Process and equipment for removing CO2 in flue gas by utilizing amine solid adsorbent

A solid adsorbent, CO2 technology, applied in the direction of adsorption, reagents, petroleum industry, etc., can solve the problems of lack of amine solid adsorbent, no process and equipment involved in removal, etc., to achieve low investment and operating costs, improve Absorption amount and absorption rate, the effect of increasing amine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

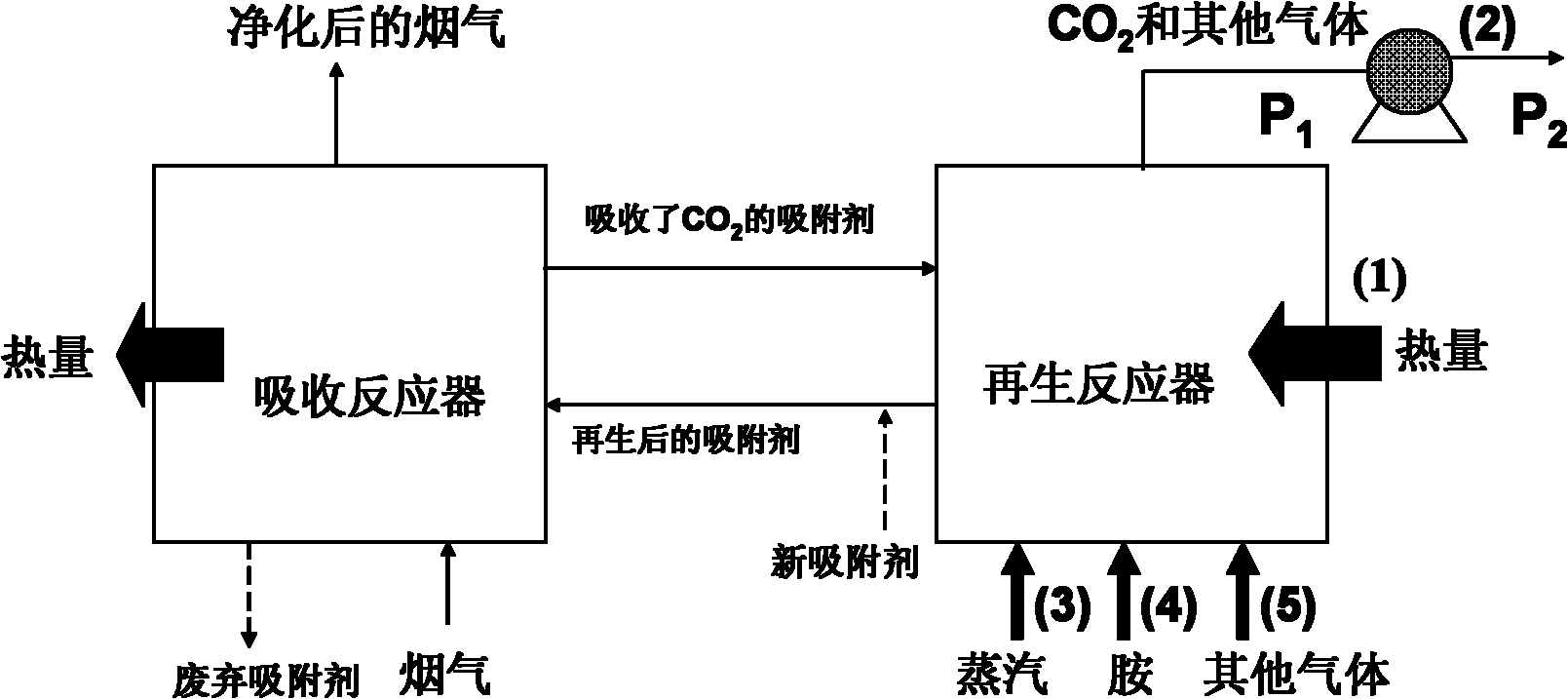

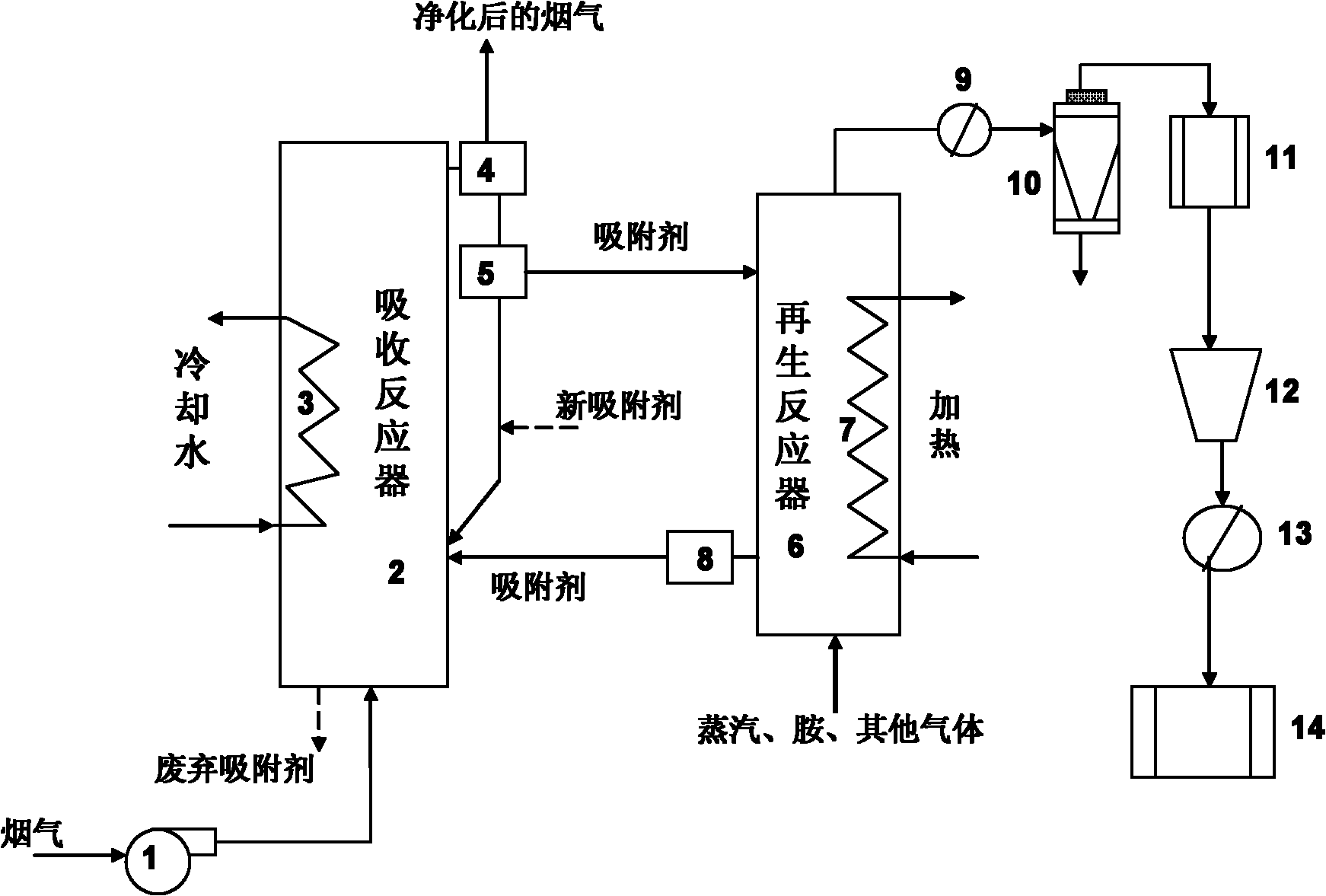

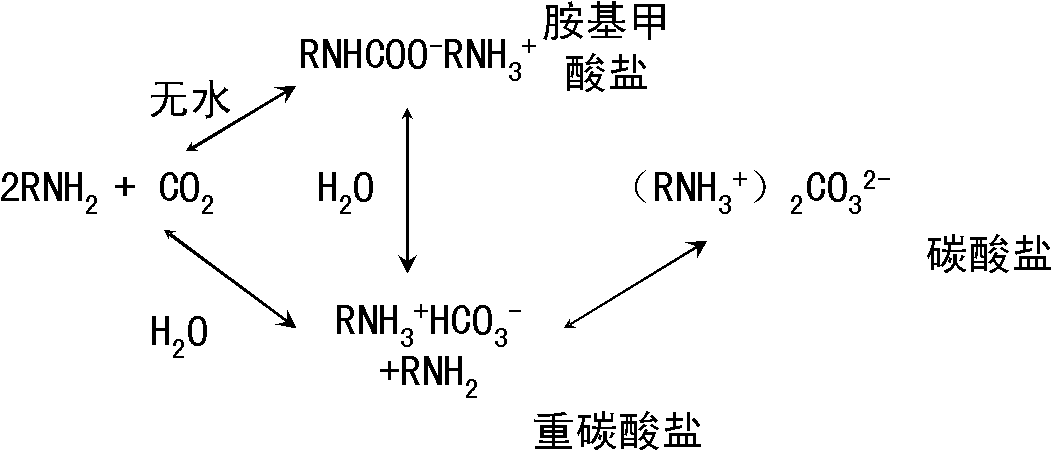

[0033] Firstly, the flue gas after denitrification, dust removal and desulfurization is pressurized by the booster fan, and then enters the absorption reactor containing amine solid adsorbent, and the CO in the flue gas 2 Adsorbed by amine solid adsorbent, the resulting clean flue gas is discharged into the atmosphere. absorbed CO 2 The amine solid adsorbent enters the regeneration reactor for regeneration treatment. The reasonable regeneration method is to remove CO from flue gas by amine solid adsorbent. 2 The key to technology. The regeneration method can have the following options, as attached figure 1 shown. (1) Thermal regeneration. Provide heat to the regeneration reactor to increase the temperature of the regeneration reactor, so that the temperature of the regeneration reactor is higher than that of the absorption reactor, so that the CO adsorbed by the amine solid adsorbent 2 It can be effectively desorbed, so that the amine solid adsorbent can be reused. (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com