Bottle

a bottle and bottle body technology, applied in the field of bottles, can solve the problems of inherently susceptible deformation of plastic bottles, and achieve the effects of positive deflection, reducing the risk of deformation, and maintaining the stiffness of the bottle hoop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

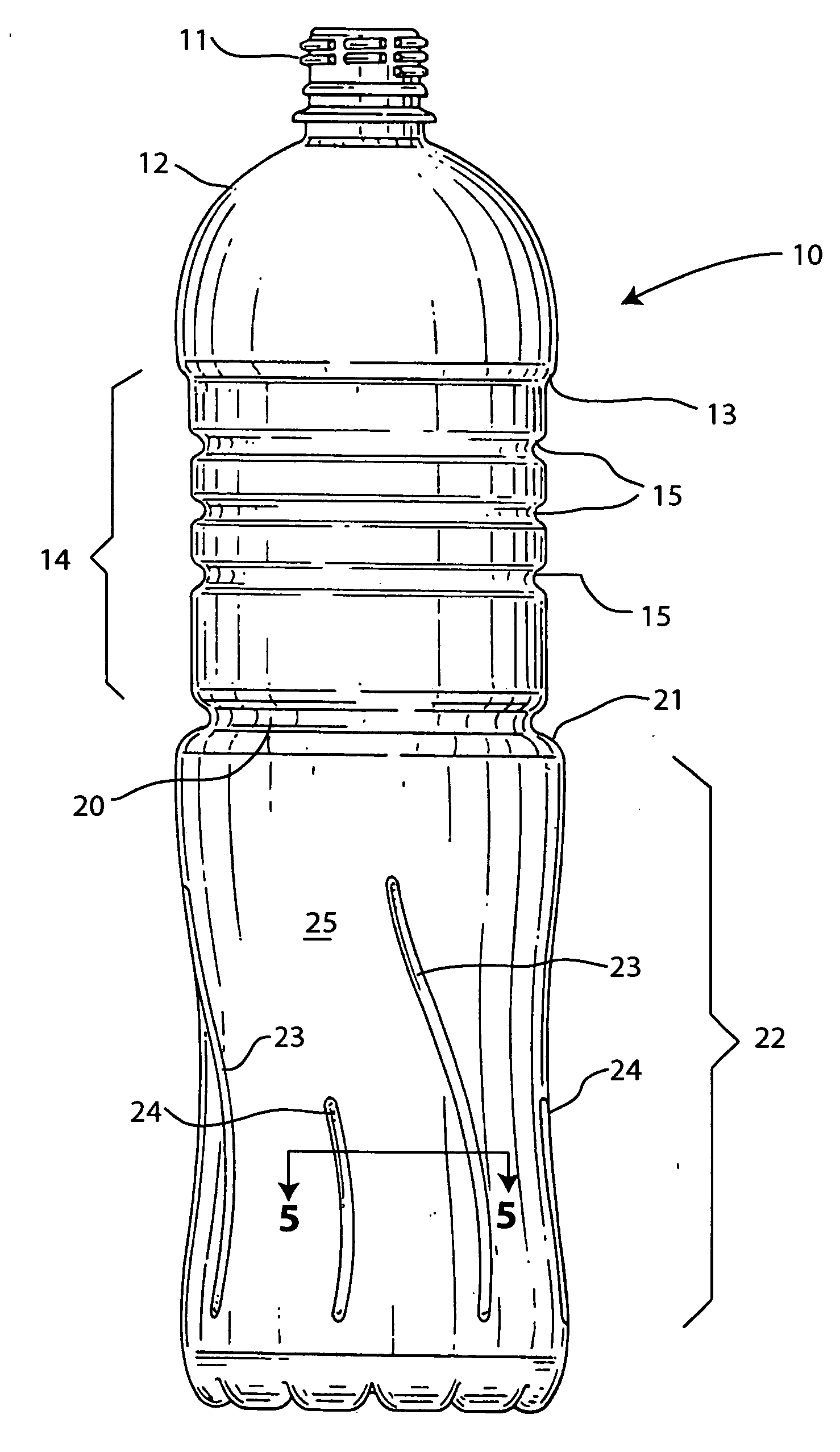

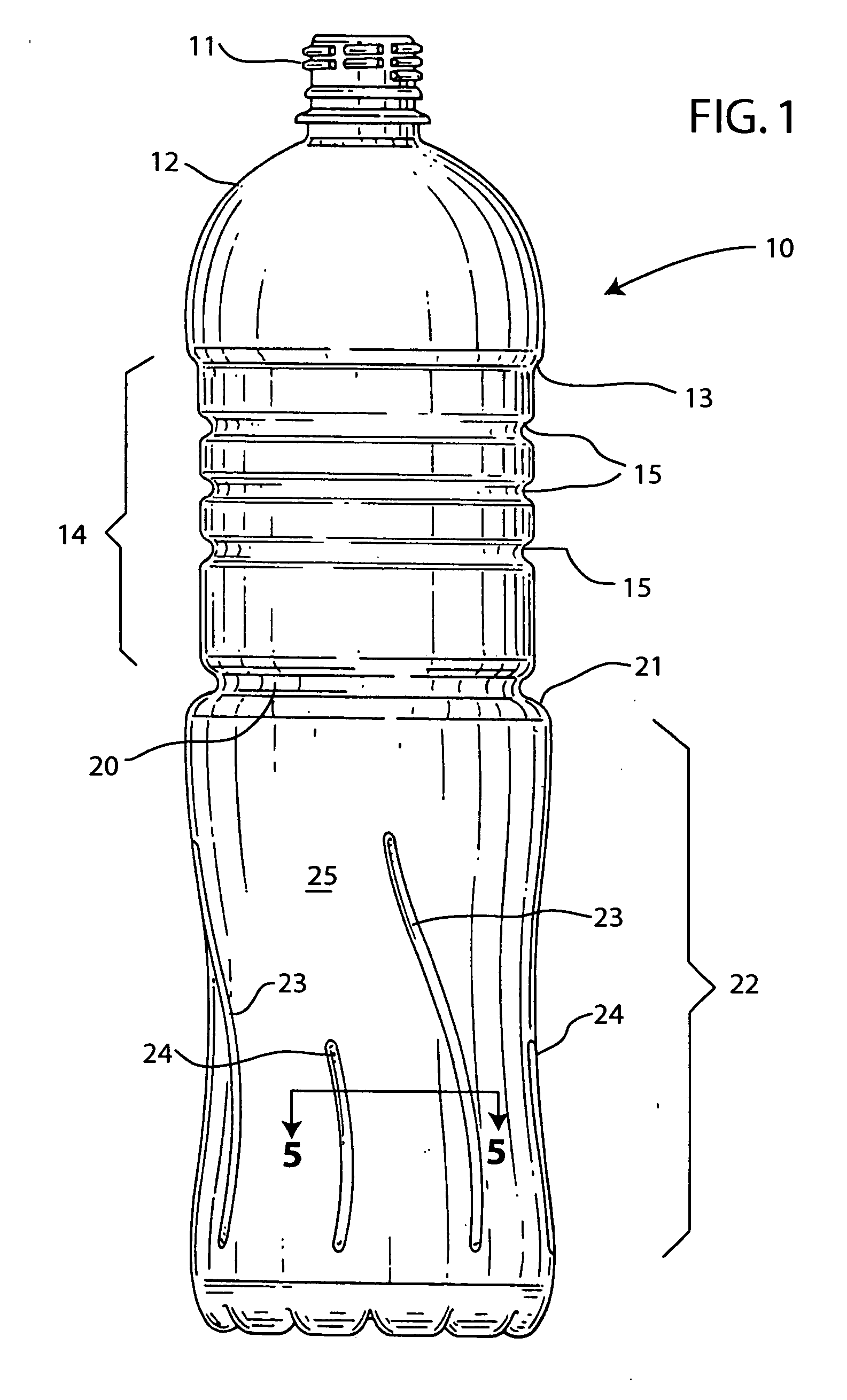

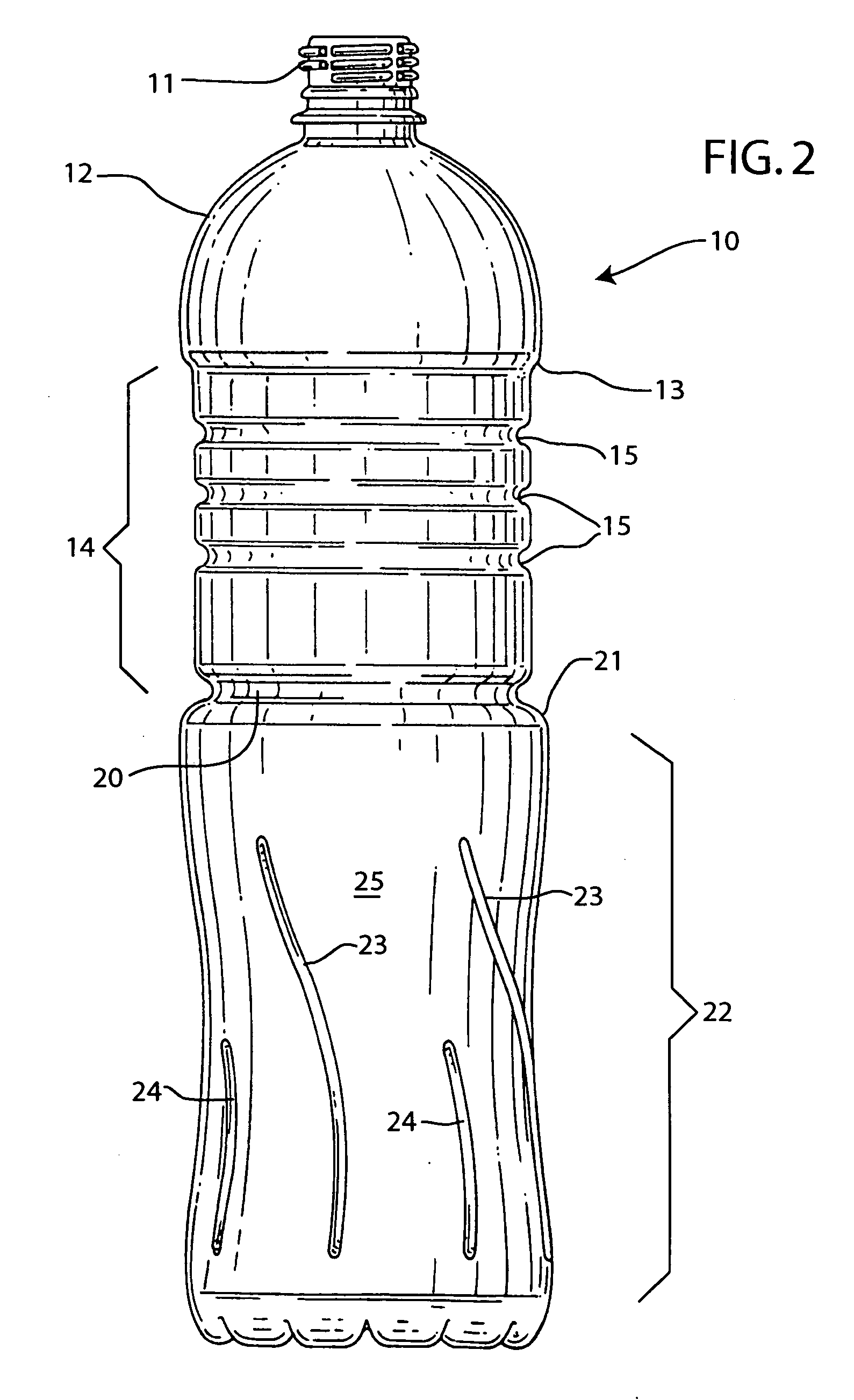

[0017] Referring to the drawings, like elements are represented by like numbers throughout the several views.

[0018]FIGS. 1 and 2 are essentially identical except that the right side elevational view of FIG. 2 is provided to better show the pattern of the swirl grooves in the bottom portion of the bottle.

[0019] The plastic bottle 10 is of the type intended for liquids such as beverages. The bottle includes a conventional threaded spout 11. Below the spout 11 is a shoulder 12 bounded at its lower end by a curved bottom 13 below which there is provided a label area 14 which has conventional horizontal reinforcing grooves 15.

[0020] Below the label area 14 is a main relatively deep horizontal circumferential groove 20 which includes a fairly large step 21 on the bottom thereof, which step leads to a bottom portion 22. The bottom portion 22 includes a plurality of relatively long vertical swirl grooves 23 which alternate with shorter swirl grooves 24. In the illustrated embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com