Device for measuring and adjusting bogie size of motor train unit

A technology for adjusting equipment and bogies, used in railway vehicle testing, lifting frames, lifting devices, etc., can solve problems such as prolonging operation time and increasing operation difficulty, and achieves the effect of saving operation sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

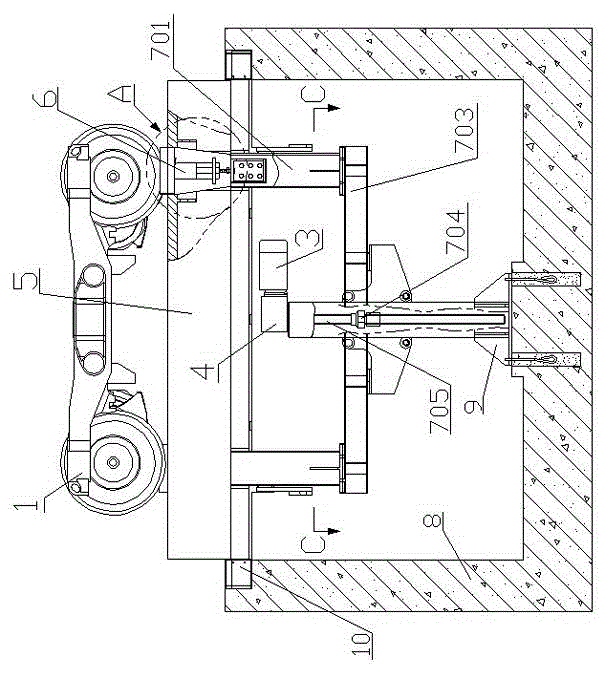

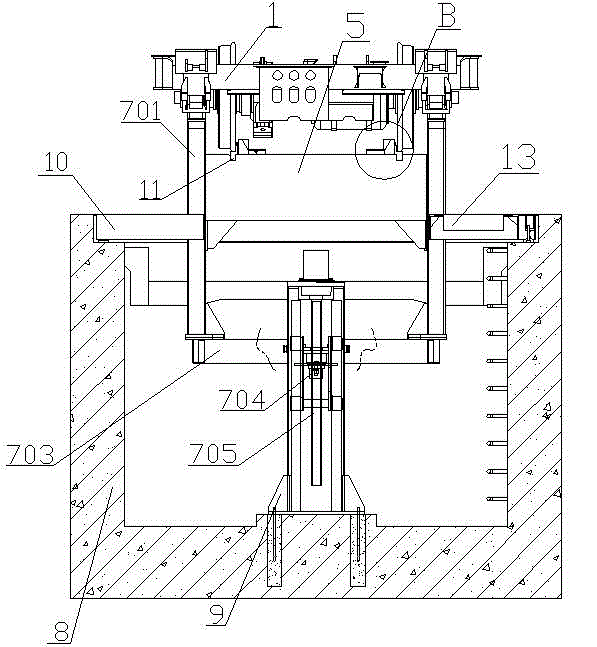

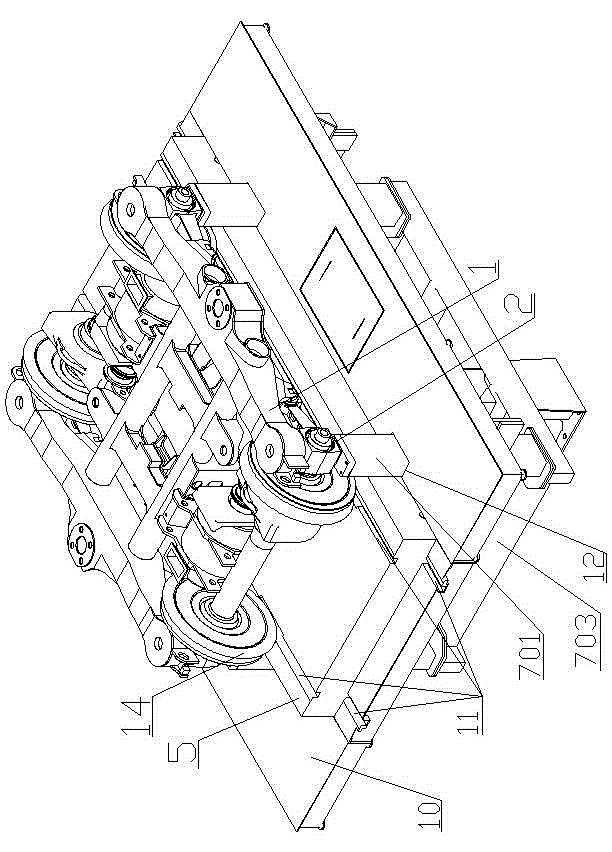

[0023] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0024] An EMU bogie size measurement and adjustment equipment, see attached figure 1 to attach Figure 7 , in the figure: bogie 1, positioning arm 2, driving motor 3, reducer 4, measuring platform 5, wheel positioning mechanism 6, adjusting bolt 601, positioning block 602, guide plate 603, positioning pin 604, bracket 605, support Plate 607, lifting column 701, lifting bracket 703, lead screw nut 704, lead screw 705, foundation 8, support 9, fixed platform 10, track 11, positioning hole 12, cover plate 13, wheel 14, hand Pull valve 1501, cylinder 1502, locking block 1503.

[0025] In this embodiment, the fixed platform 10 is a rectangular hollow structure, and the measuring platform 4 is frame-shaped. There is a gap of about 1 mm between the two), the fixed platform 10 and the measuring platform 4 are respectively provided with two rails 11 in a paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com