Non-aqueous decarburization solution for capturing carbon dioxide in mixed gas and application thereof

A carbon dioxide and mixed gas technology, which is applied in air quality improvement, chemical instruments and methods, and dispersed particle separation, can solve the problems of low decarbonization capacity and high regeneration energy consumption, and achieve low regeneration energy consumption, fast mass transfer, and high viscosity small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

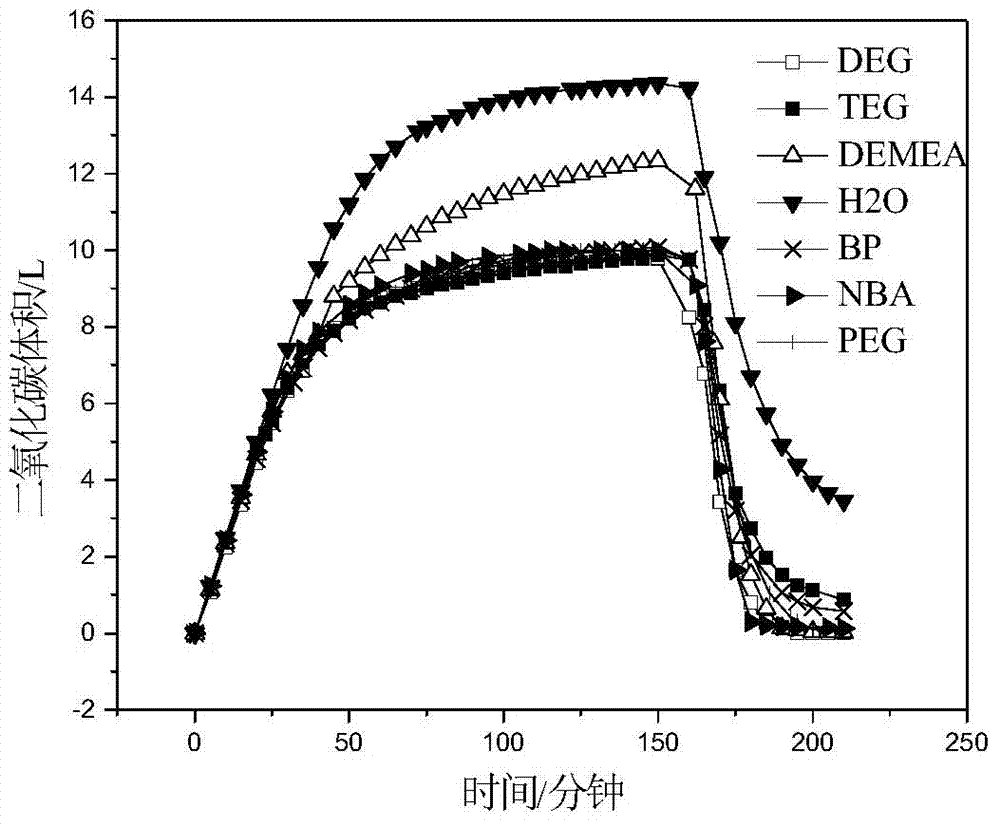

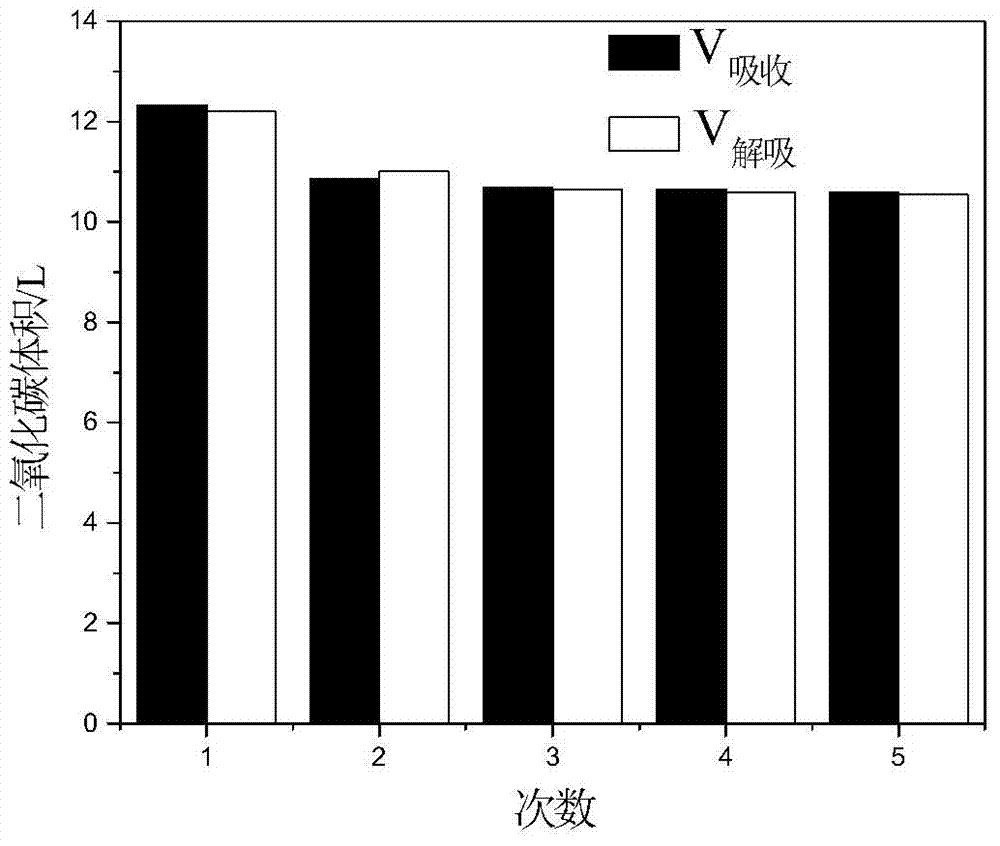

Embodiment 1

[0047] With 200g non-aqueous decarburization solution as absorption solution, pack in the reactor that is furnished with constant temperature oil bath stirrer of 500ml (experimental apparatus sees Figure 5 ), wherein the mass fraction of EMEA is 40%, and DEMEA is as a solvent, and its mass fraction is 60%. At a temperature of 40°C, at a flow rate of 250ml / min, CO with a pressure of 0.2MPa and a concentration of 99.995% was introduced. 2 , Use a wet anti-corrosion flowmeter for continuous measurement, and thus calculate the absorption rate and amount of carbon dioxide. After the solution reaches saturation, set the temperature of the oil bath to 120°C for desorption, and measure the desorption amount and desorption rate for 60 minutes. After five absorption and desorption tests, check its stability (see figure 1 and 3 ).

