Stock rail and switch rail railhead configuration form

A structural form and basic rail technology, applied in the direction of tracks, rails, roads, etc., can solve the problems of high cost, frequent maintenance and replacement, and short service life of switch point rails, so as to improve strength, facilitate replacement, and reduce impact force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

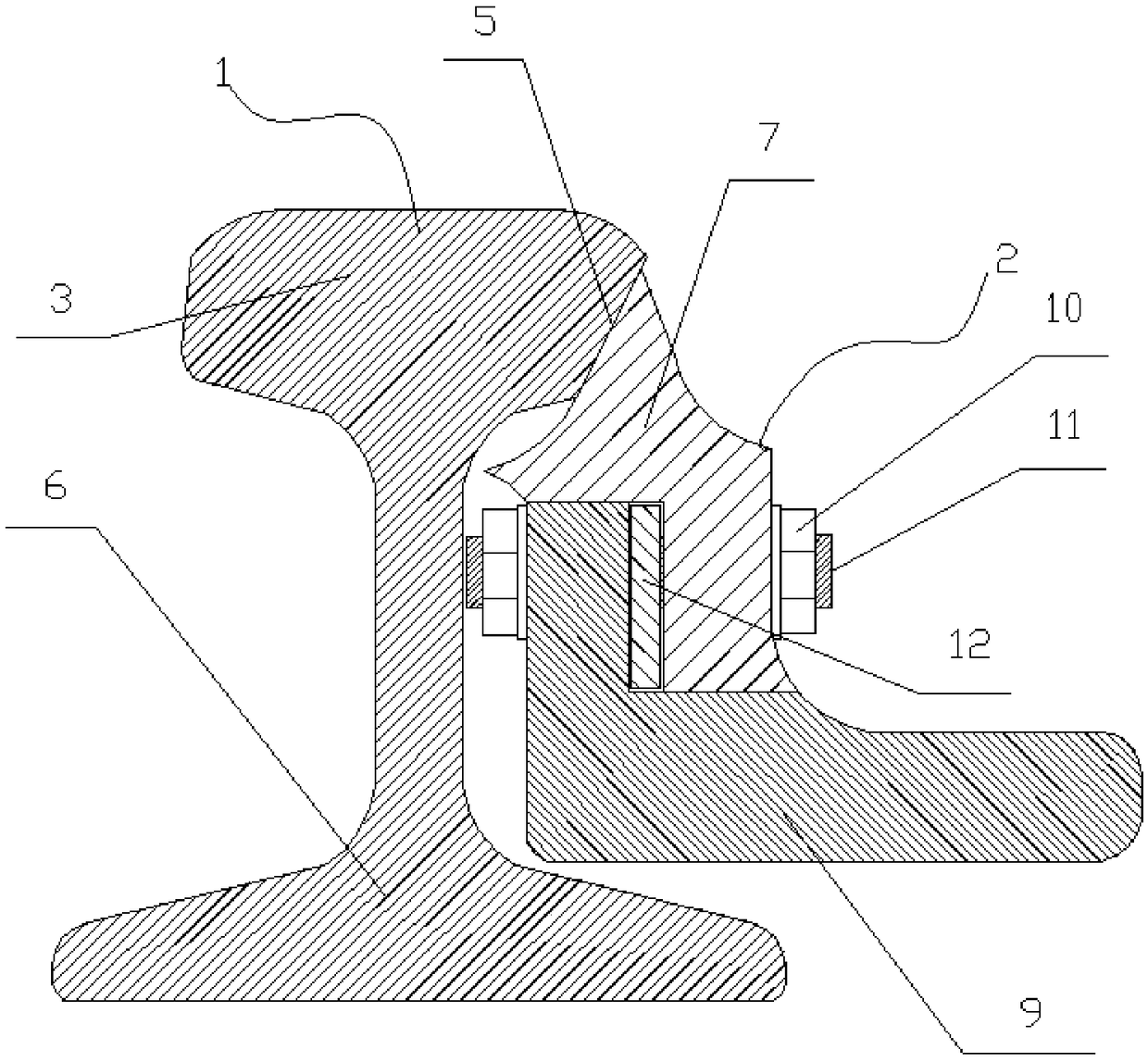

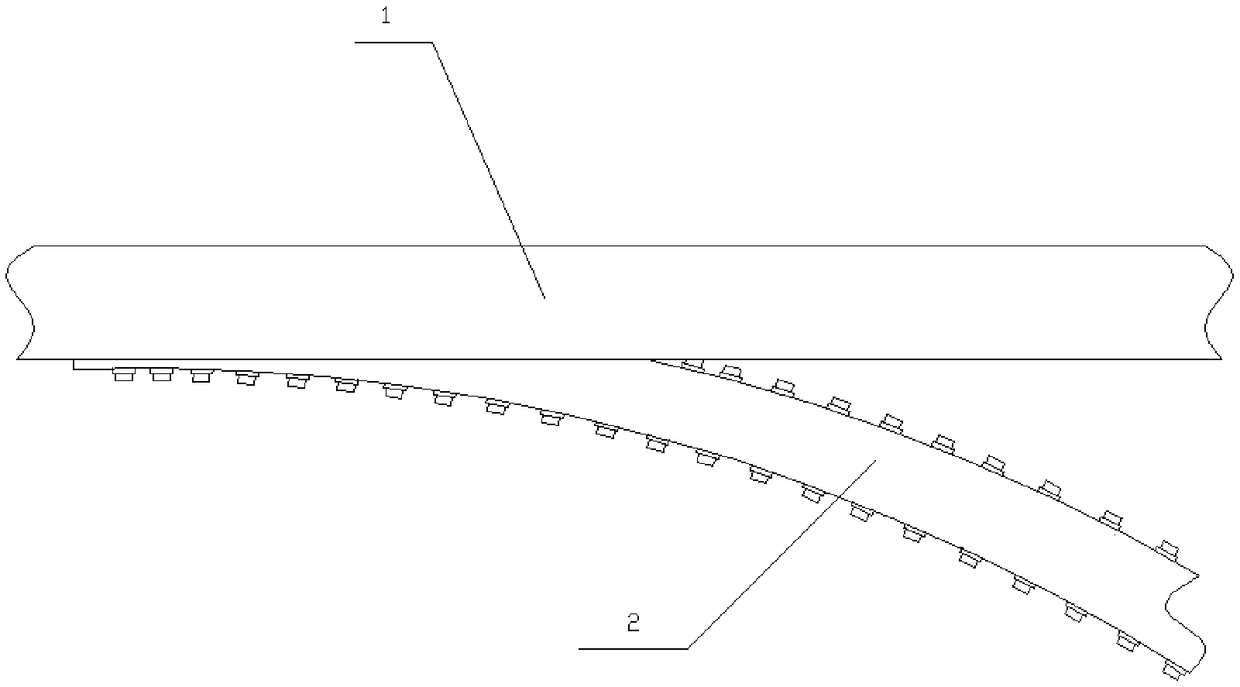

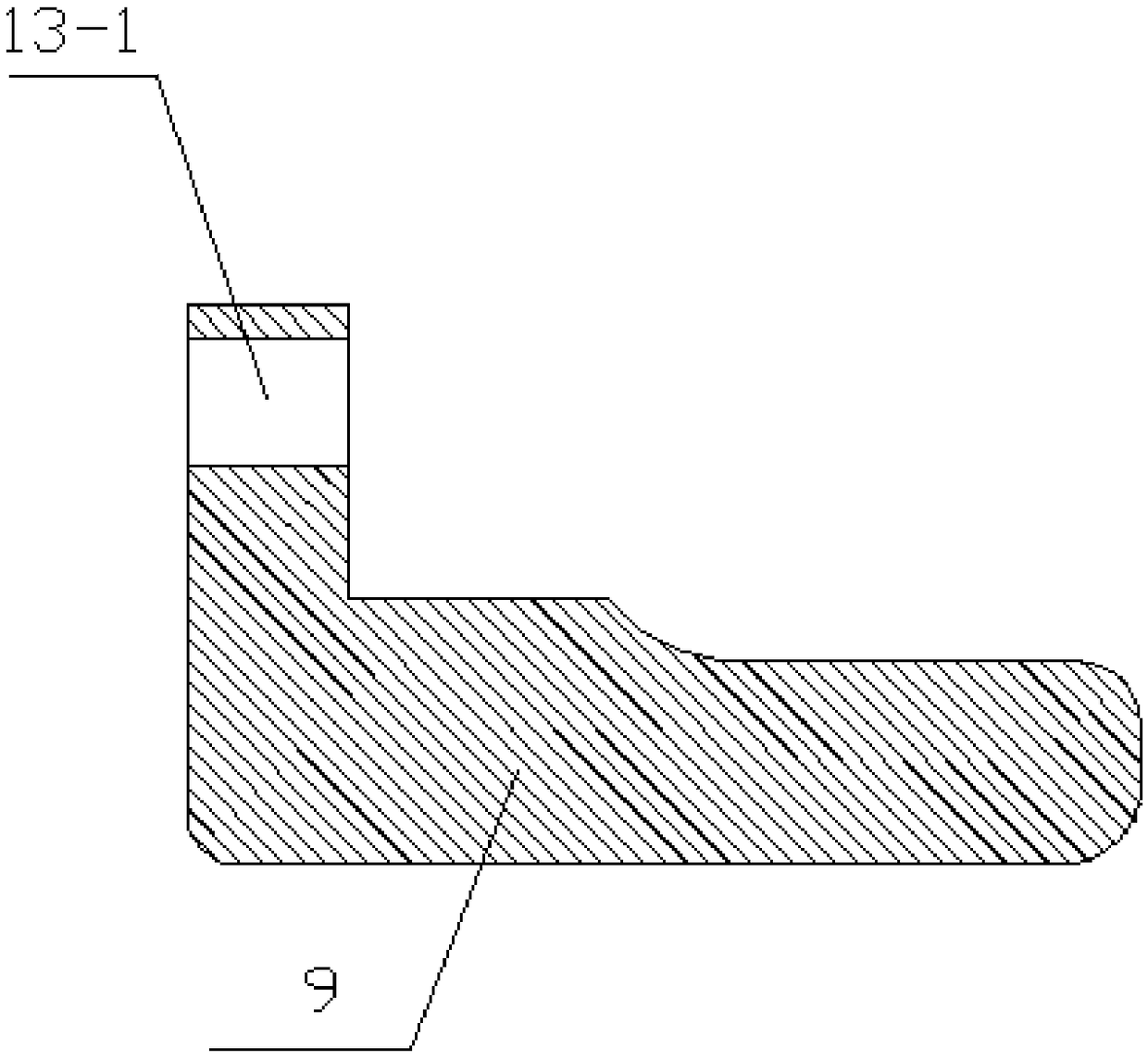

[0025] Such as Figure 1 to Figure 6 As shown, a basic rail and switch rail head construction form, including a basic rail 1 and a switch rail 2, the basic rail 1 includes a rail head 3 and a rail seat 6, and the rail head 3 is arranged above the rail seat 6 , the width of the rail head 3 is 10-20mm, the switch rail includes a