Molybdenum disulfide nano-sheet preparation method based on sodium chloride template

A molybdenum disulfide and nanosheet technology, applied in the field of molybdenum disulfide nanosheet materials and preparation thereof, can solve the problems of difficulty in obtaining dispersed molybdenum disulfide nanosheets, uneven size and thickness distribution, and easy damage to the nanosheets. , to achieve the effect of excellent morphology, low cost and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

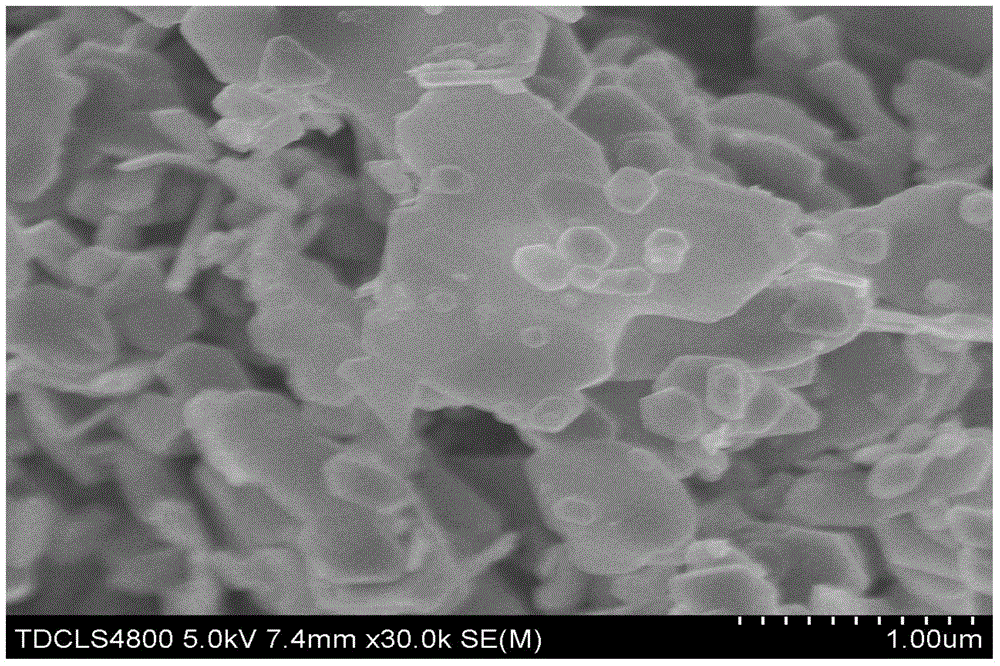

[0022] Take by weighing 0.3531g ammonium molybdate, 0.3654g thiourea and 35.1g sodium chloride, dissolve the mixture in 200ml of deionized water, stir and dissolve to form a solution with a magnetic stirrer with a stirring speed of 300r / min, and then Sonicate with a 400W sonicator for 15 minutes and mix well. Put the mixture in the refrigerator for 12 hours to freeze, and then place it in a freeze dryer at -50°C for vacuum drying until the mixture is dried. Grind the mixture and pass through a 150-mesh sieve, take 10g of powder and place it in the ark, put the ark in a tube furnace, pass through the Ar inert gas of 200ml / min to remove the air, then use the Ar inert gas of 200ml / min, and use 10 The heating rate of ℃ / min is raised to 750 ℃, and the temperature is kept for 2 hours for chemical vapor deposition. After the reaction is completed, it is cooled to room temperature under the protection of Ar atmosphere to obtain the calcined product A, which is collected, ground and wa...

