Vernier caliper for dimension measurement of rail profile

A vernier caliper and size detection technology, applied in the field of vernier calipers, can solve problems such as the measurement of rail section size, and achieve the effects of small impact, saving management costs, and uniform measurement benchmarks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

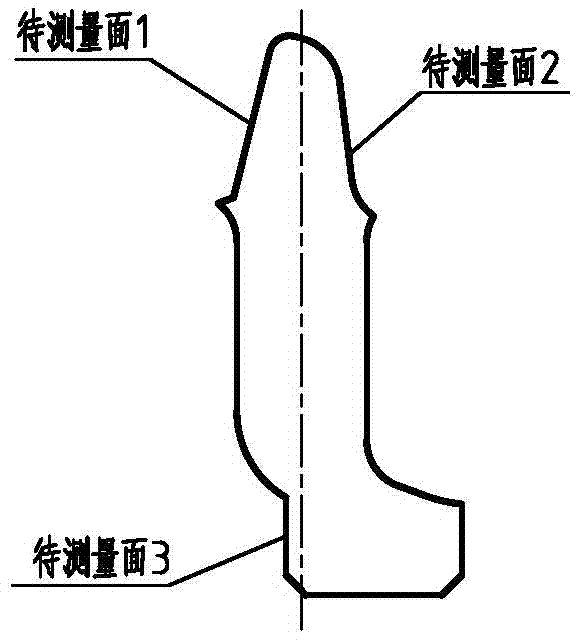

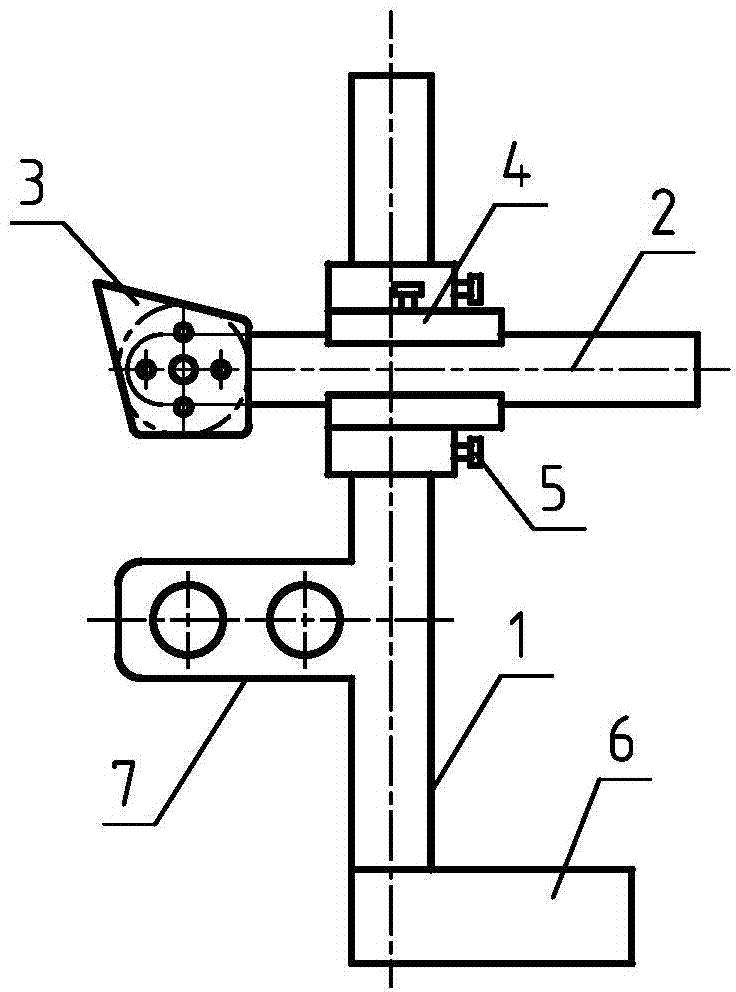

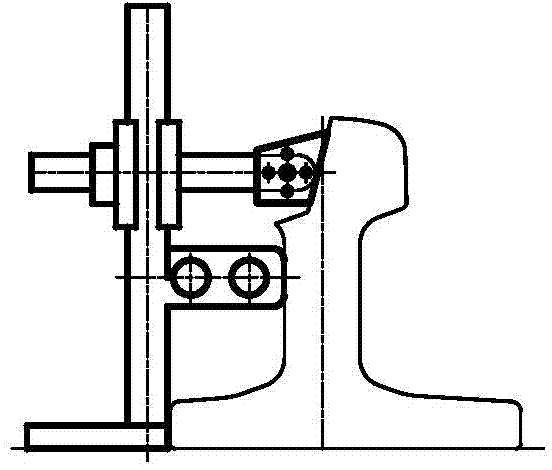

[0033] Such as figure 2 As shown, the vernier caliper used for rail section size detection is composed of two main scales; the height main scale 1 measures the height, and the depth main scale 2 measures the depth; the height main scale 1 and the depth main scale 2 are connected by the auxiliary scale of the two main scales , two pairs of chi constitute the support 4 of the vernier caliper at the same time, and the two pairs of chi are relatively fixed at a certain angle.

[0034] A polygonal measuring sheet 3 is fixed by screws on the depth main scale 2, and the measuring sheet 3 has different shapes according to the cross section of the rail section.

[0035] Each side of the measuring sheet 3 has a different inclination, and the measuring sheet 3 can rotate around the depth main ruler 2 to convert different inclined sides for measurement. The measuring sheet is provided with positioning holes, and the main ruler 2 is provided with positioning pins to realize the measuring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com