Preparation method of MoS2/MoO2 heterojunction

A heterojunction and quartz tube technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of easy introduction of impurities, poor repeatability, etc., and achieve the effect of simple reaction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In SiO 2 / Si substrate prepared MoS 2 / MoO 2 Heterojunction.

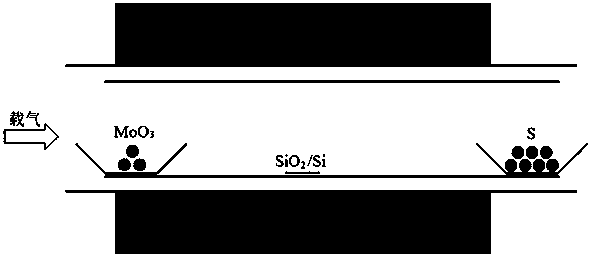

[0033] (1) In the quartz tube furnace, the ceramic boat containing S powder was placed downstream of the gas path, at a position 17 cm away from the center of the tube furnace, filled with MoO 3 The ceramic boat of the powder is placed upstream of the gas path, 10cm away from the center of the tube furnace, and the SiO 2 / Si substrate is placed in the center of the tube furnace temperature zone, where S powder and MoO 3 The masses of the powders are 200mg and 6mg respectively;

[0034] (2) Use a mechanical pump to pump out the air in the quartz tube, and then fill it with argon until the pressure in the quartz tube returns to atmospheric pressure, then use a mechanical pump to pump out the gas in the quartz tube again, and fill it with argon again to make the quartz tube The pressure in the tube returns to atmospheric pressure;

[0035] (3) Adjust the flow rate of argon to 20 sccm, and heat the tube fu...

Embodiment 2

[0038] The experimental procedure is exactly the same as that of Example 1, except that the argon gas flow rate of 30 sccm remains unchanged throughout the growth process.

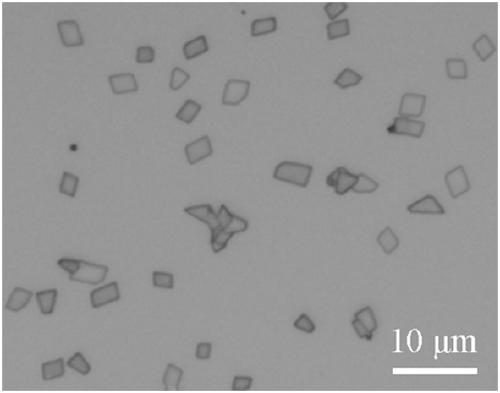

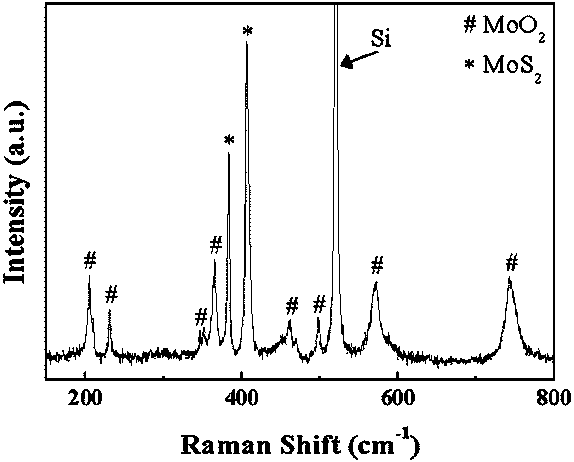

[0039] When the carrier gas flow rate increased to 30 sccm, the concentration of S vapor in the temperature zone increased, and rhombohedral grains were formed on the surface of the substrate after the growth, and the Raman test results at different positions showed that these grains were partly MoO 2 , partly MoS2 / MoO 2 heterojunction, such as Figure 5-7 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com