Anion type polymer containing tetramethylguanidine cation and its preparation method and uses

A tetramethylguanidine cation and anion technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, can solve the problems of no sulfur absorption, limited large-scale application, high synthesis cost, etc., and achieves short reaction time , high selectivity, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

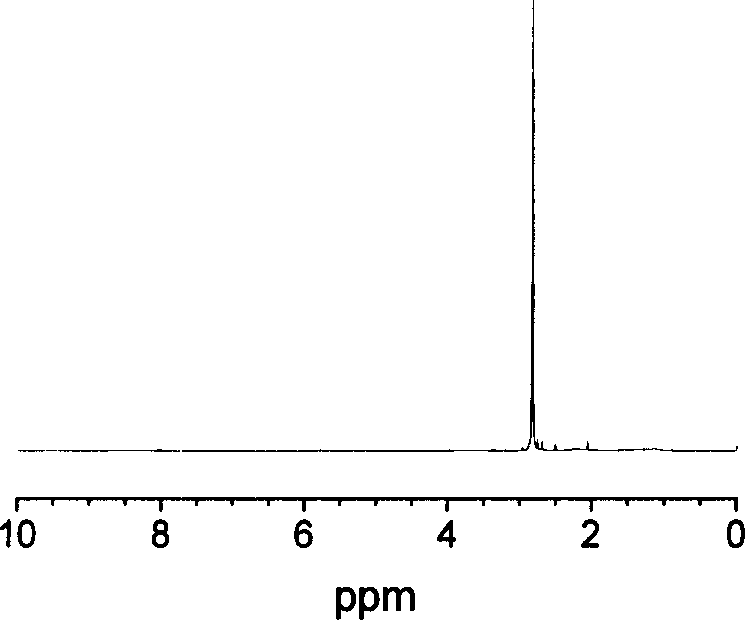

[0027] Accurately weigh 11.58 g (0.1 mol) of 1,1,3,3-tetramethylguanidine, and add it into a three-necked round-bottomed flask equipped with a condenser tube and a mechanical stirring device. Accurately weigh 7.20 g (0.1 mol) of acrylic acid and place it in a constant pressure dropping funnel. The three-necked flask was placed in an ice-water bath (0° C.), and stirring was started, and the acrylic acid solution was added dropwise. The dropwise addition was completed within 15 minutes, and the stirring was continued at room temperature for 15 minutes to obtain 1,1,3,3-tetramethylguanidine salt of ionic vinyl monomer acrylic acid. Nitrogen was passed for 0.5 hours, the temperature of the water bath was raised to 80° C., and then a free radical initiator, potassium persulfate, was added. The mass of potassium persulfate was 0.5% of the mass of the monomer. The reaction was stirred for 2 hours to obtain (polyacrylic acid 1,1,3,3-tetramethylguanidine salt), which was designated as...

