Anode material for lithium secondary battery, manufacturing method of the same, lithium secondary battery anode using the same, and lithium secondary battery

A lithium secondary battery and negative electrode material technology, which is applied in the field of negative electrode materials and preparation of the negative electrode material, can solve the problems of easily broken particles, decreased load characteristics, and reduced space, and achieve high efficiency, large discharge capacity, and excellent load characteristics. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

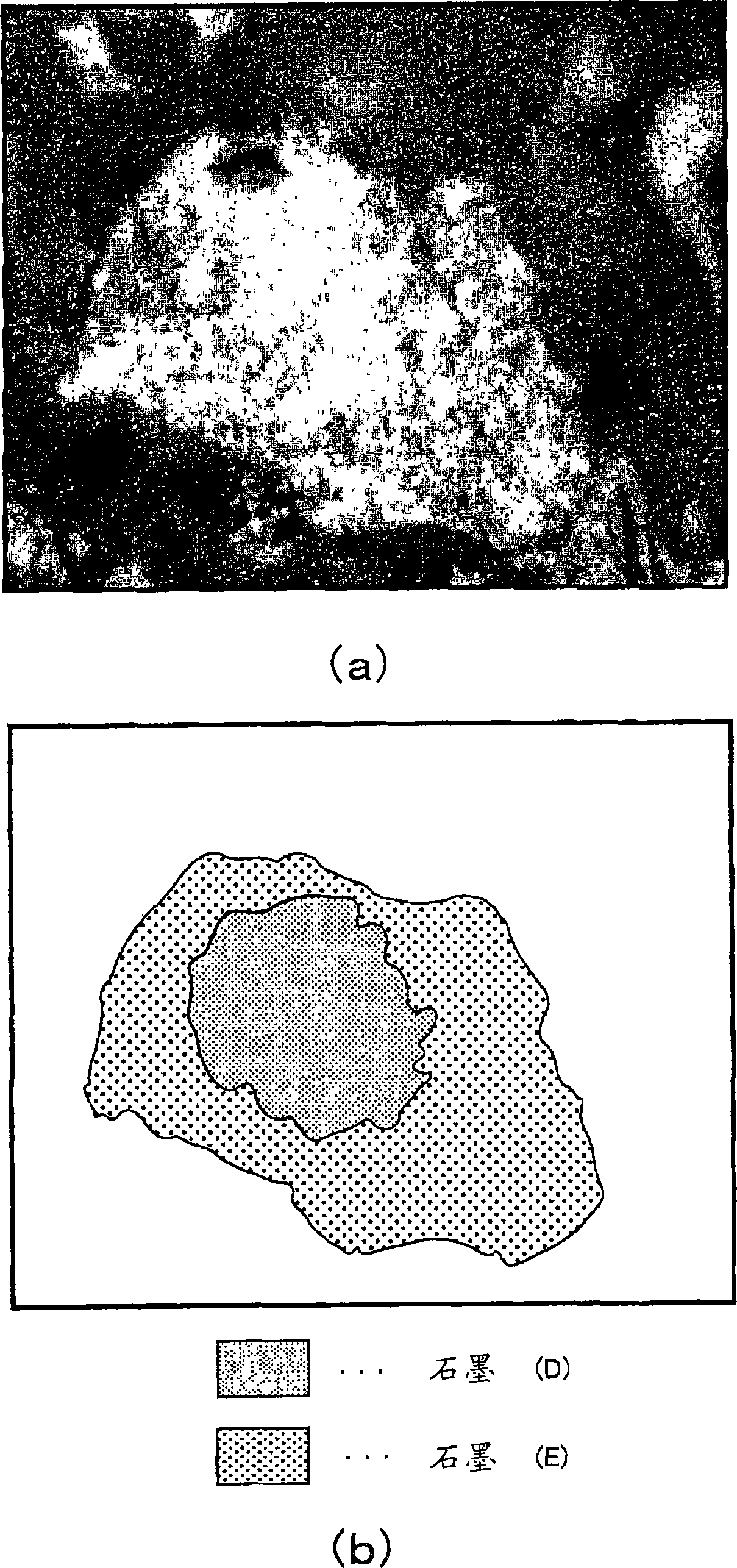

Image

Examples

preparation example Construction

[0141] (1) Preparation of electrodes

[0142] The negative electrode material is mixed with an aqueous solution of CMC (carboxymethyl cellulose) acting as a thickener and an aqueous solution of SBR (styrene butadiene rubber) acting as a binder resin, so that the negative electrode material obtained by drying, CMC The total weight of the mixture with SBR, the content of each of CMC and SBR is 1% by weight. The mixture was stirred into a slurry form, and then coated on a copper foil with a thickness of 18 μm with a doctor blade. Adjust the slit width of the doctor blade that limits the coating thickness so that the amount of electrode after drying (excluding copper foil) is 10mg / cm 2 . Then dry the obtained electrode at 80°C and press to make the electrode density (excluding copper foil) 1.63±0.05g / cm 3 .

[0143] (2) Determination of active material orientation ratio

[0144] Using the extruded electrode, the active material orientation ratio of the electrode was measured by X-ray ...

Embodiment 1

[0286] The coal tar pitch with a quinoline insoluble content of 0.05% by weight or less is heat-treated in a reaction furnace at 460°C for 10 hours to obtain a meltable block heat-treated graphite crystal precursor with a softening point of 385°C. Determine the softening point using the method described previously.

[0287] The block heat-treated graphite crystal precursor thus obtained is first pulverized with an intermediate pulverizer (Orient Mill produced by Seishin Enterprise Co., Ltd.), and then pulverized to a fine powder using a micro pulverizer (Turbo-Mill produced by Matsubo Corporation), A micronized graphite crystal precursor powder with a median diameter of 17 μm was obtained. Determine the median diameter using the method described above.

[0288] The micronized graphite crystal precursor powder obtained above is mixed with natural graphite, the median diameter of the natural graphite is 17 μm, the aspect ratio is 1.9 and the tap density is 1.0 g / cm 3 The ratio of th...

Embodiment 2

[0320] A coarse pulverizer (roller jaw crusher produced by Yoshida Manufacturing Co., Ltd.) was used to pulverize the block graphite crystal precursor mixture obtained by a similar procedure in Example 1 to coarse powder, and then a pulverizer (from Dalton Co., Hammer mill produced by Ltd.) pulverized to finer powder. The obtained fine powder was sieved with a sieve with a mesh of 45 μm to obtain a micronized graphite crystal precursor powder with a median diameter of 21.0 μm. The calcination treatment and subsequent procedures are the same as those of Example 1, to obtain a graphite composite mixed powder (C) (the negative electrode material of Example 2).

[0321] The physical properties of the negative electrode material obtained in Example 2 were measured by the same method as in Example 1. The measurement result was that the median diameter was 20.0μm and the tap density was 1.20g / cm 3 And BET specific surface area is 1.8m 2 / g. As in Example 1, the crystallinity was measured...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com