Compound railway track and construction method thereof

A construction method and composite technology, which can be used in the joints of roads, tracks, and rails, etc., can solve the problems of complex construction, high cost, and long process time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Introduce the present invention below in conjunction with accompanying drawing and embodiment.

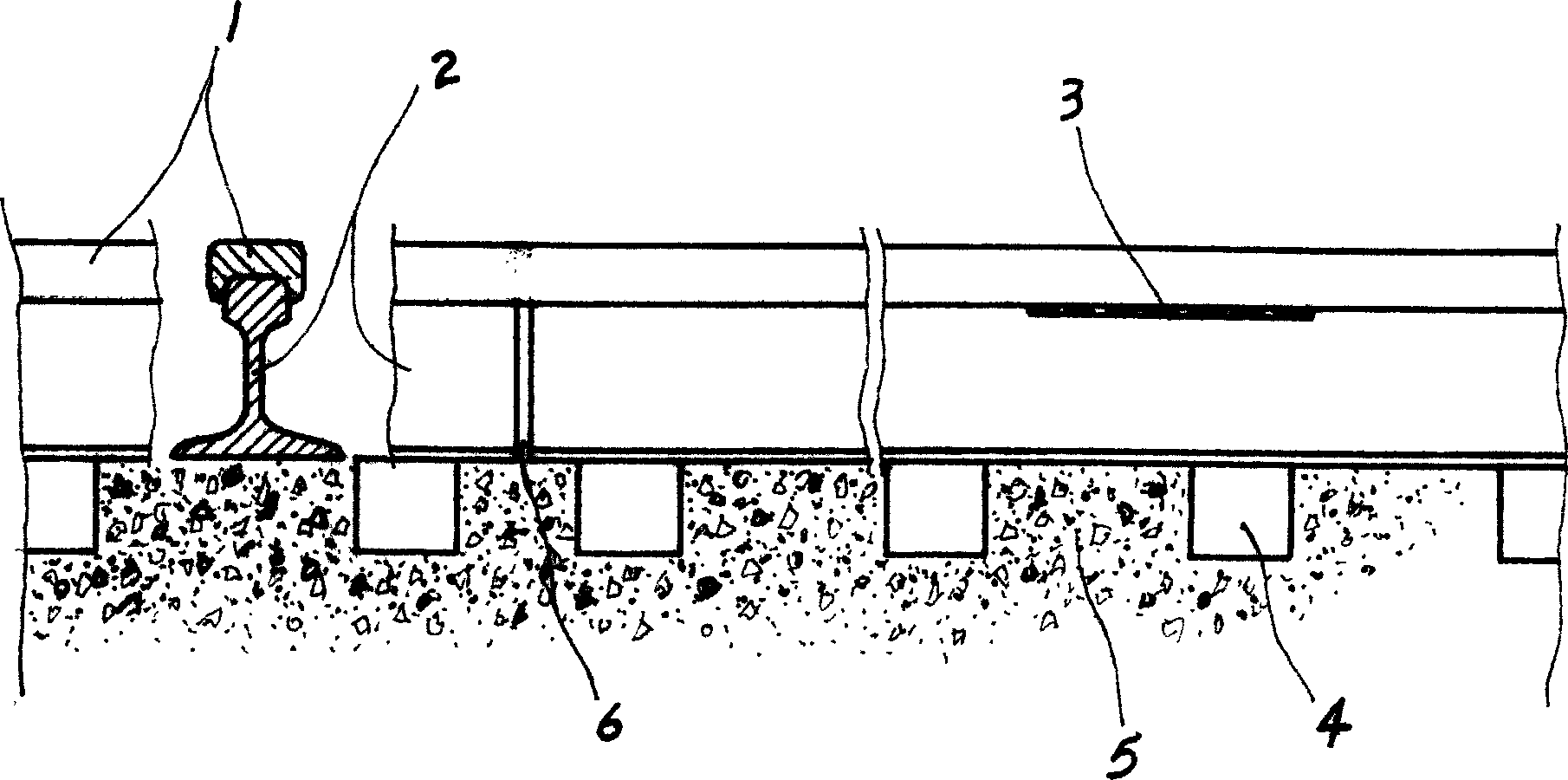

[0011] refer to figure 1 , the sleepers 4 arranged on the ballast bed 5 are laid with the steel rail 2 leaving the gap 6, which is a common quasi-gauge circuit. On the rail head of steel rail 2, is covered with a seamless rail 1. Below the seamless rail, there is a groove matching the 2 rail heads of the steel rail. The seamless rail is about 90mm wide, 25-45mm high, and 10-15mm deep in the groove. The joint part of the seamless rail 1 and the middle position of each steel rail 2 is a weld 3, and the weld seam is about 1m long, so that the seamless rail and the steel rail are firmly combined as a whole.

[0012] The construction method of the composite rail is: heat the seamless rail 1 to be laid so that its temperature is 20-35°C higher than the local annual maximum temperature. for welding.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com