Tennis ball felt and tennis ball

a tennis ball and felt technology, applied in the field of felt, can solve problems such as prone to creases, and achieve the effects of preventing effective irregular ball bounding, reducing creases, and excellent aesthetic appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

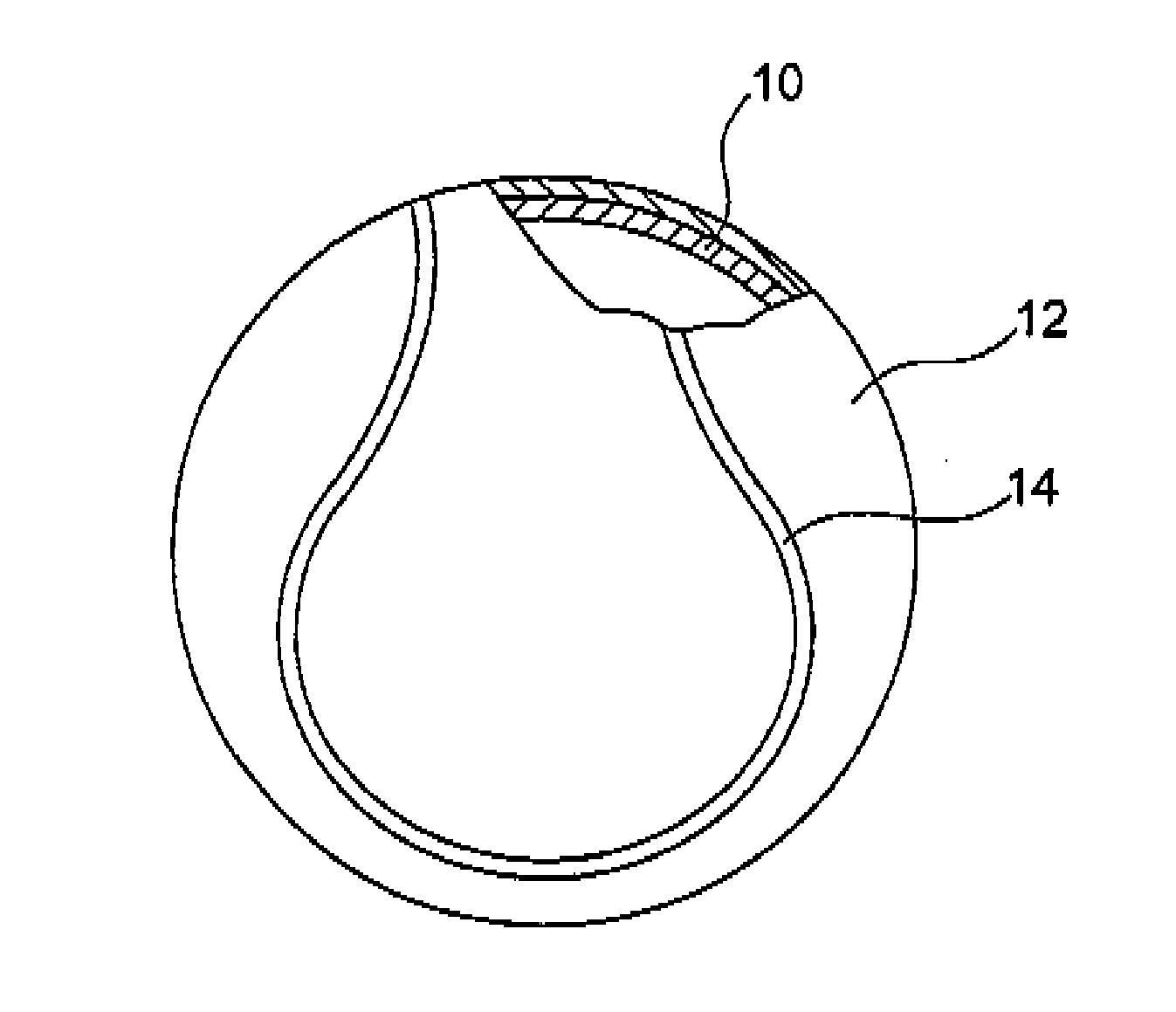

Image

Examples

Embodiment Construction

[0023]The invention will be described below more detailedly. A tennis ball felt of the invention is formed by fixing a base fabric and fibers together. In the invention, in case that the base fabric is formed of stretchy material, examples of the stretchy material can include stretchy polyurethane, polyethylene terephthalate, nylon, a mixture of polyurethane and polyethylene terephthalate, a mixture of polyurethane and nylon, a mixture of nylon and polyethylene terephthalate, a mixture of polyurethane, nylon and cotton, and synthetic rubber. The most preferable material of these materials is, from points of excellent stretch property, and suitable thickness and weight, polyurethane.