Embodiment 2

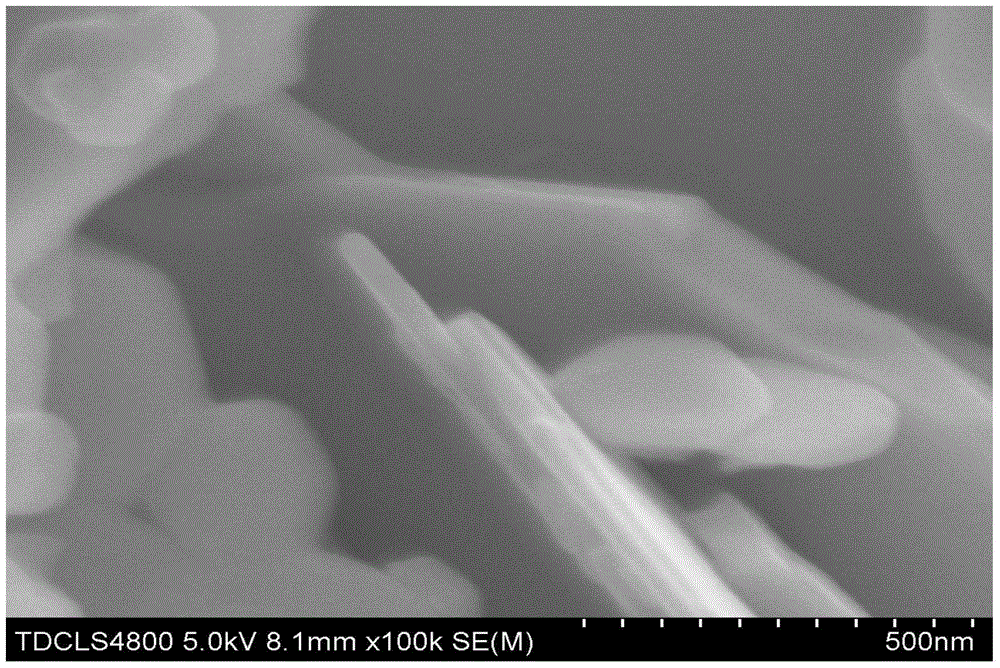

[0025] Weigh 0.1765g ammonium molybdate, 0.1827g thiourea and 17.55g sodium chloride, dissolve the mixture in 150ml of deionized water, stir and dissolve to form a solution with a magnetic stirrer with a stirring speed of 300r / min, and then Sonicate with a 400W sonicator for 15 minutes and mix well. Put the mixture in the refrigerator for 12 hours to freeze, and then place it in a freeze dryer at -50°C for vacuum drying until the mixture is dried. Grind the mixture and pass through a 100-mesh sieve, take 10g of powder and place it in the ark, put the ark into the tube furnace, pass through the Ar inert gas of 200ml / min to remove the air, then use the Ar inert gas of 200ml / min, and use 10 The heating rate of ℃ / min is raised to 600 ℃, and the temperature is kept for 3 hours for chemical vapor deposition. After the reaction is completed, it is cooled to room temperature under the protection of Ar atmosphere to obtain the calcined product A, which is collected, ground and washed w...

Embodiment 3

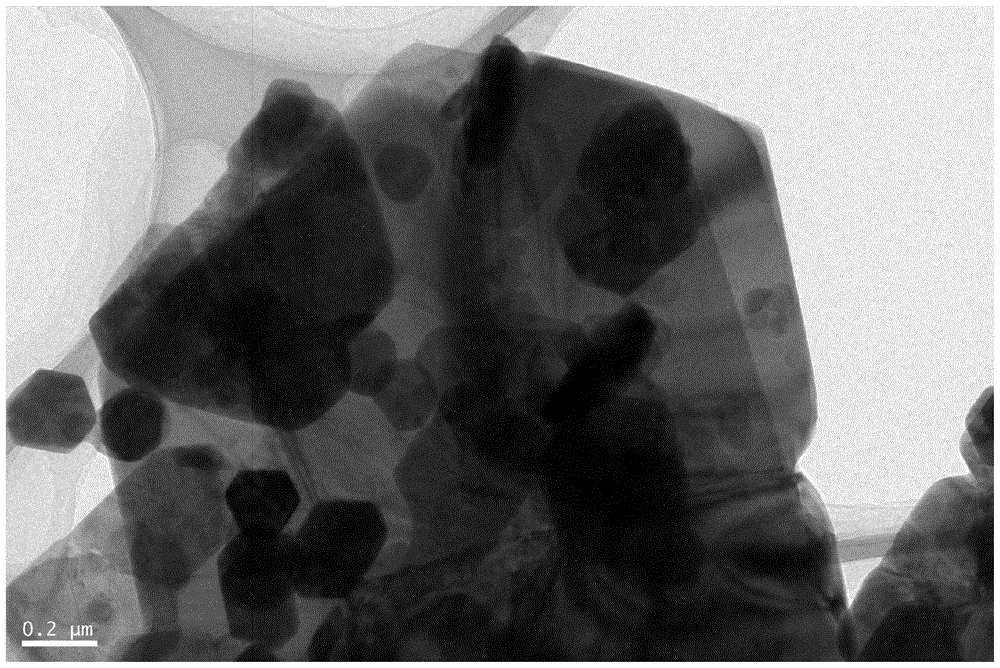

[0027] Take by weighing 0.1765g sodium molybdate, 0.1827g thiourea and 26.325g sodium chloride, dissolve the mixture in 200ml of deionized water, stir and dissolve to form a solution with a magnetic stirrer with a stirring speed of 300r / min, and then Sonicate with a 400W sonicator for 15 minutes and mix well. Put the mixture in the refrigerator for 12 hours to freeze, and then place it in a freeze dryer for vacuum drying at -40°C until the mixture is dried. Grind the mixture and pass through a 150-mesh sieve, take 10g of powder and place it in the ark, put the ark in a tube furnace, pass through the Ar inert gas of 200ml / min to remove the air, then use the Ar inert gas of 200ml / min, and use 10 The heating rate of ℃ / min is raised to 750 ℃, and the temperature is kept for 2 hours for chemical vapor deposition. After the reaction is completed, it is cooled to room temperature under the protection of Ar atmosphere to obtain the calcined product A, which is collected, ground and wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com