Preparation method of Ti2AlNb-based alloy large-size uniform fine-grain bar

A large-scale, base alloy technology, which is applied in the field of preparation of large-scale uniform fine-grained rods of Ti2AlNb-based alloys, can solve the problems of high deformation resistance of ingots, poor structure uniformity, and insufficient process plasticity, etc. Ability improvement, forging crack prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

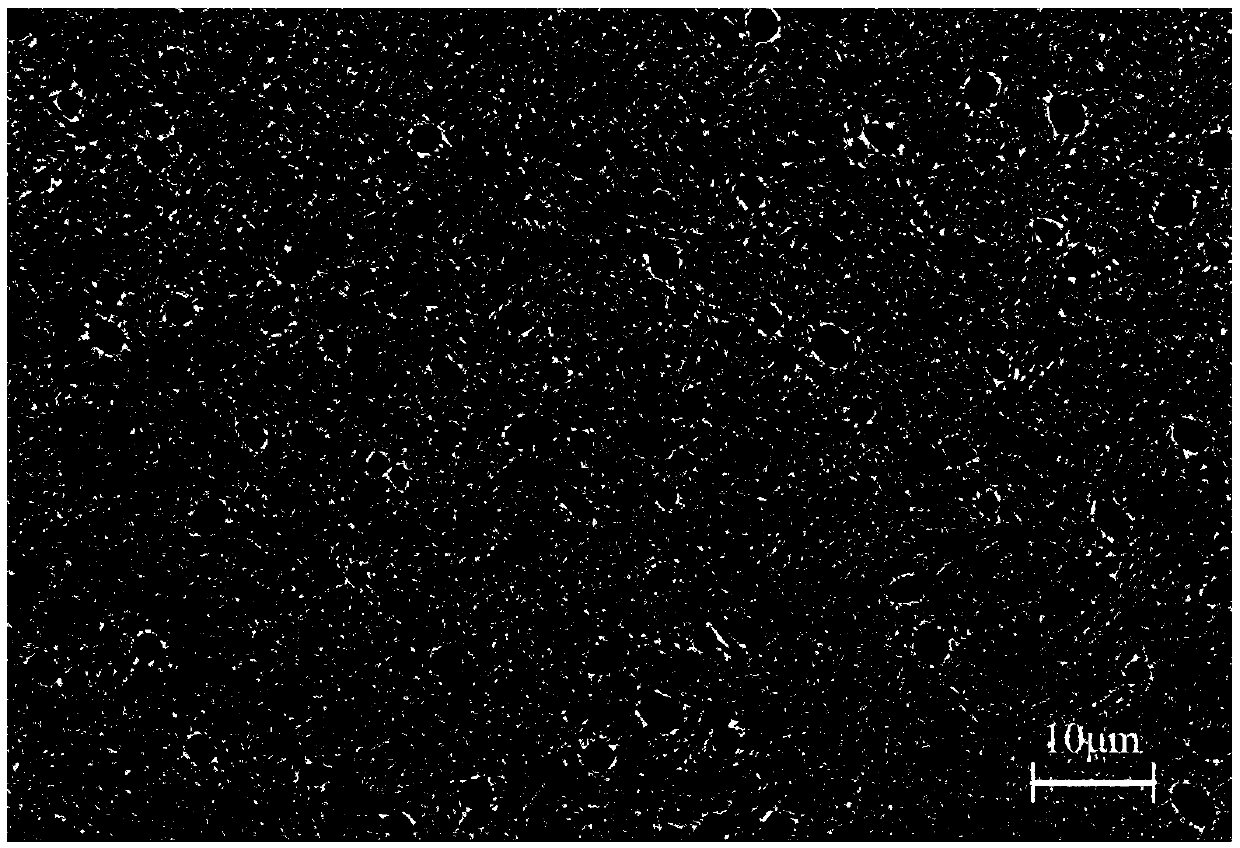

Image

Examples

preparation example Construction

[0018] The present invention will be described in further detail below. A kind of Ti 2 A method for preparing a large-scale uniform fine-grained bar of an AlNb-based alloy. The large-scale bar refers to a bar with a diameter of 150 mm to 500 mm. It is characterized in that the preparation steps are as follows:

[0019] 1. Composition homogenization treatment: Ti 2 AlNb-based alloy ingots are placed in a heating furnace for component homogenization treatment, the heating temperature is 1150 ° C ~ 1250 ° C, the holding time is 10 h ~ 30 h, furnace cooling or air cooling; the surface of the ingot before entering the furnace is coated with 0.1 mm ~ 3 mm thick High temperature resistant and anti-oxidation coating;

[0020] 2. Blank opening forging: Carry out 3 to 5 times of soft sheath blank opening upsetting and drawing forging on the billet obtained in step 1. The initial forging temperature of the billet is 1050°C to 1200°C. The amount of upsetting and drawing deformation is ...

Embodiment 1

[0031] This embodiment takes the Φ200mm bar as the target, and includes the following steps:

[0032] 1. The ingot is subjected to component homogenization heat treatment at 1180°C for 10 hours, and the ingot is coated with a 0.5mm thick type TB5-2 high temperature resistant and anti-oxidation coating before entering the furnace;

[0033]2. The billet obtained in step 1 is subjected to soft sheath blank forging for three times at the initial forging temperature range of 1050°C to 1150°C; the forging temperature for the first fire is 1150°C, and the forging temperature is lowered by 50°C for each subsequent fire; After the forging billet comes out of the furnace, quickly wrap the insulation cotton with a thickness of 20mm and then forge; complete one upsetting and one pulling out for each fire, and the deformation of upsetting and pulling is 40%; the final forging temperature is not lower than 800 ° C, and it is naturally cooled after each fire forging;

[0034] 3. Carry out so...

Embodiment 2

[0041] This embodiment takes the Φ300mm bar as the target, and includes the following steps:

[0042] 1. The ingot is subjected to a composition homogenization heat treatment at 1200°C for 15 hours, and the ingot is coated with a 1mm thick type of TB1260-16 high temperature resistant and anti-oxidation coating before entering the furnace;

[0043] 2. The billet obtained in step 1 is subjected to soft sheath blank forging for three times at the initial forging temperature range of 1120°C to 1180°C; the forging temperature for the first fire is 1180°C, and the forging temperature is lowered by 30°C for each subsequent fire; After the forging billet comes out of the furnace, it is quickly wrapped with insulation cotton with a thickness of 25mm and then forged; one upsetting and one drawing are completed for each fire, and the deformation of upsetting and drawing is 35%; the final forging temperature is not lower than 800°C, and it is naturally cooled after each fire forging;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com