Embodiment 2

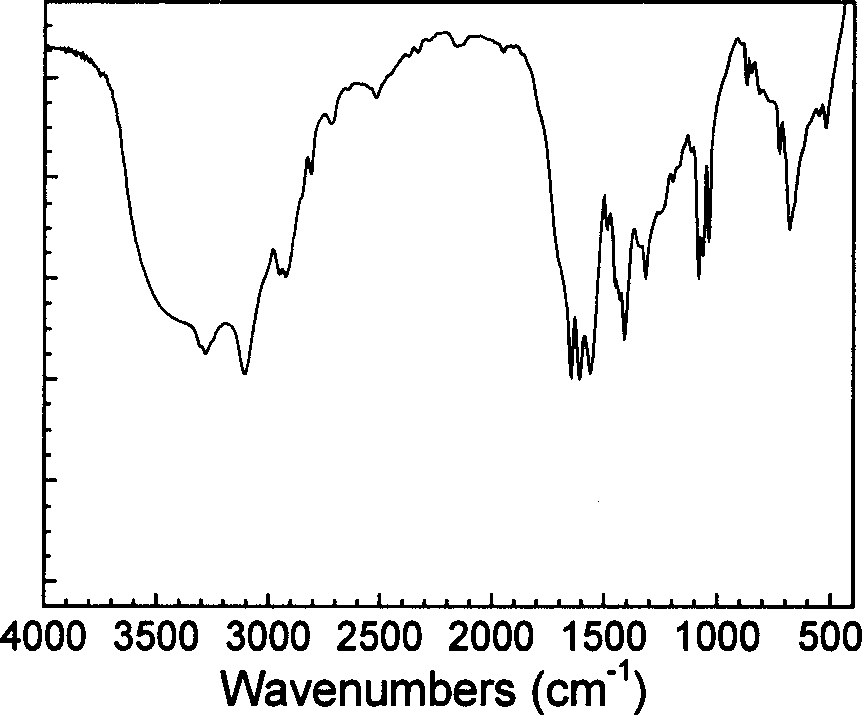

[0029] Accurately weigh 11.58 g (0.1 mol) of 1,1,3,3-tetramethylguanidine, and place it in a three-necked round-bottomed flask equipped with a condenser tube and a mechanical stirring device. Accurately weigh 8.6 grams (0.1 mol) of methacrylic acid and place it in a constant pressure dropping funnel. The three-necked flask was placed in a water bath at 30°C, and stirring was started, and methacrylic acid was added dropwise. The dropwise addition was completed within 0.5 hours, and stirring was continued at room temperature for 7.5 hours. Raise the temperature to 75° C., vacuumize for 0.5 hours, and then pass nitrogen gas for 0.5 hours, then add free radical initiator ammonium persulfate, the amount of free radical initiator is 0.05% of the monomer mass. The reaction was stirred for 8 hours to obtain (1,1,3,3-tetramethylguanidine salt of polymethacrylic acid), which was designated as polymer B. The polymer is used after pulverization. The infrared spectrum of polymethacrylic ...

Embodiment 3

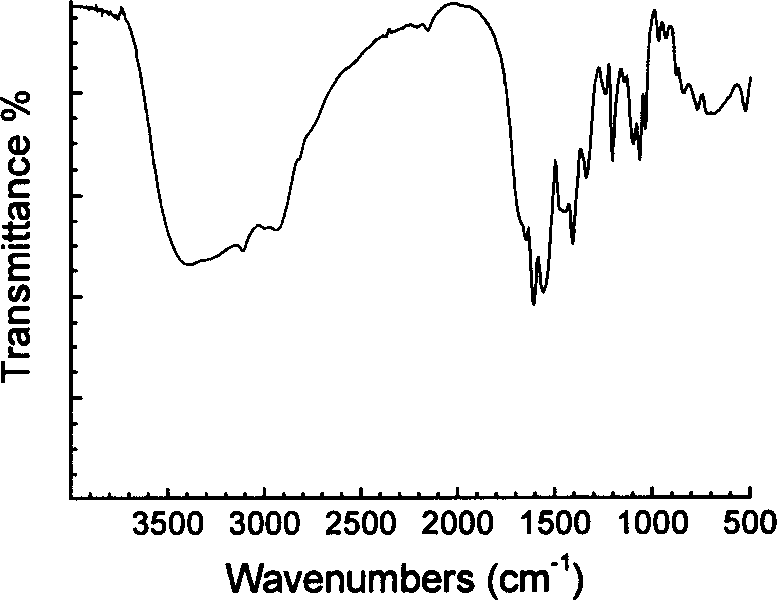

[0031] Accurately weigh 11.58 g (0.1 mol) of 1,1,3,3-tetramethylguanidine, place it in a three-necked round-bottomed flask with a condenser tube and a mechanical stirring device, and add 20 mL of deionized water. Accurately weigh 5.80 g (0.05 mol) of maleic acid, place it in a constant pressure dropping funnel, and add 20 mL of deionized water. The three-necked flask was placed in a water bath at 60°C, and stirring was started, and the maleic acid solution was added dropwise, and the dropwise addition was completed in 0.5 hours, and the stirring was continued at room temperature for 4 hours. Treat with nitrogen for 0.5 hours, raise the temperature of the water bath to 60°C, and then add the redox initiator system ammonium persulfate-sodium bisulfite, the amount of ammonium persulfate is 0.5% of the monomer mass, the mole of ammonium persulfate and sodium bisulfite The ratio is 1:3. The reaction was stirred for 8 hours, and evaporated at 120 Pa and 100° C. for 12 hours to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com