Enzymatic catalysis prepared special grease for quick-frozen food and preparation method thereof

A technology for catalytic preparation and quick-frozen food, applied in the field of special oils and fats, can solve the problems of producing trans fatty acids, cumbersome production process, and difficult to separate by-products, etc., and achieve the effects of easy separation, less environmental pollution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh raw materials according to the following formula (weight): Lipozyme RM IM 8g, palm stearin 70g, soybean oil 30g, glyceryl monostearate 0.8g, lecithin 0.2g, Span 80 0.5g, butylated hydroxyfennel Ether 0.005g, 2,6-di-tert-butyl-p-cresol 0.003g.

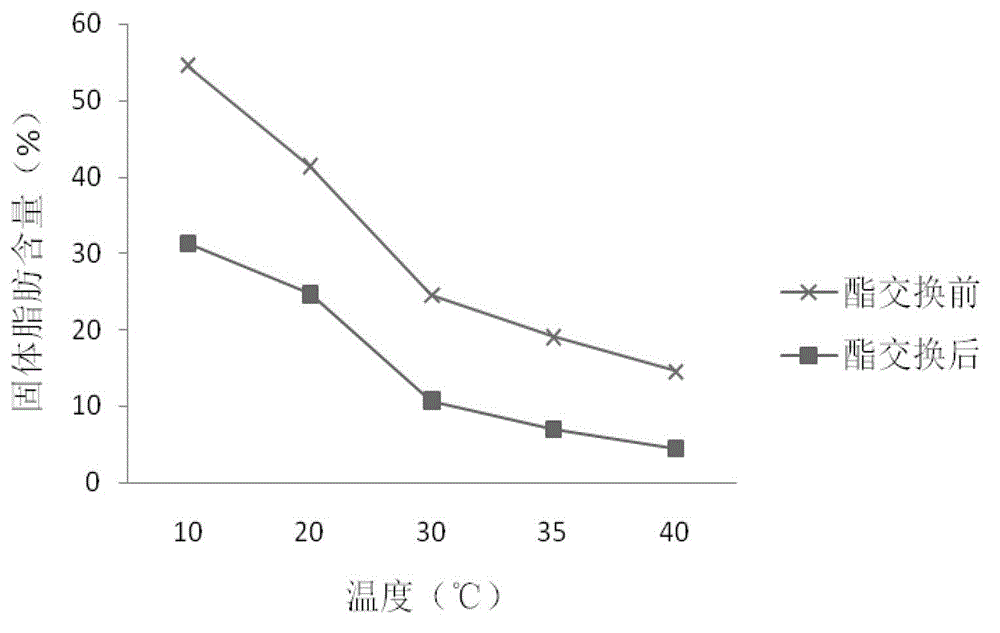

[0027] The preparation method of quick-freezing special oil: add 70g palm stearin and 30g soybean oil into a closed container, then add 8g lipase, and then stir at a stirring rate of 150 rpm, a reaction temperature of 60°C, and a reaction time of 2 hours. After the reaction is finished, the lipase is filtered out to obtain lactidified oil. At 60°C, add 0.005g of butylhydroxyanisole and 0.003g of 2,6-di-tert-butyl-p-cresol to the lactidified oil, stir and mix well; then add 0.8g of monostearic acid Glycerides, 0.2g lecithin and 0.5g Span 80 are emulsified under heating, the emulsification rate is 500 rpm, the emulsification temperature is 70°C, and the emulsification time is 10 minutes; then the uniformly emulsified oil is ...

Embodiment 2

[0030] Weigh raw materials according to the following formula (weight): Lipozyme RM IM 7g, palm stearin 70g, palm olein 30g, glyceryl monostearate 0.9g, lecithin 0.2g, Span 800.7g, butylated hydroxyfennel Ether 0.004g, 2,6-di-tert-butyl-p-cresol 0.003g.

[0031] Preparation method of quick-freezing special fat: add 70g palm stearin and 30g palm olein into a closed container, then add 7g lipase, and then stir at a stirring rate of 160 rpm, a reaction temperature of 55°C, and a reaction time of 3 hours. After the reaction is finished, the lipase is filtered out to obtain lactidified oil. At 55°C, add 0.004g of butylhydroxyanisole and 0.003g of 2,6-di-tert-butyl-p-cresol to the lactidified oil, stir and mix well; then add 0.9g of monostearic acid Glycerides, 0.2g lecithin and 0.7g Span 80 are emulsified under heating, the emulsification rate is 700 rpm, the emulsification temperature is 70°C, and the emulsification time is 10 minutes; then the uniformly emulsified oil is quickly...

Embodiment 3

[0033] Weigh raw materials according to the following formula (weight): Lipozyme RM IM 6g, palm stearin 70g, sunflower oil 30g, glyceryl monostearate 0.8g, lecithin 0.3g, Span 800.7g, butylated hydroxyfennel Ether 0.005g, 2,6-di-tert-butyl-p-cresol 0.004g.

[0034] The preparation method of quick-frozen special oil: add 70g palm stearin and 30g sunflower oil into a closed container, then add 6g lipase, and then stir at a stirring rate of 170 rpm, a reaction temperature of 65°C, and a reaction time of 2.5 hours. After the reaction is finished, the lipase is filtered out to obtain lactidified oil. At 65°C, add 0.005g butyl hydroxyanisole and 0.004g 2,6-di-tert-butyl p-cresol to the lactide fat, stir and mix well; then add 0.8g monostearic acid Glycerides, 0.3g lecithin and 0.7g Span 80 are emulsified under heating, the emulsification rate is 800 rpm, the emulsification temperature is 70°C, and the emulsification time is 10 minutes; then the uniformly emulsified oil is quickly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com