switch rail head 7 and a switch rail base 9, the switch rail base 9 is "L" shaped, and the switch rail head 7 is located on Above the switch rail base 9, the switch rail head 7 is provided with a threaded hole 13-1, and the switch rail base 9 is provided with a threaded hole 2 13-2 communicating with the threaded hole 13-1, The rail head 3 is provided with a working side 5 that is in contact with the switch rail head 7, and the slope of the contact surface between the working side 5 and the switch rail head 7 is 1 / 5-1 / 3, and the working Side 5 is additionally processed 2-5mm inward, and the additional processing is divided into two sections, the length ...

Embodiment 2

[0034] Such as Figure 1 to Figure 6 As shown, a basic rail and switch rail head construction form, including a basic rail 1 and a switch rail 2, the basic rail 1 includes a rail head 3 and a rail seat 6, and the rail head 3 is arranged above the rail seat 6 , the width of the rail head 3 is 10-20mm, and the rail head 3 is provided with a working edge 5 that is in contact with the switch rail head 7 on the switch rail 2, and the working edge 5 is connected to the switch rail head 7 The inclination of the contact surface is 1 / 5-1 / 3, and the working edge 5 is additionally processed 2-5mm inward, and the additional processing is divided into two sections, the length of the first section is 50-200mm, and the second section The length is greater than 500, the inclination is 1 / 1000-1 / 300, and the tip 7 of the switch rail is 23mm lower than the outer edge of the wheel.

[0035] It should be noted that the threaded hole 13-1 and the threaded hole 2 13-2 are threadedly connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com