Absorbent cores with improved intake performance

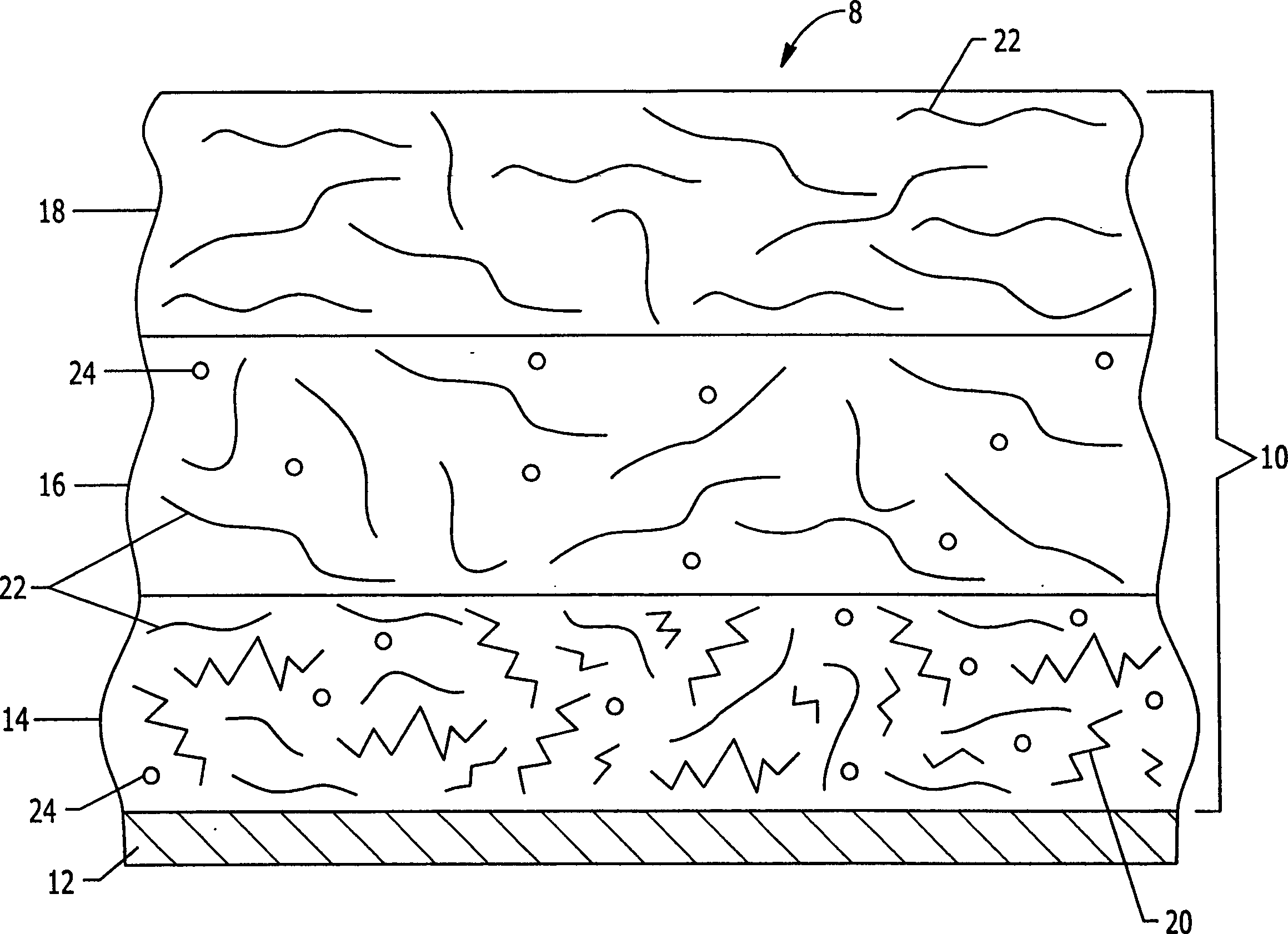

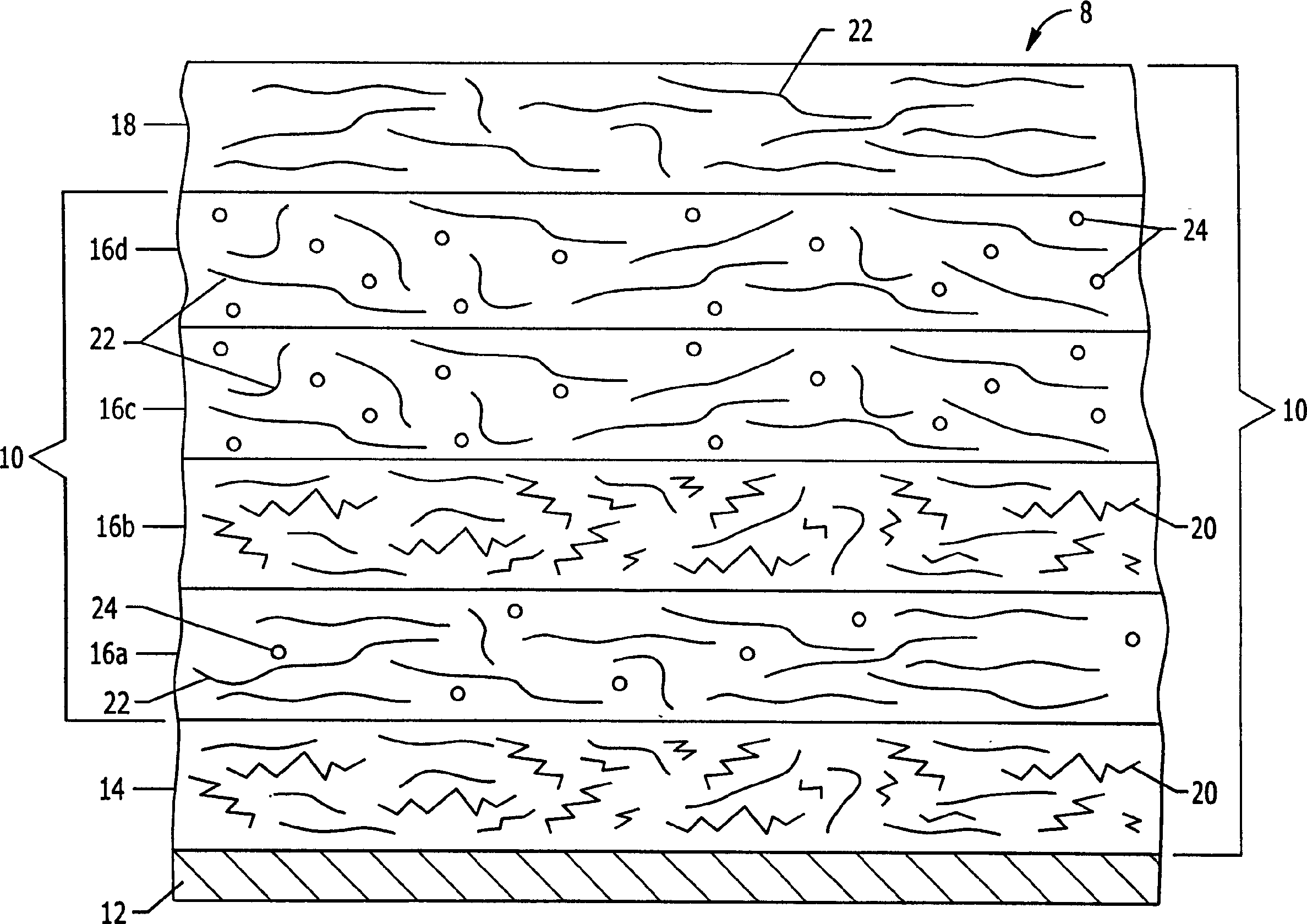

An absorbent core and super absorbent technology, applied in absorbent pads, medical science, bandages, etc., which can solve the problems of complex structure and increased cost of final products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