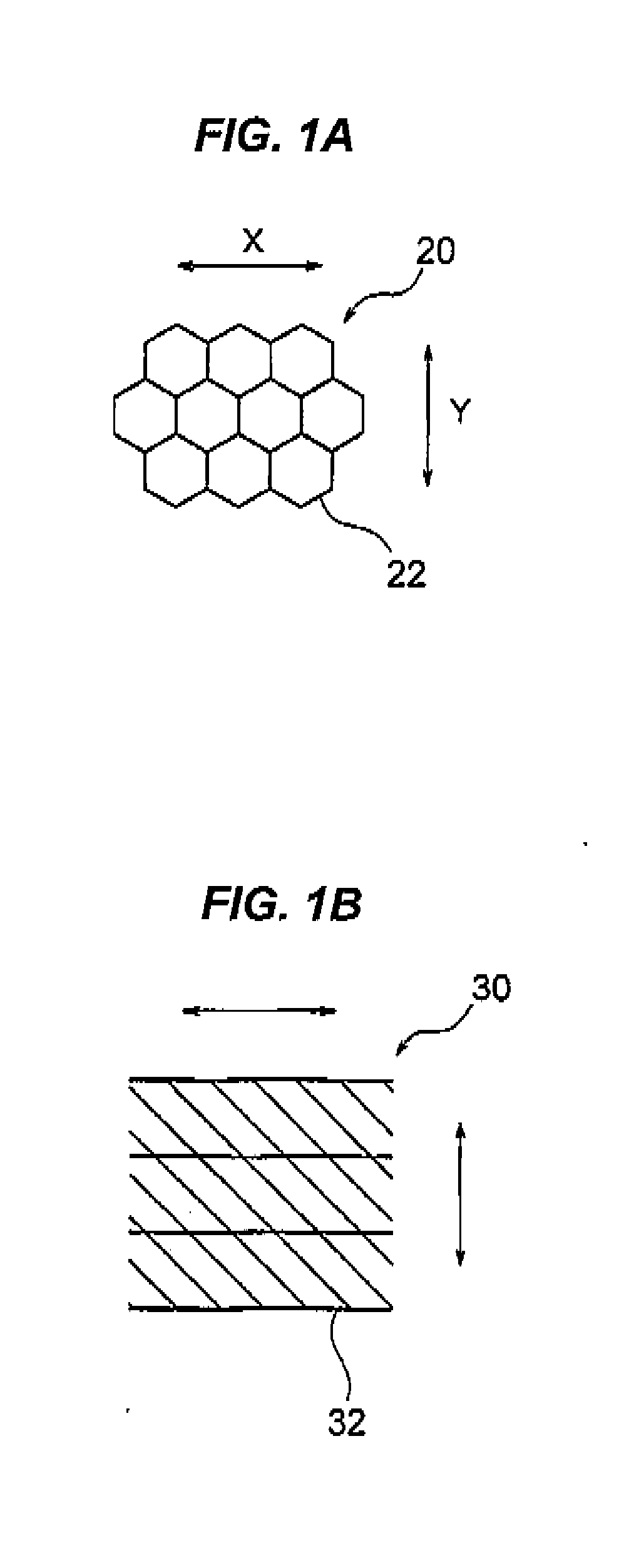

[0024]Further, in case that the base fabric having the mesh structure which develops the stretch property is used, examples of the above mesh structure can include the structure shown in FIGS. 1A and 1B. In a mesh structure 20 shown in FIG. 1A, each mesh 22 is hexagonal; and in a mesh structure 30 shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com