Embodiment 2

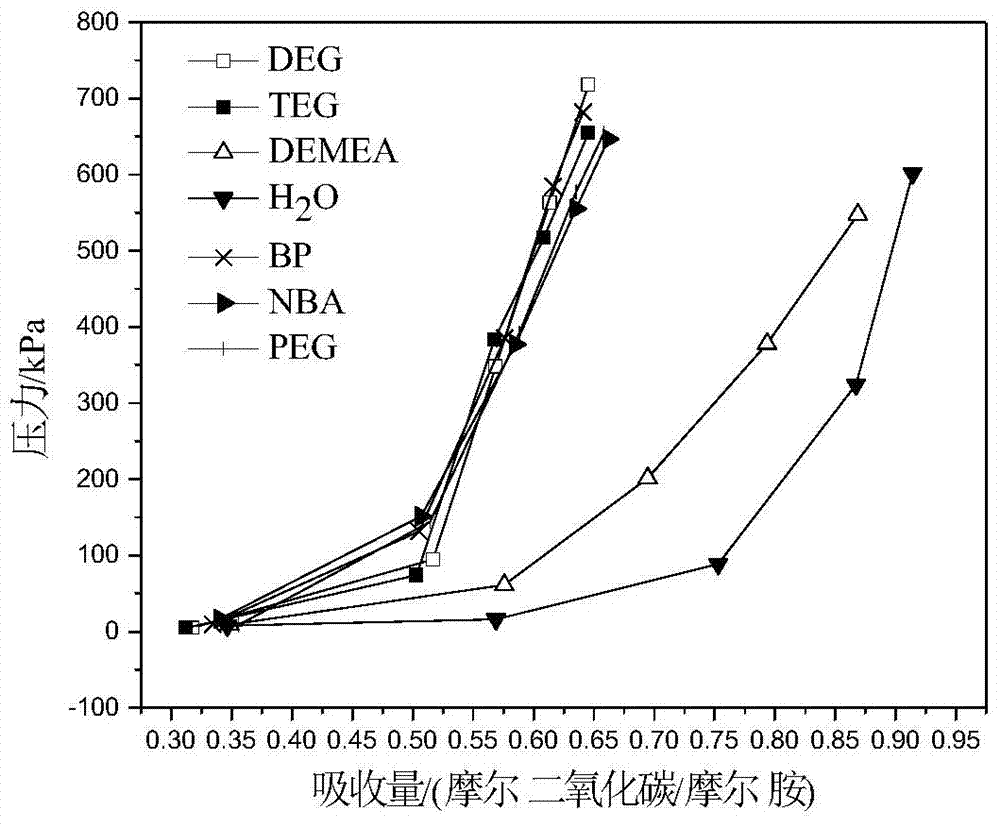

[0049] 200g of non-aqueous decarburization solution is used as the absorption solution, and the filling volume is 1105cm 3 Vacuum the stainless steel reactor. Another gas storage tank has a volume of 1290cm 3 , the reactor and the storage tank are all placed in a water bath to keep the temperature at 40°C, and the equilibrium temperature and pressure in the reactor and storage tank are measured by a K-type thermocouple and a pressure sensor (for the experimental device, see Figure 6 ).

[0050] As can be seen from the examples, in the case of non-water, the solution absorption decreases slightly, but the desorption rate is fast. When the saturated carbon dioxide absorption solution is desorbed at 120 ° C, the desorption rate decreases with the increase of the reaction time. Moreover, after five times of absorption and desorption, the absorption and desorption amounts are similar and stable, and can be applied industrially.

[0051] In summary, the non-aqueous decarburizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com