Steel rail ultrasonic flaw detection vehicle

A flaw detection vehicle and ultrasonic technology, which is applied in the direction of material analysis, measurement device, and instrument using sonic/ultrasonic/infrasonic waves, can solve the problem that the ultrasonic probe cannot be effectively coupled with the rail head and both sides of the rail waist, which affects the detection effectiveness. , reliability, rail surface corrosion and other issues, to improve the detection accuracy and detection efficiency, reduce labor intensity, and use the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The accompanying drawings constituting a part of the present invention are used to provide further understanding of the present invention, and obviously, the described embodiments are only some embodiments of the present invention, rather than all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without creative efforts fall within the protection scope of the present invention.

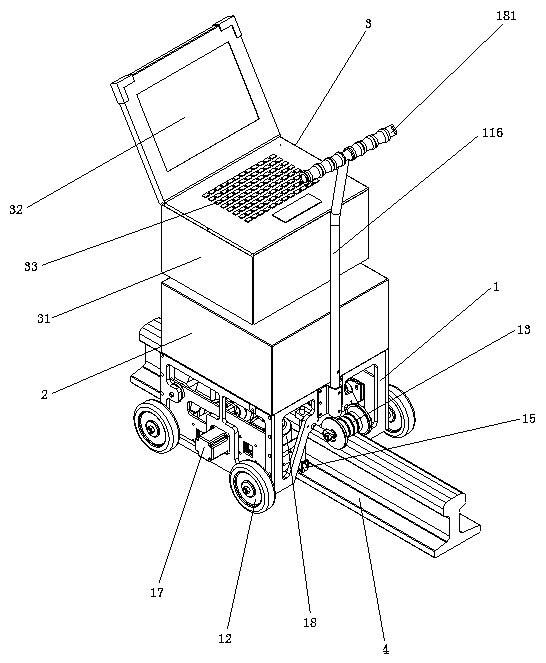

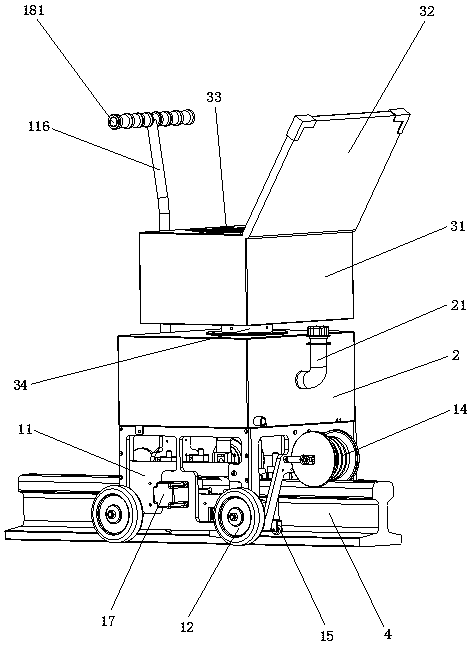

[0025] like Figures 1 to 7 As shown, the rail ultrasonic flaw detection vehicle of the present invention includes a flaw detection mechanism 1 , a water tank 2 and an industrial control host 3 .

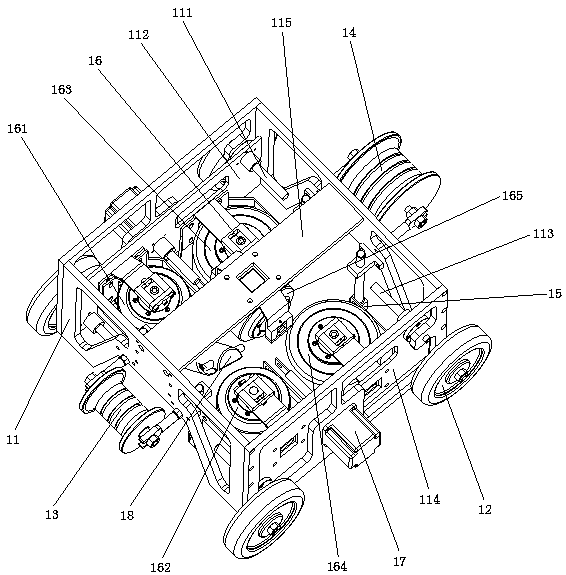

[0026] The flaw detection mechanism 1 includes a detection frame 11 , a land wheel 12 , a rear guide wheel 13 , a front encoder guide wheel 14 , an auxiliary support wheel 15 , a wheel probe 16 , a wheel probe stepper motor 17 and a couplant spray pump 18 .

[0027] The detection frame 11 is a cuboid frame structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com