Hydraulic pipe orifice assembly reshaping device

A hydraulic nozzle technology, applied in the field of hydraulic nozzle group shaping equipment, can solve the problems of low construction efficiency, difficult bottom shaping, high cost, etc., and achieve the effects of convenient loading and unloading, reduced labor intensity and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

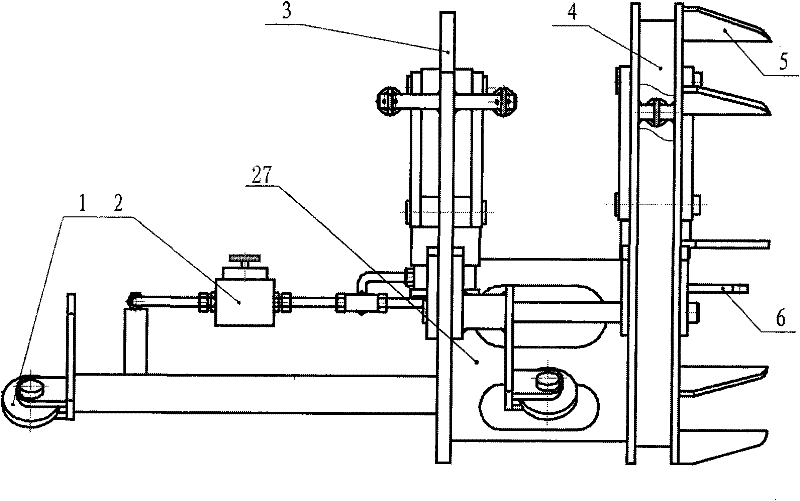

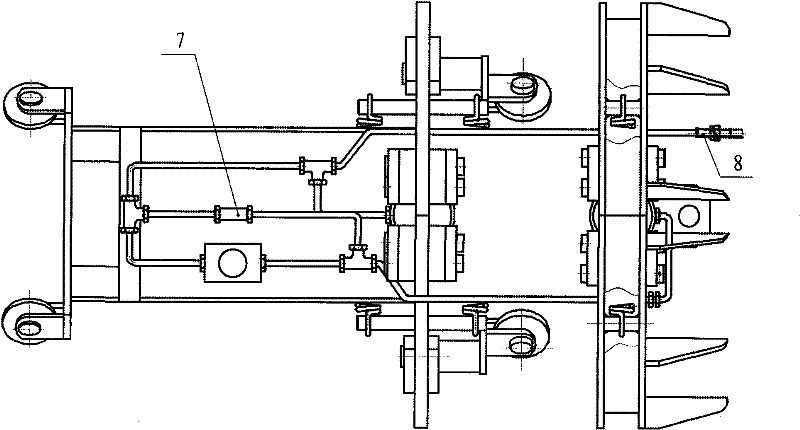

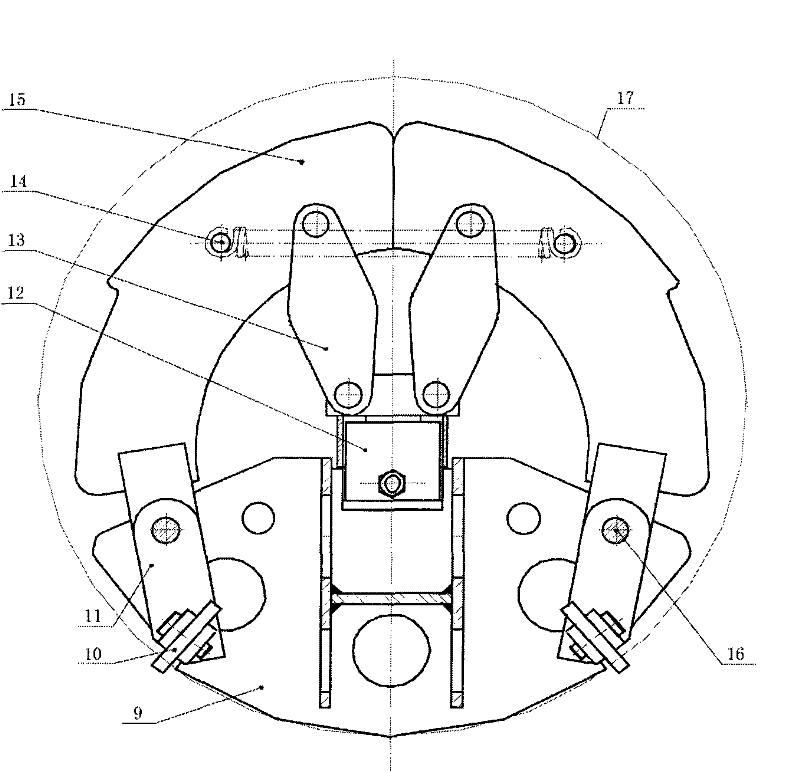

[0012] In the figure: 1-rear roller 2-sequence valve 3-positioning plate 4-shaping plate 5-guide plate 6-traction plate 7-one-way valve 8-oil pipe quick connector 9-positioning plate lower plate 10-front roller 11-roller bracket 12-Positioning plate plunger cylinder 13-Positioning plate push rod 14-Positioning plate return spring 15-Positioning plate upper plate 16-Positioning plate pin shaft 17 Pipeline 18-Shaping plate lower plate 19-Shaping plate plunger cylinder 20-Shaping plate Upper plate 21 Shaping disc return spring 22- Shaping disc push rod 23- Ultra-high pressure hydraulic power station (ultra-high pressure pump source) 24- Reversing valve 25- Hydraulic control check valve 28- Shaping disc pin 27- Rack.

[0013] Such as figure 1 As shown, the best embodiment of the hydraulic nozzle group pair shaping equipment of the present invention includes four parts: a positioning plate 3, a shaping plate 4, a traveling roller and an ultra-high pressure hydraulic system.

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com