Cold-mould vertical spraying and cleaning system

A cold and vertical technology, used in casting and forming equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of large floor space, low relative efficiency, difficult manual control, etc., to save work space and large bearing capacity. , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

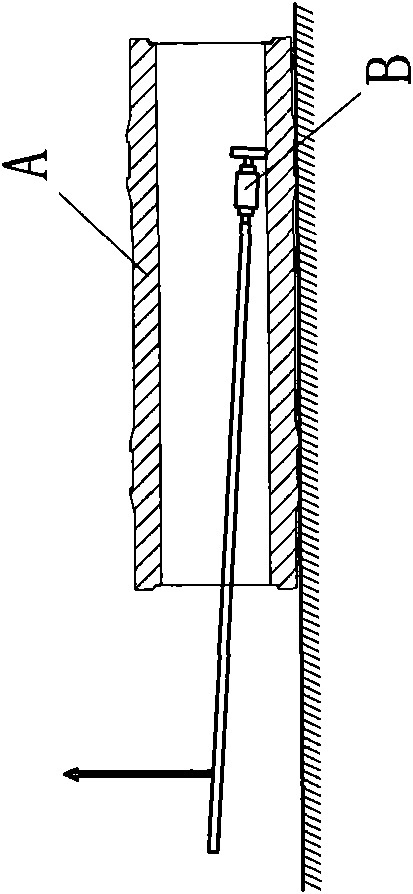

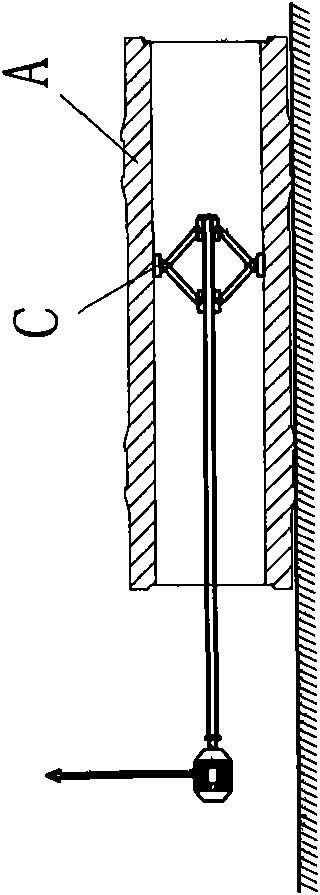

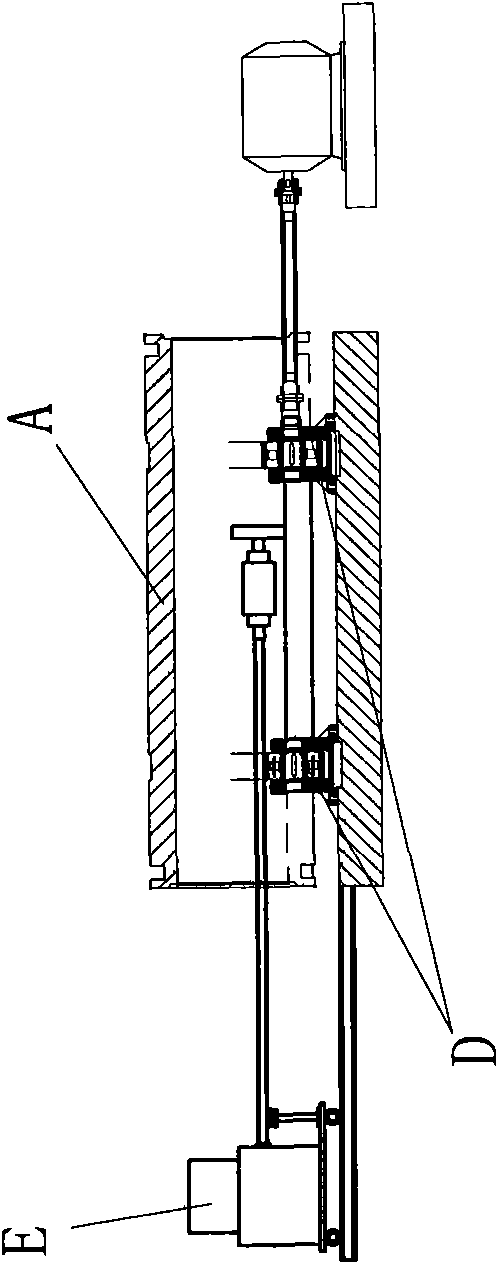

[0032] Such as figure 2 , image 3As shown, a cold type vertical spraying and cleaning system, the spraying and cleaning system includes a pit 8 capable of accommodating the cold type 9 vertically, and the bottom of the pit 8 is provided with a fixed support cold type 9 The bottom end drives the hollow rotating bracket 7 that rotates around the longitudinal axis of the cold type 9; the dust removal device 6 is arranged under the hollow rotating bracket 7; the operating vehicle 5 that can move along the pit is arranged on the top of the pit 8 , the operating vehicle 5 is provided with a vertically arranged hollow guide rod 4 that can move up and down, and the lower port of the hollow guide rod 4 is provided with an actuator; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com