Corrosion fatigue crack detection system and use method thereof

A corrosion fatigue and crack detection technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problems that affect the measurement accuracy of the flexibility method, many variables, etc., and achieve a simple structure and a measurement range. Wide and easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in detail below, but the protection scope of the present invention is not limited to the embodiments.

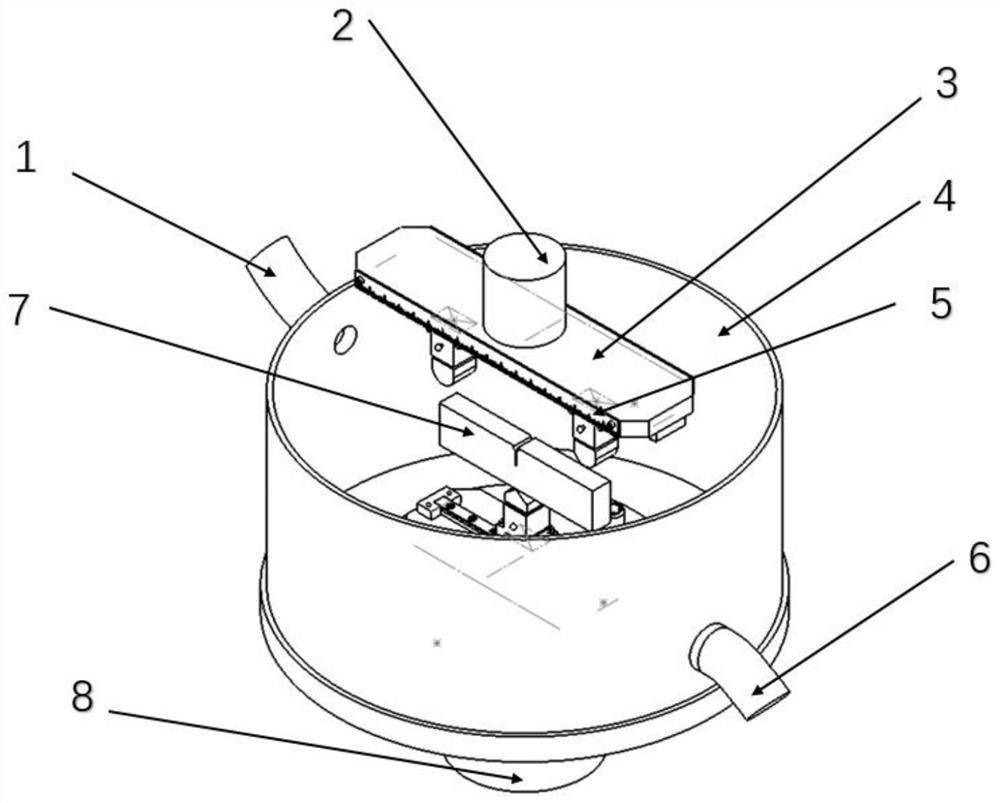

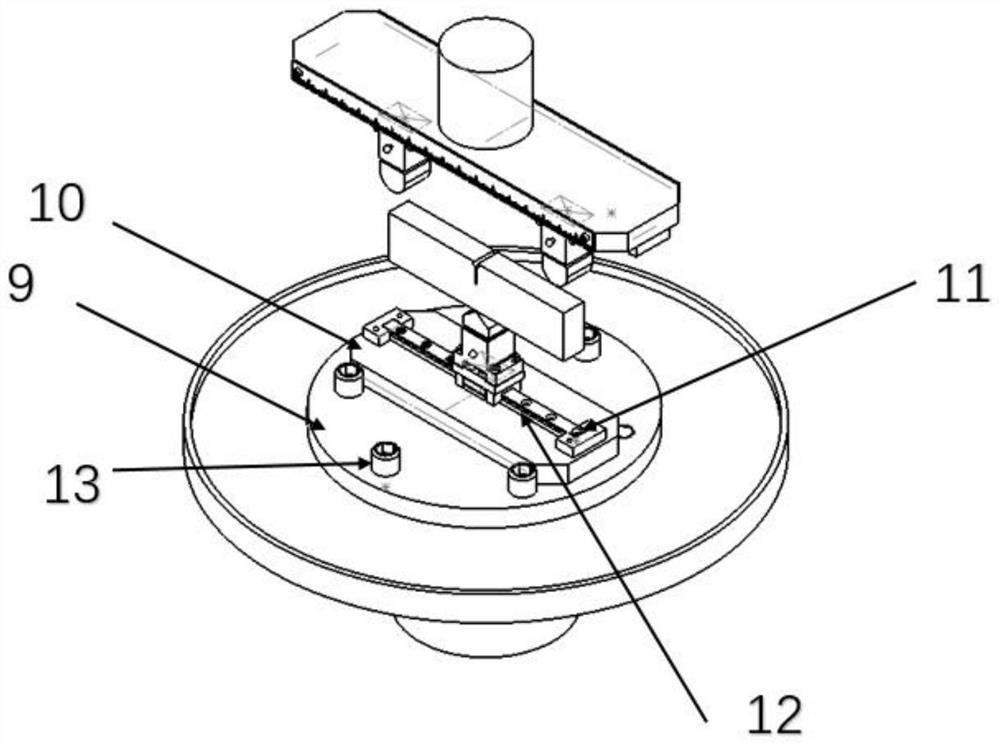

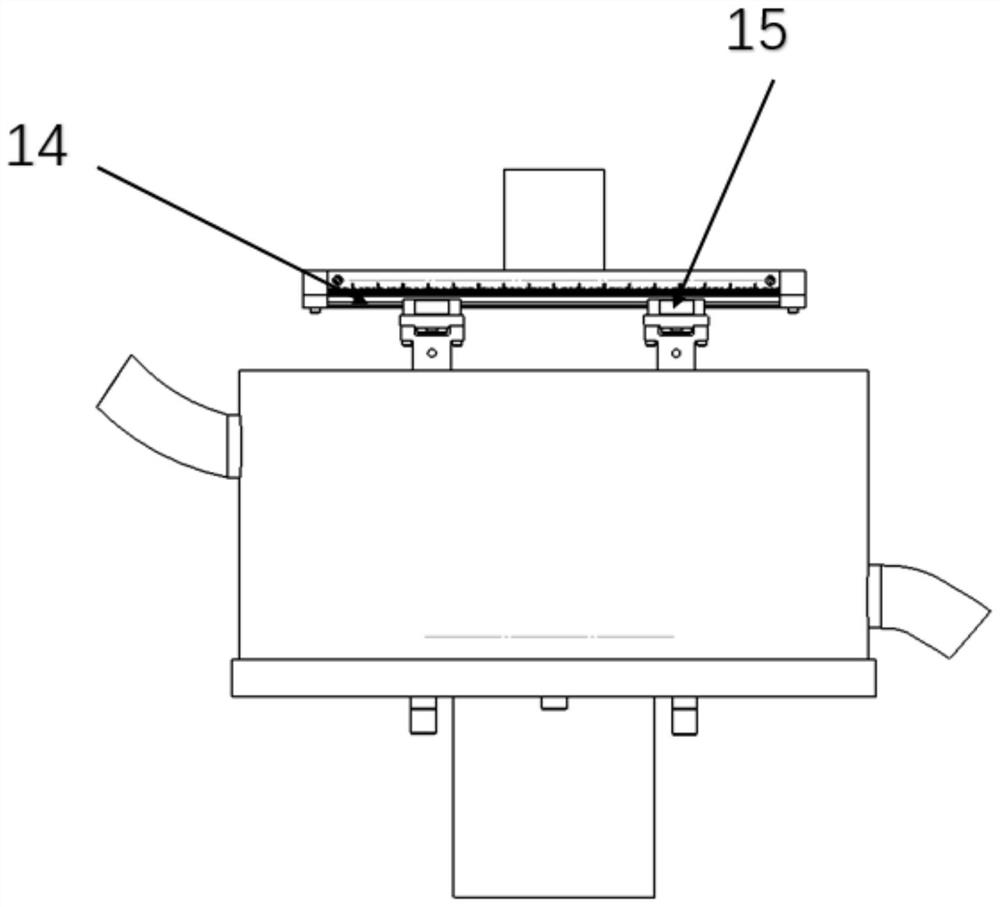

[0032] A corrosion fatigue crack detection system is designed for the corrosion fatigue crack growth test of bending specimens, and is mainly composed of a loading system, a corrosion solution processing system, and a crack detection system.

[0033] The loading system is mainly composed of a loading device and a clamping device. The corrosive liquid treatment system is composed of corrosive liquid tank, hose, suction pump and switch valve. A fixture with multiple loading conditions is provided. The position of the support roller can be changed through the slide block of the guide rail. A scale is installed on the side of the guide rail, and a limit block is installed on the slide block to realize the limitation and locking of the position of the support roller.

[0034] The corrosion fatigue crack de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com