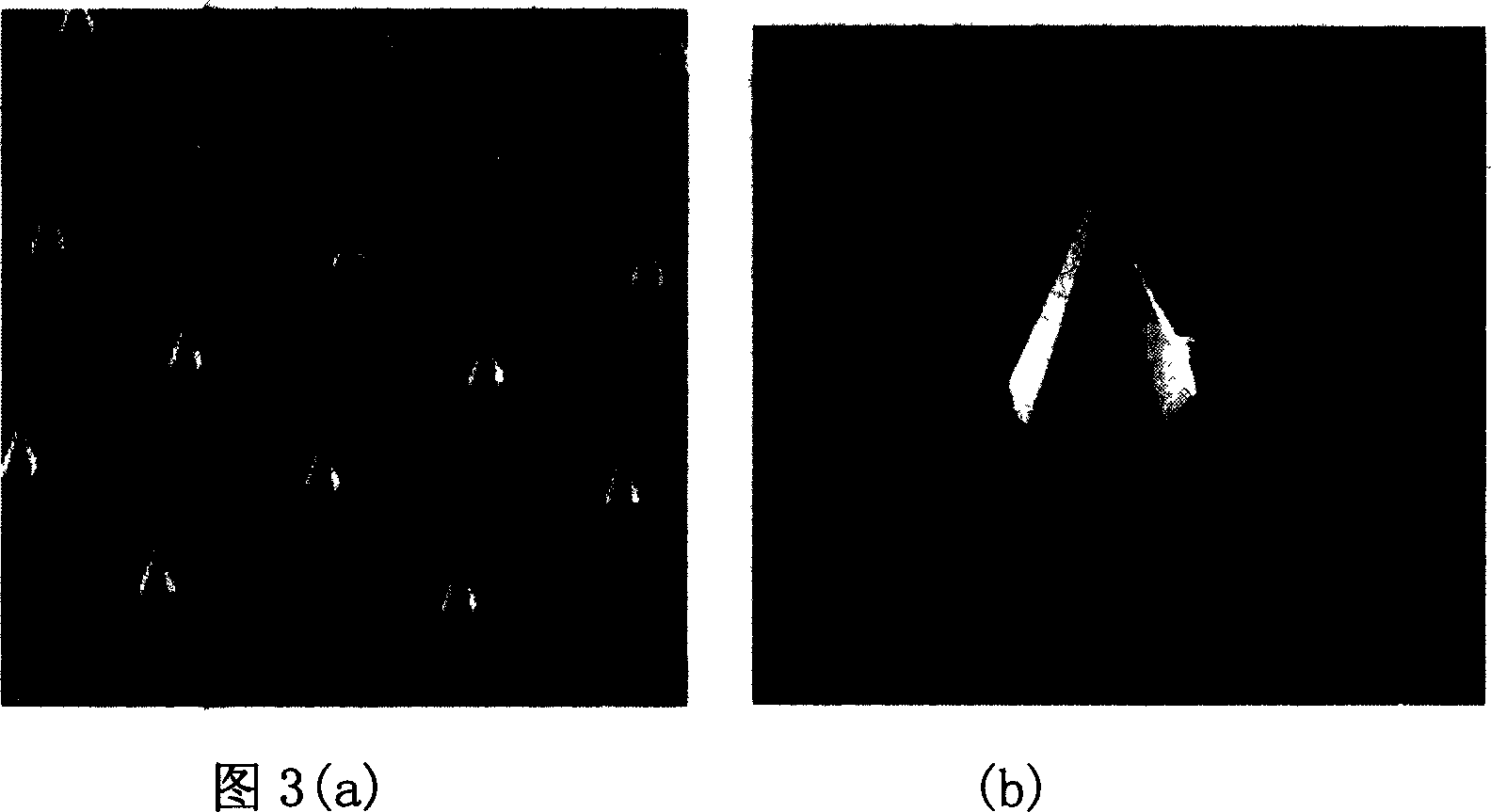

[0084] Embodiment 1: the making of tapered micro-silicon needle

[0085] Basic process flow: Single-sided polishing of single crystal silicon wafer → growth of a layer of SiO 2 →Deposit metal film→Glue coating→Photolithography to obtain solid microneedle pattern→Reactive ion etching (RIE) removes metal film and SiO not protected by photoresist 2 Partial→anisotropic deep reactive ion etching (DRIE) to obtain microcylindrical arrays→wet etching to obtain solid microneedles.

[0086] Single-sided polished single crystal silicon type, 500 microns thick as raw material. The monocrystalline silicon was first cleaned with a cleaning solution containing 5 parts of deionized water, 1 part of 30wt% hydrogen peroxide and 1 part of 30wt% ammonia water at a temperature close to 80 degrees, and then dried at 150 degrees for 10 minutes. A silicon dioxide layer with a thickness of about 1 micron is grown on both sides of the single crystal silicon type through thermal oxidation at 900-11...

Embodiment 2

[0087] Embodiment 2: the making of nail type miniature solid silicon needle

[0088] Single-sided polished single crystal silicon type, 500 microns thick as raw material. The monocrystalline silicon was first cleaned with a cleaning solution containing 5 parts of deionized water, 1 part of 30wt% hydrogen peroxide and 1 part of 30wt% ammonia water at a temperature close to 80 degrees, and then dried at 150 degrees for 10 minutes. A silicon dioxide layer with a thickness of about 1.5 microns is grown and formed on the surface of single crystal silicon through high temperature thermal oxidation at 900-1100 ° C; a uniform layer of 1-2 microns is coated on the silicon dioxide film by the spin coating method Thick Shipley 1818 photoresist, pre-baked (soft baked) at 90 degrees for 5 minutes, formed a 80×80 array in a unit of 1 square centimeter, with a diameter of 100 microns and a solid circle mask with a pitch of 200 microns film (quartz glass is used in the semiconductor standa...

Embodiment 3

[0089] Embodiment 3: the making of tapered micro-silicon needle

[0090] Basic process flow: Double-sided polishing of single crystal silicon wafer → growth of a layer of SiO 2 →Deposit metal film→Glue coating→Photolithography to obtain solid microneedle pattern→Hydrochloric acid solution and a mixture of ammonium fluoride and hydrofluoric acid to remove the metal film and SiO not protected by photoresist 2 Partial→anisotropic deep reactive ion etching (DRIE) to obtain microcylindrical arrays→wet etching to obtain solid microneedles.

[0091] Double-sided polished single crystal silicon type, 500 microns thick as raw material. The single crystal silicon is first cleaned with a cleaning solution containing 5 parts of deionized water, 1 part of 30wt% hydrogen peroxide and 1 part of 30wt% ammonia water at a temperature close to 80 degrees, and then dried at 120 degrees for 10 minutes. A silicon dioxide layer with a thickness of about 1 micron is grown on both sides of the sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com