Flame restriction strengthening device and method based on magnetic confinement and application

A technology of strengthening device and magnetic restraint, applied in lighting and heating equipment, combustion equipment, etc., can solve the problems of difficult burning intensity, unsafe refractory materials, and effectively restrain the flame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

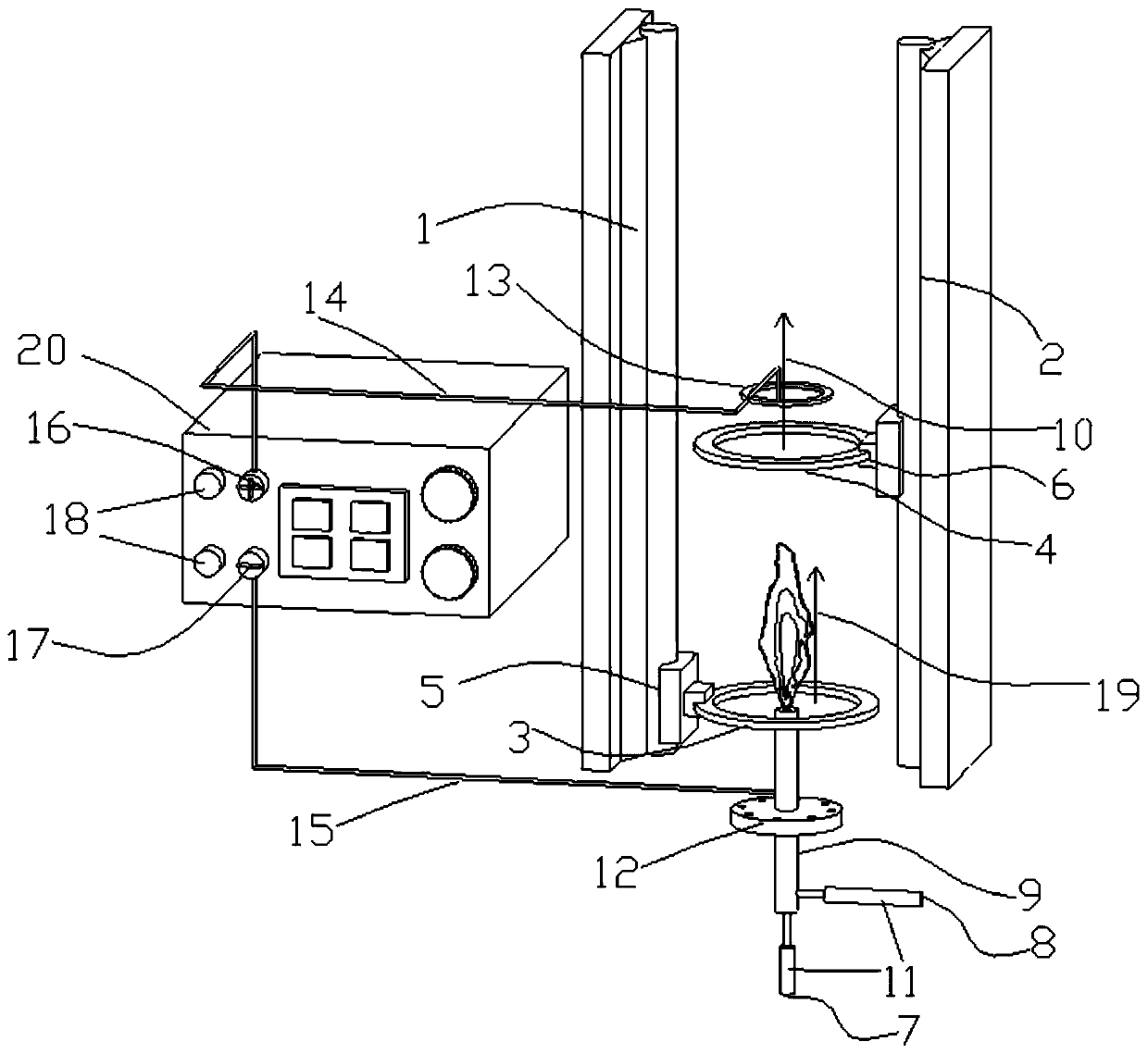

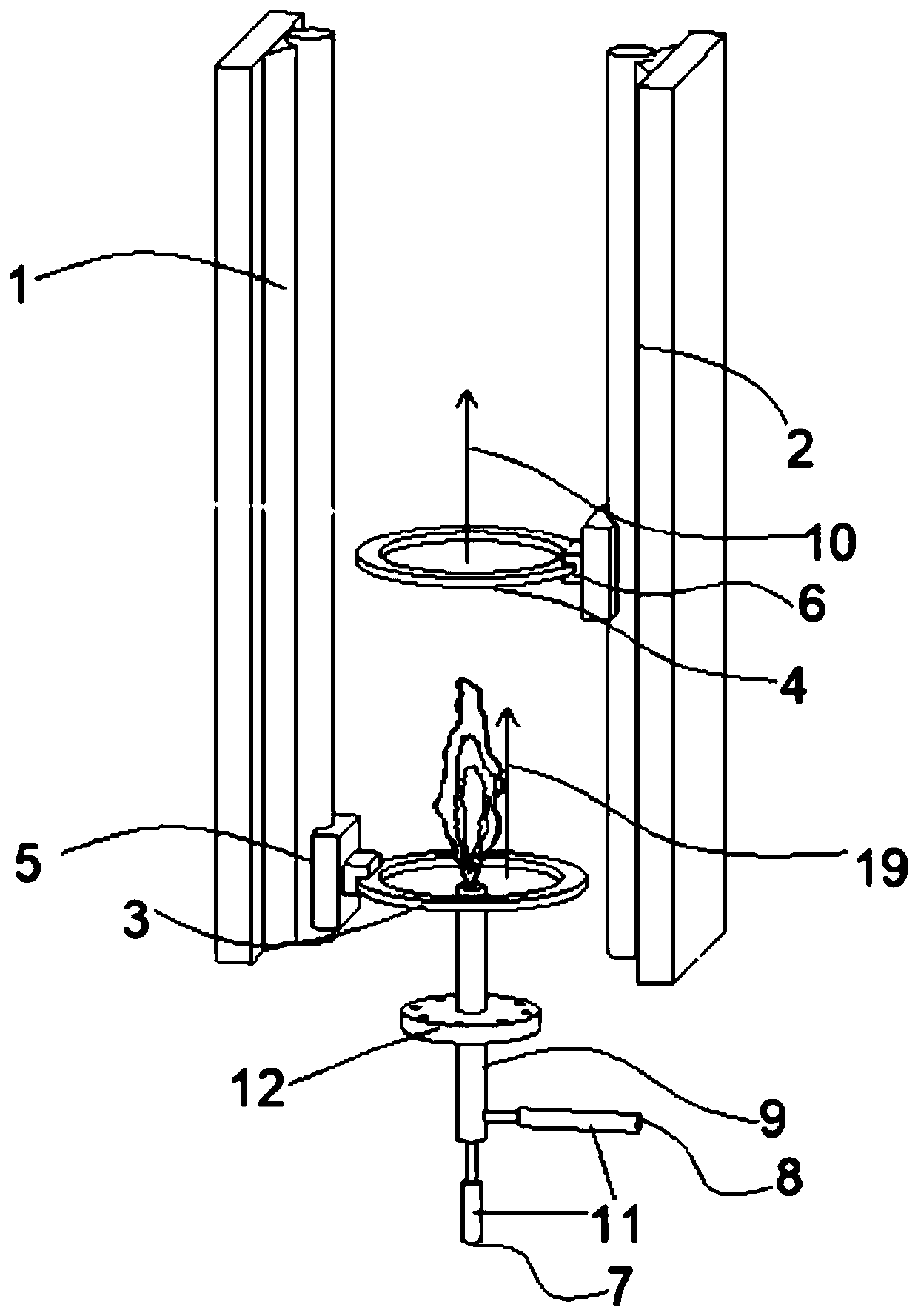

[0070] Such as figure 1 Shown is an embodiment of a combustion flame confinement enhancement device based on magnetic confinement. It includes the first guide rail 1 and the second guide rail 2 which are arranged oppositely, the first annular permanent magnet 3 (the magnetic poles are arranged in the following way: S pole to N pole from top to bottom along the central axis) and the second annular permanent magnet located above. Magnet 4 (the arrangement of magnetic poles is: S pole to N pole from top to bottom along the central axis), the first slider 5 and the second slider 6, which are arranged on the conductive magnetic pole in the area below the first annular permanent magnet 3 Nozzle 9 (in this embodiment, a nozzle with a stainless steel double channel structure), the nozzle 9 is provided with a nozzle insulating flange 12, and the nozzle insulating flange 12 made of polytetrafluoroethylene is connected to the nozzle bracket and kept insulated; There are nozzle inner cha...

Embodiment 2

[0077] The device in embodiment 1 is used to strengthen the confinement of the combustion flame. The molar flow ratio of methane gas and pure oxygen in the nozzle inner channel 7 and the nozzle outer channel 8 is 1:2, and an outer flame is formed at the outlet of the nozzle 9. Flames with temperatures up to 2850°C. The magnetic induction intensity of the magnetic mirror is the largest near the ring, about 0.05Wb / m2.

[0078] The nozzle 9 forms plasma in the high-temperature flame during the combustion process, and the flame enters the magnetic mirror formed by the magnetic fields of the first annular permanent magnet 3 and the second annular permanent magnet 4, and the plasma is bound by the magnetic field in the magnetic mirror to shuttle between the two permanent between the magnets, thereby forming a confinement of the burning flame. The spacing adjustment range of the first annular permanent magnet 3 and the second annular permanent magnet 4 is 600mm~30mm, and the adjustm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com