Hypereutectoid Rail Waist On-Line Heat Treatment Method and Constraint Device

A technology of heat treatment method and restraint device, applied in heat treatment furnaces, heat treatment equipment, furnaces, etc., can solve the problems of large amount of secondary cementite precipitation, no operation process, poor quality control, etc., to reduce residual stress and improve Comprehensive performance, the effect of suppressing the content of secondary cementite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

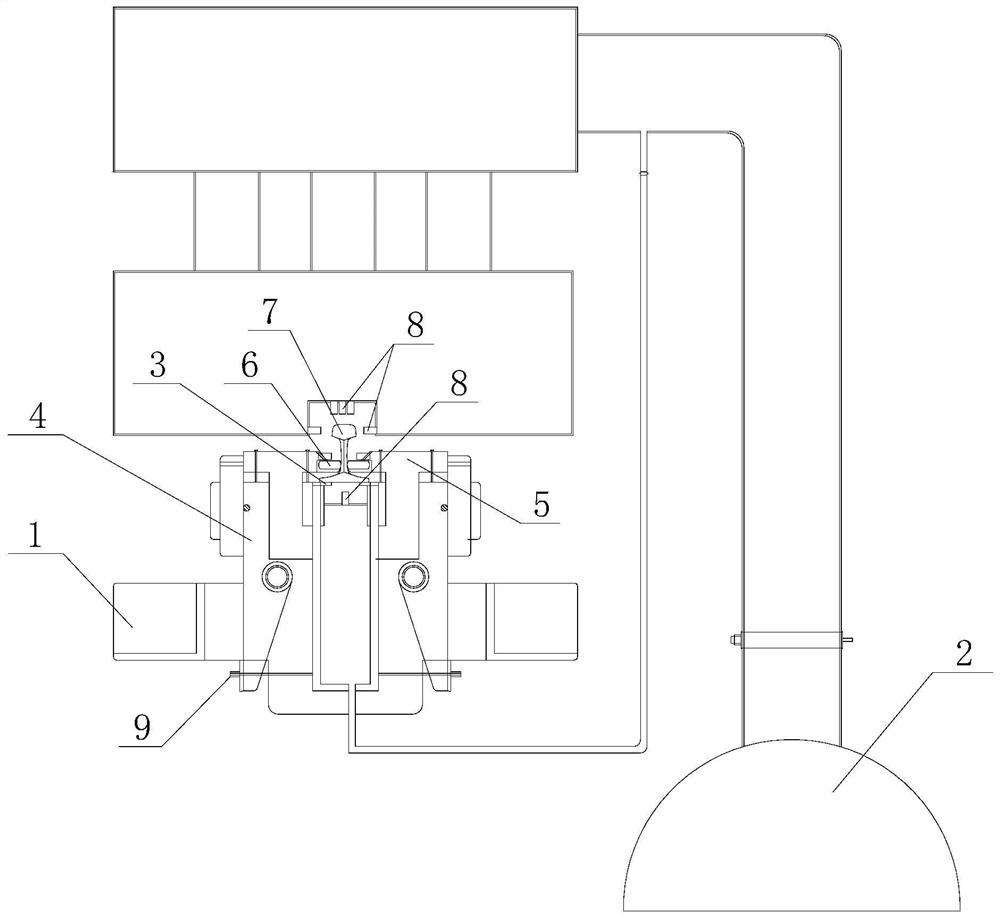

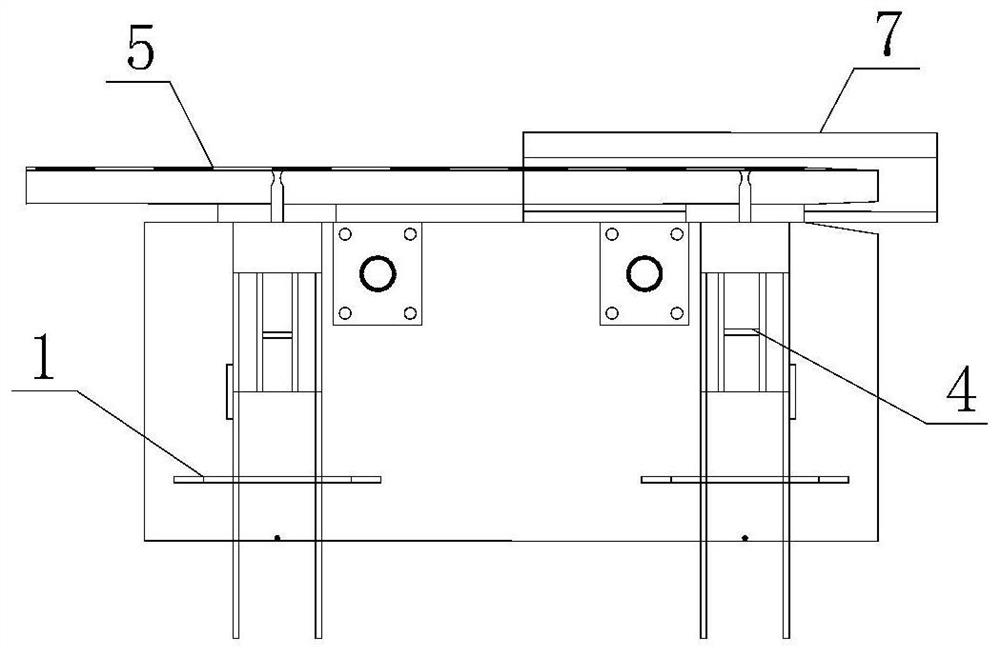

Method used

Image

Examples

Embodiment

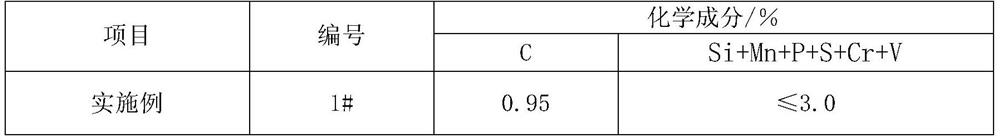

[0032] The embodiment of the present invention and the corresponding comparative examples all select the following chemical components of the rail.

[0033] Table 1 Example Rail Chemical Composition / %

[0034]

[0035] The comparative example among the present invention adopts the same chemical composition, heating and rolling process as the embodiment. The single weight of the rail is 75kg / m, the thickness of the rail waist is 20mm, and the temperature of the rail entering the unit is 760°C.

[0036] 1# to 4# are confinement devices using different processes (cooling speed of cooling medium) supplemented by different heat treatment processes, and 5# is a comparative example without heat treatment process. Subsequently, 5 samples were produced by the same heating and rolling process,

[0037] Table 2 Example and Comparative Example Rail Heat Treatment Process and Heat Treatment Constraint Device Used

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com