Metal pipe inner surface electrodeposition device and method

A technology of electrodeposition device and metal tube, which is applied in current conduction device, sealing device, electrolysis process, etc., can solve the problems of environmental pollution, affecting the efficiency of operation, and occupying a large area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

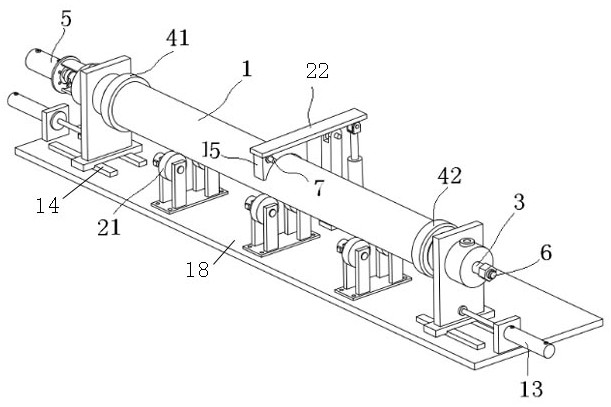

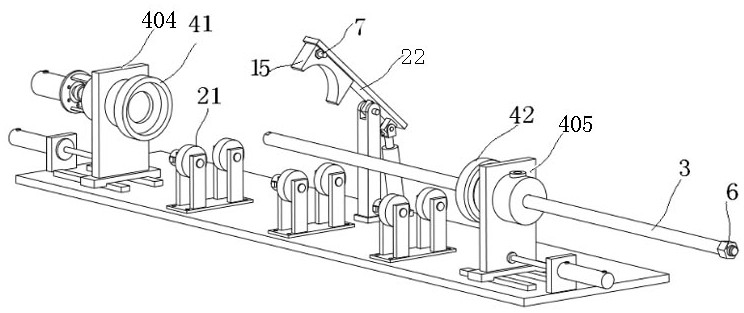

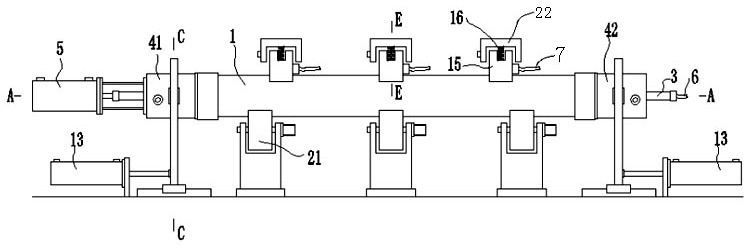

[0036] refer to Figure 1 to Figure 5 As shown, the electrodeposition device for the inner surface of a metal tube provided by the present invention includes a base 18 , an anode 3 , a carbon brush 15 , a compound joint, a reciprocating drive part 5 and a plurality of liquid storage tanks 8 .

[0037] The base 18 is provided with a plurality of support rollers 21 for horizontally supporting the metal pipe 1 and driving its circumferential rotation, and the base 18 is also provided with a motor for driving the support rollers 21 to rotate. The metal pipe 1 is horizontally supported and driven to rotate in the circumferential direction by the support roller 21 . Both ends of the base 18 are also respectively provided with a first slide 404 and a second slide 405, and the metal pipe 1 is located between the first slide 404 and the second slide 405; the middle part of the base 18 is also provided with a swing frame 22, An elastic member 16 for pressing the arc groove of the carbo...

Embodiment 2

[0045] As a preferred embodiment, it is basically the same as Embodiment 1, except that the front composite joint 41 and the rear composite joint 42 respectively include a front pipe section 401, a rear pipe section 402 and a rotary seal, and the rotary seal is arranged on the front pipe section 401 and the rear pipe section 401. Between the rear pipe sections 402, the liquid delivery port 403 is arranged in the rear pipe section 402 and communicates with the inner cavity of the rear pipe section 402. The front end of the front pipe section 401 is provided with an interface connected with the end of the metal pipe 1, and the rear pipe section 402 can slide up and down. It is arranged on the first sliding seat 404 , and similarly, the rear pipe section 402 of the rear composite joint 42 is arranged on the second sliding seat 405 so that it can slide up and down. The front end of the metal pipe 1 is fixedly connected and sealed to the interface of the front pipe section 401, and ...

Embodiment 3

[0056] Basically the same as Embodiment 2, the difference is that, as Figure 7 As shown, each liquid storage tank 8 includes a front liquid storage tank 81 and a rear liquid storage tank 82. The liquid delivery port is connected, and a filter part 9 for removing impurities is arranged between the front liquid storage tank and the rear liquid storage tank of the same liquid storage tank, and the filter part 9 for filtering out liquid impurities.

[0057] In addition, a filter member 9 for filtering out liquid impurities is provided between the delivery pipes at both ends in each liquid storage tank.

[0058] Wherein, the filter part 9 is an element for removing solid impurities in the liquid, such as a filter, a filter membrane, a filter screen, etc., which are conventional general-purpose products in industrial technology, and will not occupy space to repeat its detailed structure, working principle and other content.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com