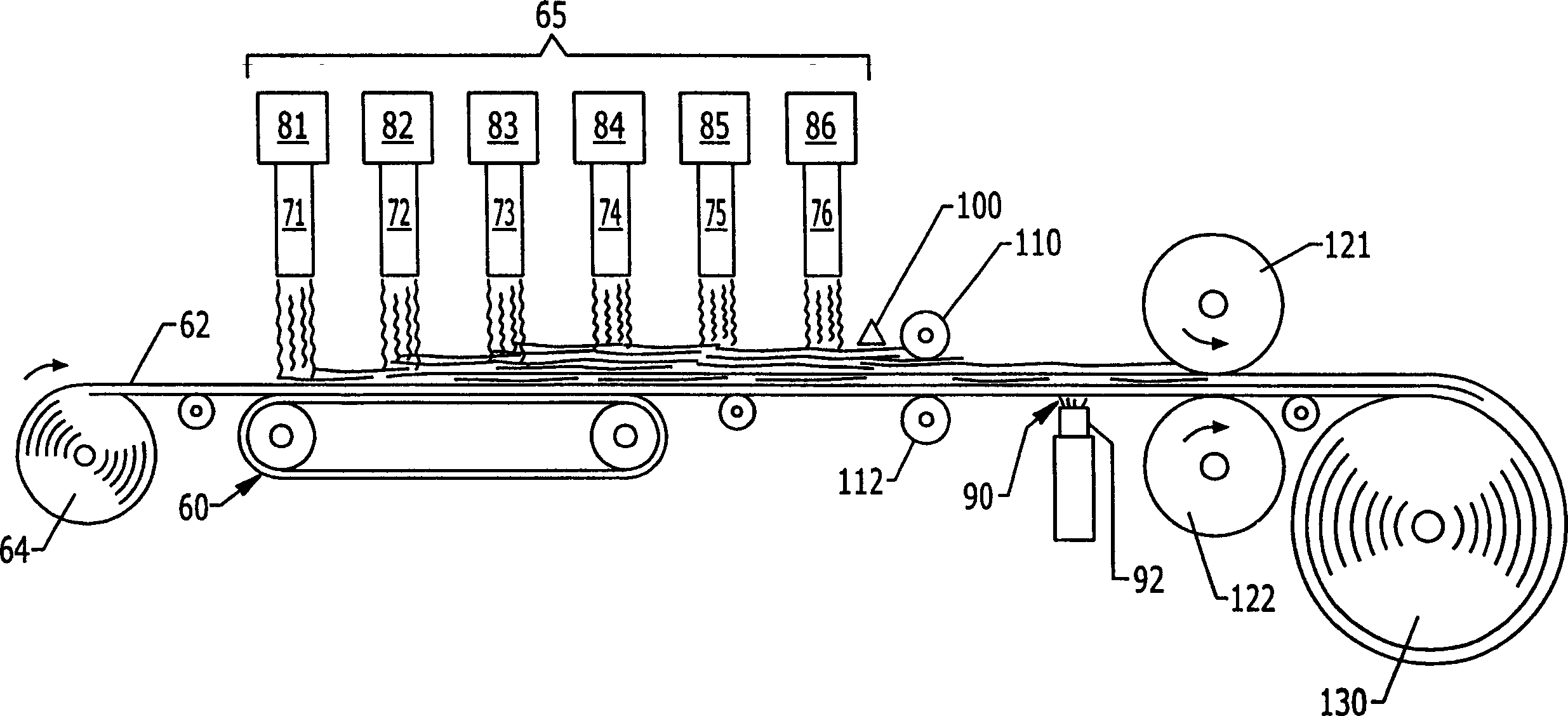

Method used

Image

Examples

Embodiment

[0084] Examples 1 to 9 of the present invention and Comparative Examples 1 to 8 used the composition of each layer provided by the following formulations A to J. The specific formulations used in each of Examples 1 to 9 and Comparative Examples 1 to 8 are shown in Table 1. The sample uses 17 gsm tissue as the carrier layer, and the tissue is commercially available and is grade 3008 tissue manufactured by Cellu Tissue Company. SAP includes the SXM 880 and SXM9200, both manufactured by Stockhansen GmbH in Krefeld, Germany. PET is a hydrophilic treated fiber with a nominal fiber length of 6 mm. The denier and geometry are shown in Table 11. The PET is manufactured by KOSA in Charlotte, NC. Cellulosic fibers are untreated pulp fibers identified as RAYFLOC-J-LD pulp fibers sold by Rayonier Inc. of Jesup, Georgia.

[0085] Formula A

[0086] Formula C

[0087] Recipe F

[0088] Formula I

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com